| Duration: | September 2012 - November 2015 |

| Contracting Authority/ Sponsors: | Initially Federal Ministry for the Environment, Nature Conservation and Nuclear Safety (BMU), later Federal Ministry for Economic Affairs and Energy, Projektträger Jülich |

| Project Partners: | University of Applied Sciences Stuttgart, ILK (Institute for Air Conditioning and Refrigeration) Dresden, EAW Energieanlagenbau GmbH Westenfeld, Invensor, Sortech AG, Thermofin GmbH, Hindenburg Consulting, GreenChiller e. V. |

| Website: | www.solarueck.de |

| Project Focus: |

SolaRück – Efficient Heat Exchange for Solar Thermally Driven Refrigeration Generation

Heat rejection is of essential importance for refrigeration. However, the influence of the heat rejection unit on the performance is much more critical for thermally driven processes than for electrically driven processes. The reasons are that the amount of waste heat to be dissipated to the ambient is higher for thermally driven processes due to thermodynamic reasons, and that these processes react more sensibly to higher heat rejection temperatures. The objective of the collaborative “SolaRück” project is the development of optimized heat rejection processes. This shall promote a wider distribution of (solar) thermal cooling and a sustainable market development.

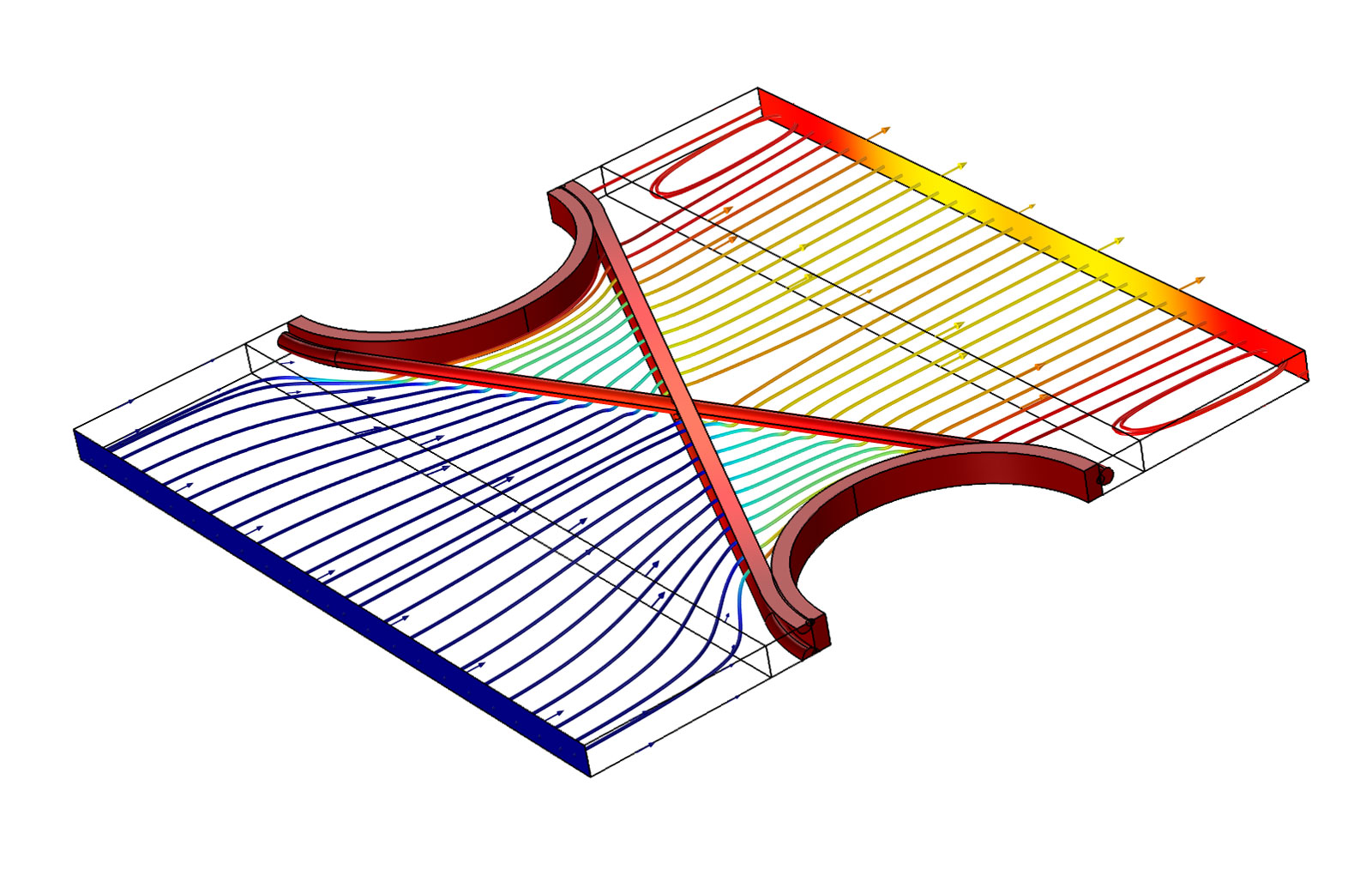

The three involved research institutes analyze the operation of heat rejection units in existing cooling systems in detail in three fundamental topic areas. They also investigate two different approaches for increasing the heat rejection capacity while reducing the required auxiliary energy at the same time (heat exchanger based on wire-mesh structures and adiabatic pre-cooling of air). Additionally the institutes use simulations to develop optimized generic operating strategies for (solar) thermal cooling systems, which are tested on real systems subsequently.

