| Duration: | 11/2016 - 12/2020 |

| Contracting Authority/ Sponsors: | Bundesministerium für Wirtschaft und Energie (BMWi) |

| Project Focus: |

PV-BAT400 – PV-Basis Technology for Highly Efficient Modules with 400 W Power and Power Density of 240 W/m2

The aim of the project is to develop bifacial silicon solar cells and modules with power densities of pBifa = 240W/m² (irradiance from the front Gfront = 1000W/m², irradiance from the rear side Grear = 100W/m²) on a module surface of at least one square meter. With this power density, a power output of 400W is achieved for today's predominant module size of approx. 1.67m². This is approx. 100W or 33% more than with conventional monofacial top modules in this size class.

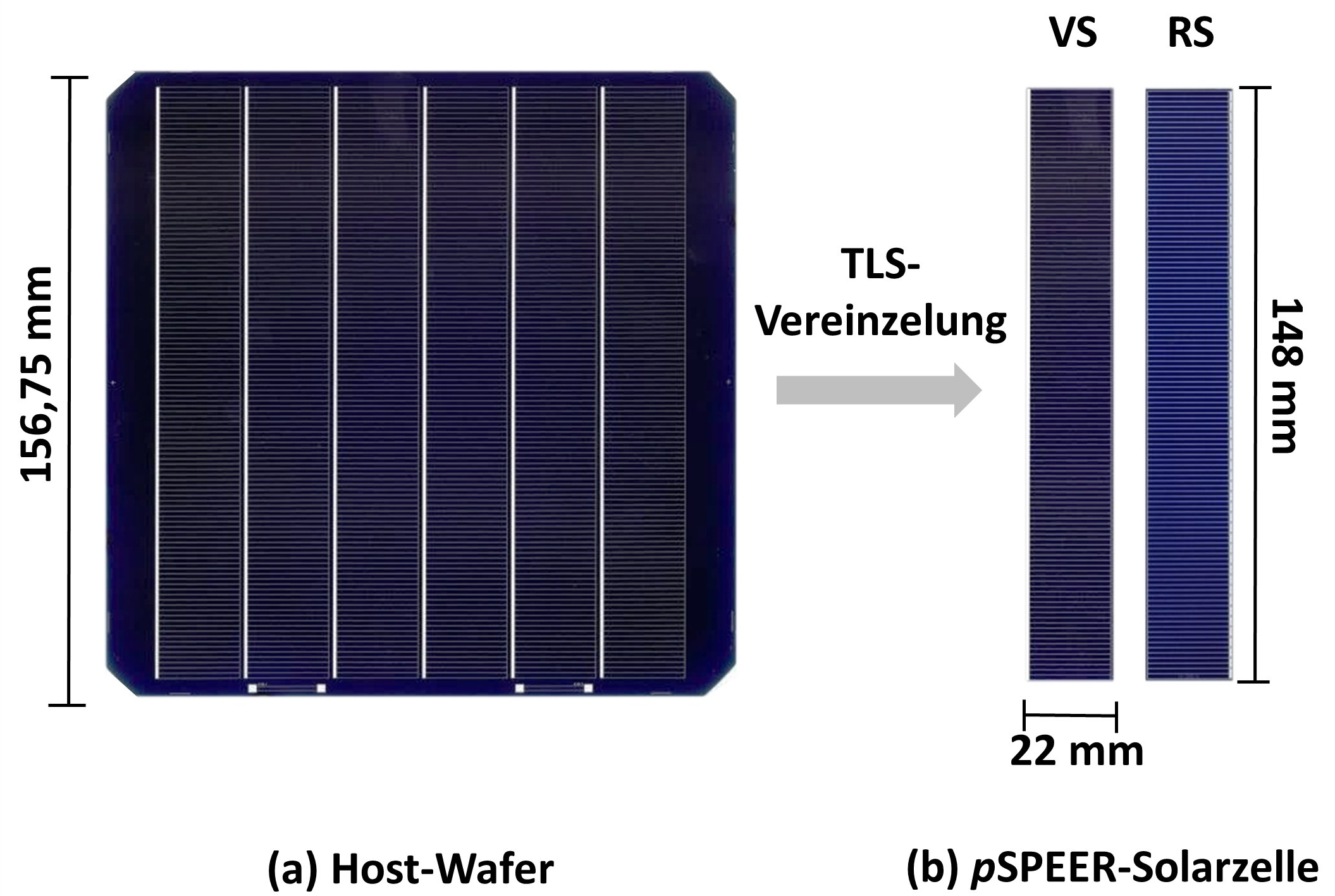

To achieve these performance targets, the use of highly efficient bifacial solar cells with excellent surface passivation is necessary. For this purpose, the "Shingled Passivated Edge, Emitter and Rear (SPEER)" cell architecture with "Passivated Edge Technology (PET)" will be used, in which the cell edges are also passivated. The "Thermal Laser Separation (TLS)" process is to be established and further developed for extremely low-damage separation of the solar cells. For the SPEER shingle solar cells to be developed, a power density of pBifa = 240W/m² is required at cell level, which corresponds to a cell efficiency of about 22.1% with 85% bifaciality.

