| Duration: | 04/2017-12/2020 |

| Contracting Authority/ Sponsors: | Bundesministerium für Wirtschaft und Energie (BMWi) |

| Project Partners: | STS Spezial-Transformatoren Stockach GmbH, Semikron Elektronik GmbH & Co. KG |

| Project Focus: |

SiC-MSBat

Medium-voltage Converter with High-voltage SiC Power Modules for Large-scale Storages and System-serving Distribution Grids

As the energy transition progresses, the expansion of power grids is becoming increasingly important. More and more renewable generation systems as well as electrical storage systems are being connected to the grid. This gives power electronics a decisive role, because it is necessary to connect these systems to the grid. However, in addition to the pure feed-in or feed-back of electrical energy, power electronics must also perform other grid-supporting tasks. In the "SiC-MSBat" project, researchers at the Fraunhofer Institute for Solar Energy Systems ISE and partners have developed and successfully commissioned a highly compact inverter for direct feeding into the medium-voltage grid.

Currently, inverters mostly feed into the low-voltage grid. They are then coupled to the medium-voltage grid via large 50 Hz transformers. The use of new types of silicon carbide (SiC) transistors with very high blocking voltages now makes it possible to connect inverters directly to the medium-voltage grid. Thanks to their high control dynamics, SiC inverters can take on grid-stabilizing tasks and act as active grid filters, for example. Furthermore, very high power densities can be achieved with their help.

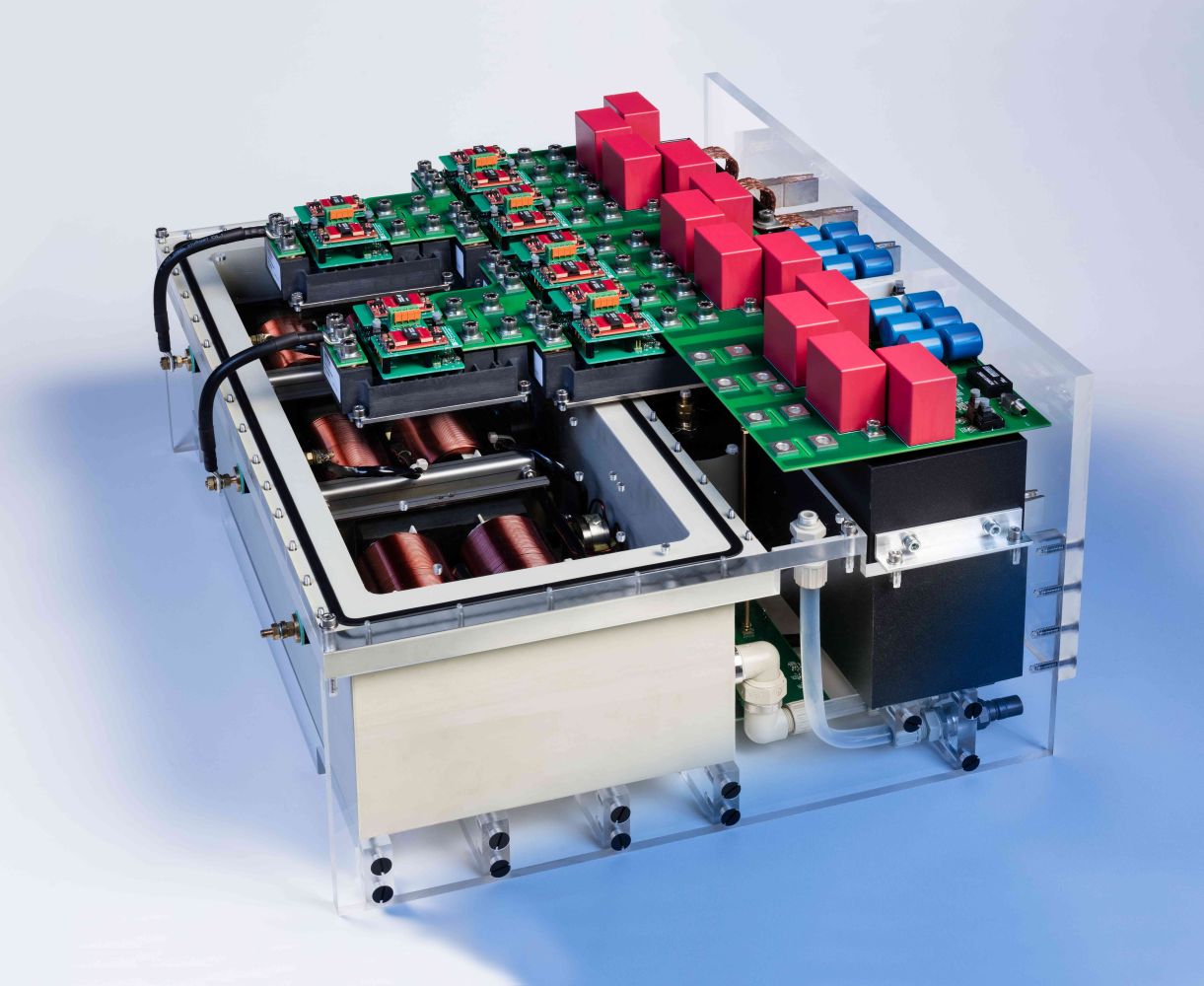

As part of the project, a 250-kW inverter stack was developed for feeding into 3-kV AC grids. Novel 3.3-kV SiC transistors are used. These have significantly lower power dissipation than comparable silicon transistors and therefore allow the inverter stack to be clocked at a switching frequency of 16 kHz. Compared with state-of-the-art silicon transistors, this corresponds to a switching frequency 10 times higher in this voltage class. The high switching frequency enables savings in the passive components because they can be dimensioned smaller. Another special feature of the inverter is its active liquid cooling, in which a synthetic ester serves as the cooling medium. The cooling medium is pumped through the inverter and cools both the transistors and the filter chokes, which are housed in a closed tank, via a liquid heat sink. At the same time, it serves as an electrical insulation medium for the filter chokes, allowing them to be made more compact.

The inverter was built and tested in the Fraunhofer ISE laboratories, achieving a very high efficiency of 98.4 % at the rated power. The design of the device allows modular interconnection of multiple inverter stacks to achieve system outputs of several megawatts.