| Duration: | 05/2021 - 10/2026 |

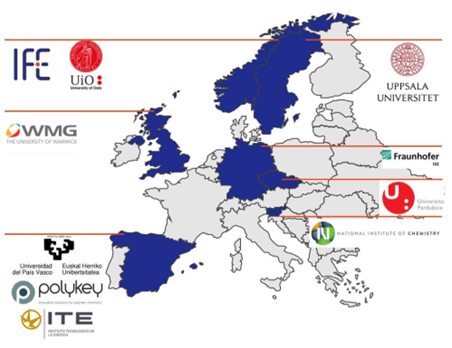

| Contracting Authority/ Sponsors: | This project was funded by the European Union's Horizon Europe research and innovation program under grant agreement Nº 101104028. |

| Project Partners: | Institutt for Energieteknilkk, Universitetet i Oslo , Universidad del Pais Vasco / Euskal Herriko Unibertsitatea, Polykey Polymers SL, Uppsala Universitetet, Kemijski Institut, Univerzita Pardubice, Asociacion Instituto Tecnologico de la Energia, IFE Invest |

| Website: | salamander-eu.com |

| Project Focus: |

SALAMANDER

Smart Sensors and Self-Healing Functionalities Embedded for Battery Longevity with Manufacturability and Economical Recyclability

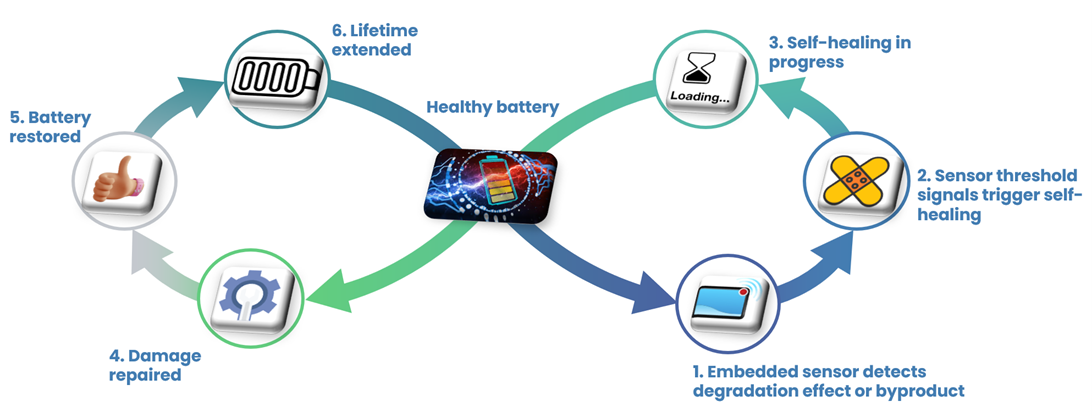

Within the SALAMANDER project, sensors (embedded sensors) and self-healing functionalities for Li-ion batteries (LIB) are developed and integrated into them to improve quality, reliability and lifetime.

This will be enabled by smart battery characteristics that, triggered by internal sensors or evaluation of operational data in battery management, analyze indicators of their own degradation and react autonomously with external stimuli to trigger self-healing functionalities when needed.

To achieve this goal, the project envisions different types of sensors with two self-healing functionalities to counter the most threatening and damaging responses that occur in a typical LIB.

To strengthen the goal of the BATTERY 2030+ initiative for a competitive and sustainable value chain in the European battery industry and the circular economy, disruptive measures such as those in the SALAMANDER project are needed to massively increase the lifetime of batteries.

A printed resistance sensor array on the silicon-carbon composite anode enables cracks in the material to be detected. Self-healing polymers that can be thermally activated enable the self-healing process on the anode to be initiated and the silicon nanoparticles to be re-bonded.

Degradation on the cathode is caused by the detachment of Mn ions from the LiNiMnCoO2(NMC) cathode. This process is detected by an electrochemical sensor applied to the separator. As soon as this happens, a process is thermally triggered that releases so-called scavenger substances. These substances serve to rebind the released Mn ions.

The sensors and materials are assembled into cells and integrated with a battery management system to form a battery module.

Within the SALAMANDER project, the development of the battery management system is the responsibility of Fraunhofer ISE. This BMS continuously monitors the sensors and has the ability, as a central control unit, to specifically initiate heating of the cell to activate the self-healing functions. This process is in turn subject to the control of a temperature sensor integrated into the cell.

All processes are also being simulated by the research groups in the project. Independently of the sensor readout, a physics-based battery model is integrated into the BMS that replicates the processes and enables degradation processes via the collection of usually available operating data.

The project is rounded off by a comprehensive life cycle assessment. This not only ensures the recyclability of the Salamander batteries, but also assesses the quantitative impact on the environmental impact of the batteries resulting from the lifetime extension under the SALAMANDER project.

SALAMANDER Project – Smart, Self-Healing Batteries for a Sustainable Future