| Duration: | 01/2020 - 12/2022 |

| Contracting Authority/ Sponsors: | Zuwendungsgeber: Bundesministerium für Wirtschaft und Energie (BMWi.IIC6); Projektträger: Forschungszentrum Jülich GmbH (PT-J.ESN4) |

| Project Partners: | Vaillant GmbH |

| Project Focus: |

safeSENSE

Development and Evaluation of an Innovative Safety Feature for Heat Pumps with Natural Refrigerants Based on Sorption Elements and Novel Sensor Technology

Without a doubt, heat pump technology is a key element of the heating transition. In 2015, the F-gas Regulation took effect in order to combat the increasing emissions of (partially) fluorinated hydrocarbons from the cooling circuits built into heat pumps. The regulation envisages the phaseout of harmful, (partially) halogenated refrigerants with a high global warming potential (GWP). Alternative and natural refrigerants with very low GWP are already being used in white goods and in heat pumps installed outdoors. The safeSENSE collaborative project involves developing approaches for the safe use of heat pumps installed indoors.

Alternative and natural refrigerants with very low GWP are often Class A2L or Class A3 refrigerants, which means that they are flammable.

The goal of the collaborative project is to ensure that heat pumps can operate safely throughout their life cycles, thereby improving the market acceptance for the use of heat pumps with natural refrigerants to provide heating and hot water in single- and multi-family homes while also improving the eco-friendliness of heat pump technology.

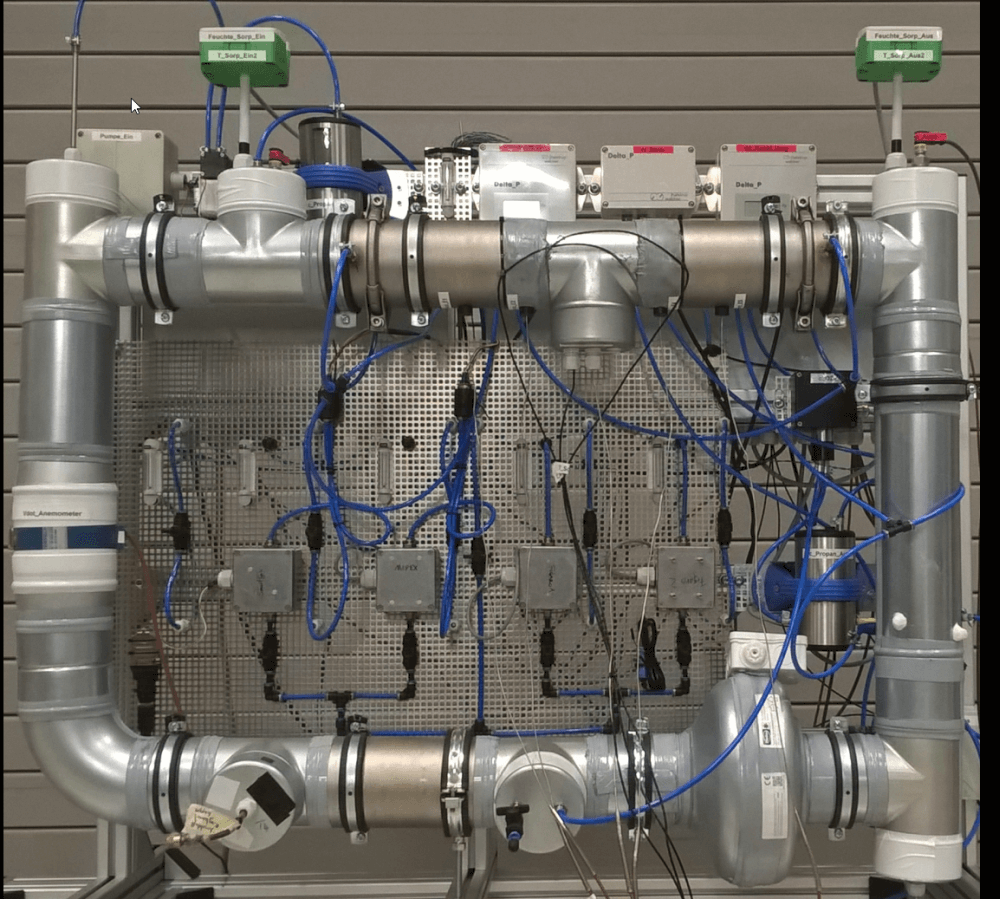

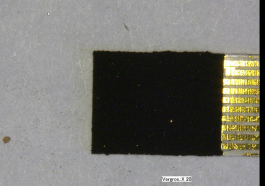

In addition to evaluating various safety devices, the project also aims to develop an innovative thermal sensor based on an adsorbent coated sensor layout in cooperation with Fraunhofer IPM.

- Environmentally Friendly Refrigerants for Heat Pumps (ise.fraunhofer.de)

- Component and Device Development (ise.fraunhofer.de)