| Duration: | 06/2020 - 05/2024 |

| Contracting Authority/ Sponsors: |

European Commission - Horizon 2020; Call: H2020-SC5-2018-2019-2020 Greening the economy in line with the Sustainable Development Goals (SDGs); Topic: SC5-09-2018-2019; Type of action: RIA |

| Project Partners: | - Universita degli Studi di Palermo – IT - Insituto de Biologia Experimental e Tecnologica – PT - Universitat Politecnica de Catalunya – ES - Ecole Nationale D’Ingenieurs de Gabes – TN - Suez Groupe – FR - Resourseas S.R.L. - IT - Ekodenge Muhendislik Mimarlik Danismanlik Ticaret Anonim Sirketi – TR - Intrigo limited – IE - Sosalt SpA – IT - Teknologian tutkimuskeskus VTT Oy -FI |

| Project Focus: | |

| Website: | SEArcularMINE |

SEArcularMINE – Extracting Raw Materials From Concentrated Sea Water

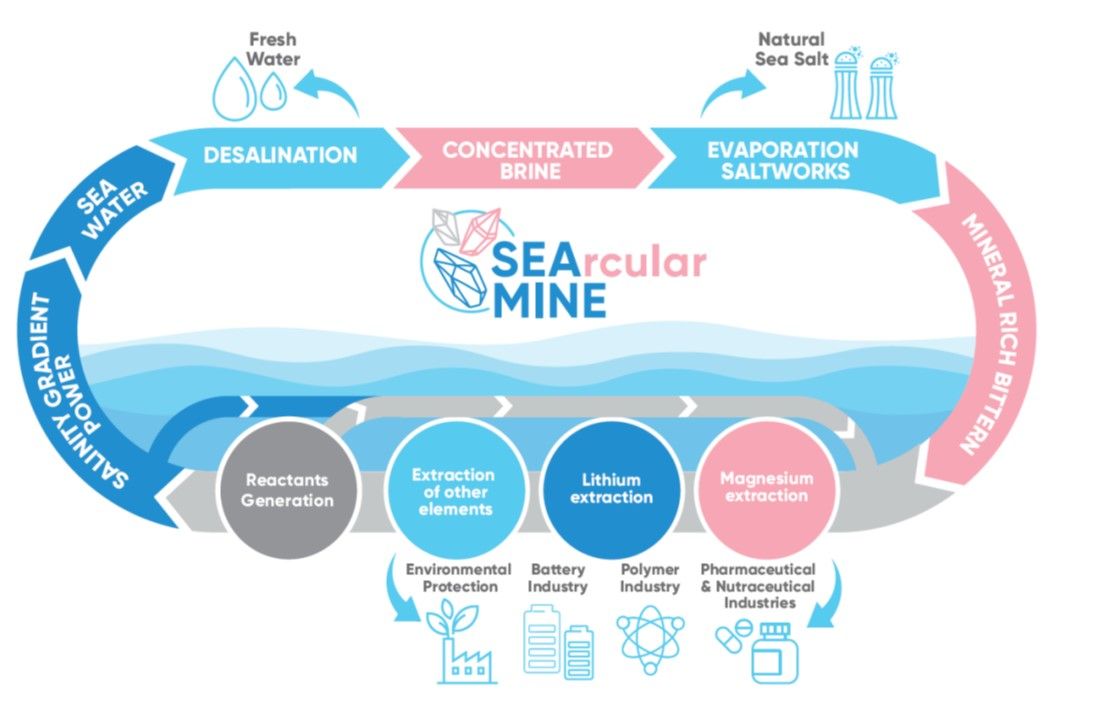

Circular Processing of Seawater Brines from Saltworks for Recovery of Valuable Raw Materials

Europe currently depends on imports of raw materials critical for economic development. These Critical Raw Materials (CRM) are increasingly needed in many high growth sectors, e.g. battery technol., polymers, pharmaceutics and nutraceutics. There is an urgent need for innovation allowing for CRM production in Europe meeting highest expectations in terms of performance, cost and green credentials.

SEArcularMINE will prototype an innovative integrated process recovering energy and CRM such as magnesium, lithium, rubidium and other trace elements (TE), from waste brines in Mediterranean basin saltworks. The project will target very low energy consumption, alongside using novel technology to generate electricity from salinity gradients of seawater. The circular approach maximises resource efficiency and economic viability.

Project objectives

SEArcularMINE builds on the ancient and still widely used process of saltworks, where seawater goes through natural evaporation and crystallization in shallow basins. The resulting brine (bittern) contains high concentrations of valuable trace elements (TE). The project will develop sustainable and cost-effective technologies that will contribute to securing European access to CRMs through a circular processing of the abundant bittern resources. The consortium brings together leading experts from academia and industry to:

- Develop 3 innovative technologies to target the extraction of Magnesium (Mg), Lithium (Li) and other trace-elements (Rb, Sr, Cs, Ga, Ge, Co)

- Establish multiple auxiliary processes to provide full circularity during the production process

- Produce the required energy from salinity gradient power and on-site solar and wind energy

- Generate modelling tools for simulation, sizing and evaluation of the processes to ensure optimal use of the resource for given framework conditions

- Characterize and map bittern availability in Europe and the whole Mediterranean basin

- Pave the way for further development, ensuring wide adoption and acceptance.

Expected impacts

SEArcularMINE’s circular process concept will utilize waste streams and current infrastructure, safeguard environmental sustainability and contribute to the following impacts:

- Secure sustainable access to Mg, Li and other trace elements within the EU

- Support the transition to a clean, low carbon economy via advanced technological development reliant on CRM access

- Create a technology base for radical innovations that would help unlock substantial reserves of new or currently unexploited resources within the EU

- Present an alternative to the high environmental costs of current extraction of finite global reserves, through a circular process which uses only seawater as an input, eliminates any requirements for external chemicals and strives to bring the demand for energy and freshwater close to zero

- Mitigate freshwater scarcity at low cost by trialing the integration of the technologies with seawater desalination.

In this collaborative project, Fraunhofer ISE will

- Develop an efficient approach for the pre-concentration of Li/TE rich highly saline brines involving saturation induced precipitation and extraction of major salts

- Provide technological support in design, construction and testing of a lithium selective separation prototype

- Perform analysis and characterization of different selective post-concentration technologies (e.g. MD, FO) to be applied with Li/TE rich brines after selective recovery step from the brine stream

- Perform fundamental research on reactive crystallization processes for the selective precipitation of Li and TEs

- Develop and operate a continuous operation Li/TE crystallization prototype

- Validate physical and chemical modelling approaches and adapt simulation tools.