| Duration: | May 2011 - April 2015 |

| Contracting Authority/ Sponsors: | European Union |

| Project Partners: | National Renewable Energy Lab (USA), Atlas-Ametek (USA), ITRI (Taiwan), FITI (Korea) |

| Project Focus: |

SOPHIA – UV Round Robin Test

UV Stability Tests of Module Back Sheets

Durability tests for materials contain UV stability tests, mainly for polymers. Type approval of PV modules according to the IEC 61215 and IEC 61646 standards contains so-called UV preconditioning with a dose of 15 kWh/m², which does not have any connection to actually occurring loads. Here, 3 - 10 % of the UV radiation must be in the wavelength range between 280 nm and 320 nm. As the materials to be tested react very sensitively to spectral differences, the spectral distribution of the radiation sources is of utmost importance. If the UV content is increased compared to the solar spectrum, the sample temperature should always be captured to avoid sample overheating and thus misinterpretation.

Fraunhofer ISE organized a comparison of different UV sources at different test laboratories based on several back sheet types. The main question of this round robin was the investigation of the interactions of UV radiation with polymer materials used in PV modules.

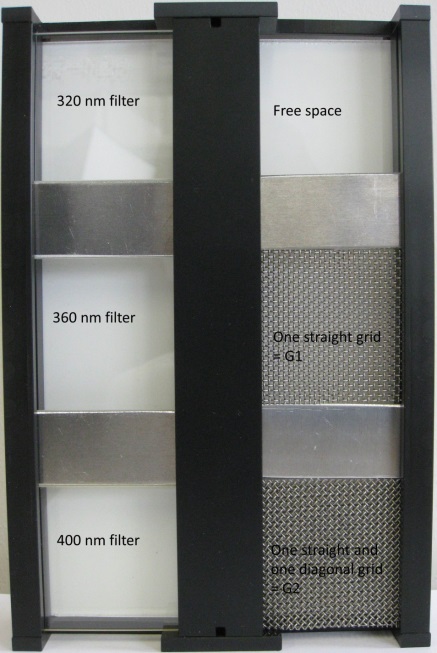

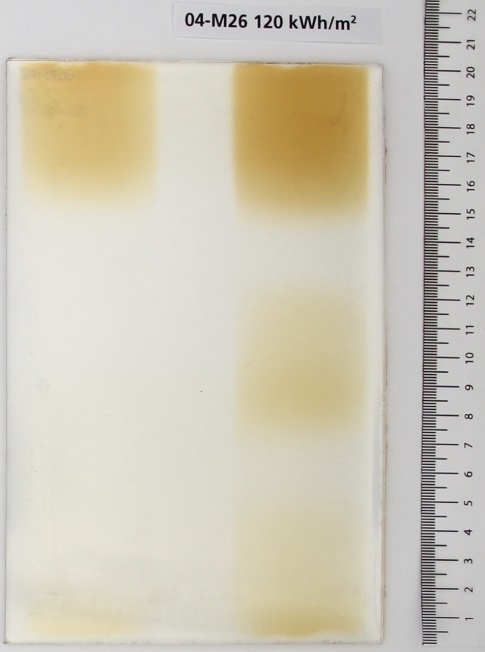

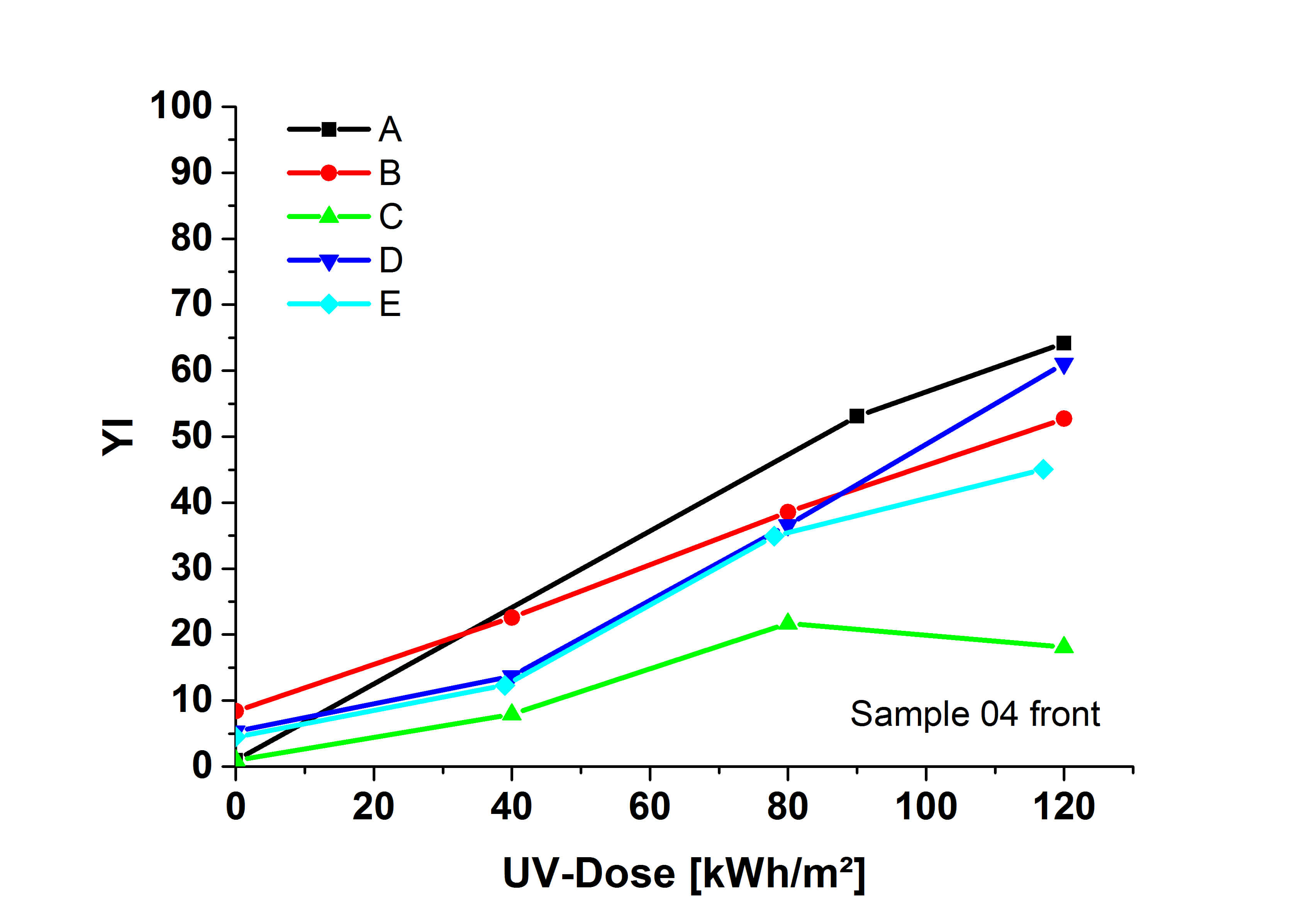

For this purpose, an EVA encapsulation material and seven different backside sheet laminates were produced of solar glass (130 mm x 200 mm). These samples were exposed in a specifically prepared sample holder with three edge filters and two intensity filters (grids) at the different laboratories for the investigation of spectral material sensitivity. The sample temperature was measured using temperature sensors. Material aging was quantified using reflection and transmission measurements and the calculation of the yellowness index.

Here, significant differences were found in the spectral-related aging behavior of the different laminates. For example, the yellowness indexes of identical samples showed differences of up to 300 % for aging at different labs. However, with respect to excessive UV aging, a very good correlation could be found of the change in the yellowness index between more or less excessive UV aging conditions.