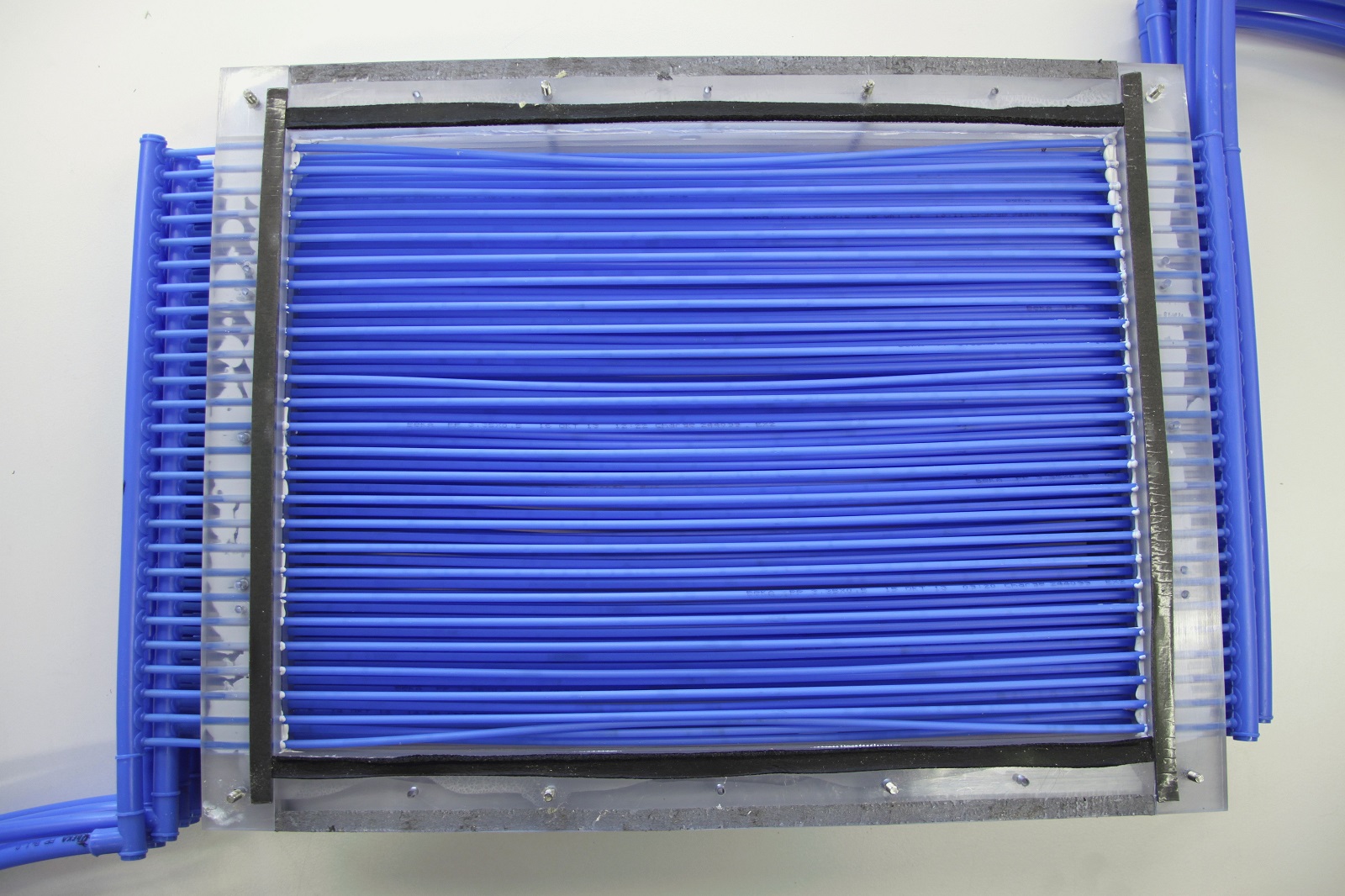

The companies involved in the project develop prototypes for innovative heat rejection units in the small capacity range in three application-oriented work packages: EAW GmbH develops a method for adiabatic air pre-cooling for lowering the cooling water temperature under high ambient temperatures together with ILK Dresden and Thermofin. Invensor GmbH together with Hindenburg Consulting works on the development of a hybrid cooler for small capacities with minimum maintenance effort. The development of SorTech AG together with Fraunhofer ISE focusses on dry coolers based on polymer materials for weight and cost reductions.