To further increase solar cell output, the contact surfaces ("Con") are also to be passivated and used as so-called "SPEERCon" technology. Herewith, the goal is to develop SPEERCon solar cells with a power density of pBifa = 260W/m².

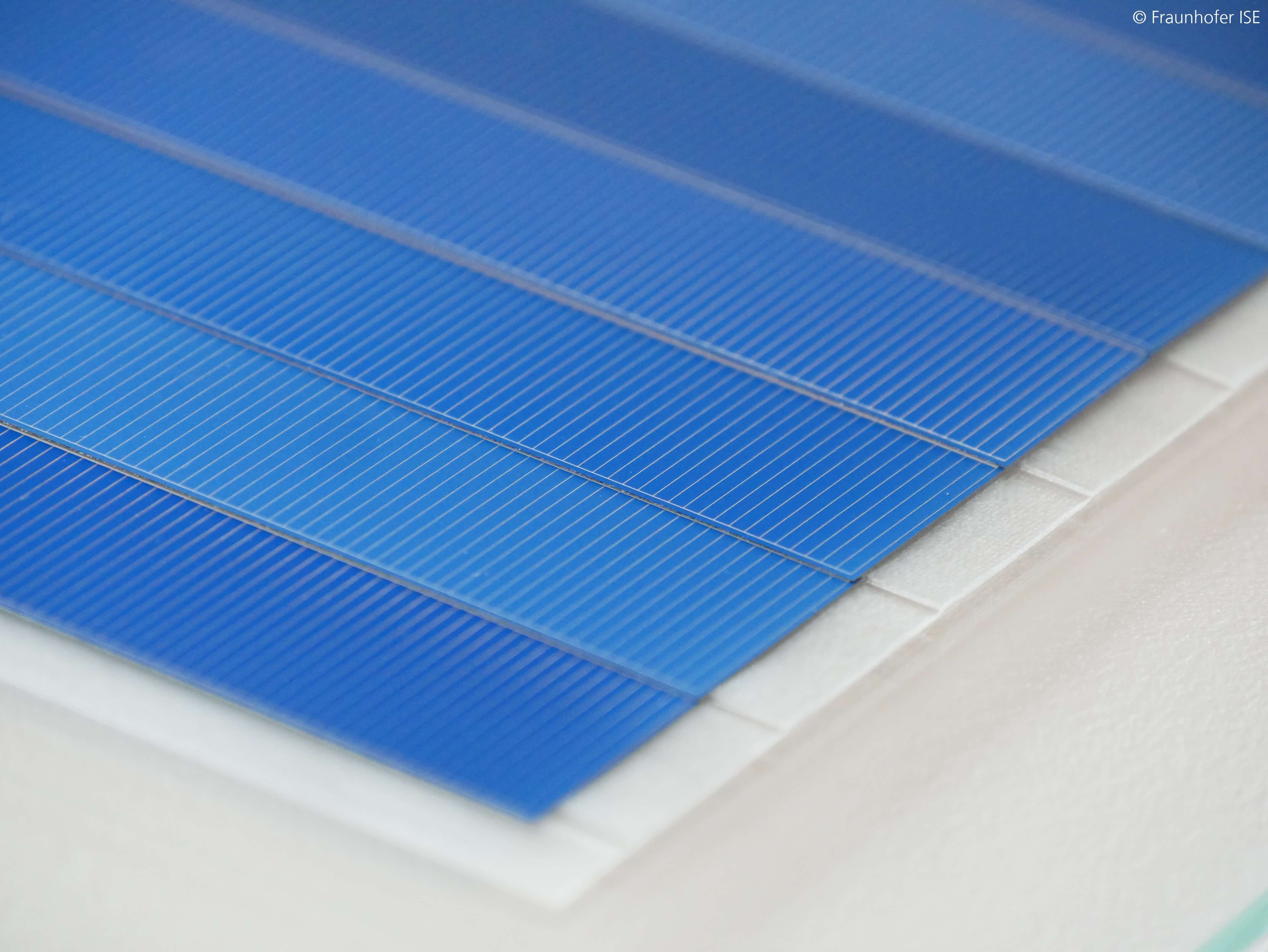

Joining and encapsulation technology aims for outstanding power densities. For highly efficient land use, a new approach to the particularly space-saving interconnection of cell strips is being pursued ("matrix shingles"). This approach avoids inactive module surface almost completely and, in combination with the patented "SlimLine" process, enables an integral production process. As an alternative technology route, an optimized multi-wire approach is used for highly efficient material utilization, combining TopCON half-cells with thin-wire interconnection. Both high-performance module technologies are to pass essential test requirements of IEC 61730/61215.