| Duration: | 10/2018 - 09/2021 |

| Contracting Authority/ Sponsors: |

Bundesministerium für Wirtschaft und Energie (BMWi) |

| Project Partners: | ZAE Bayern |

| Project Focus: | |

PCM Metro II – Dynamic behavior and Aging of PCM Components

Knowledge about the lifetime of a phase change material (PCM) is essential for its technical use. In order to determine the lifetime, the aging mechanisms must first be understood. The established accelerated aging procedures must be modified or/and new methods must be developed. In the PCM-Metro II project, the objective is to create a basis for the development of accelerated aging tests specifically for the PCM material as well as measurement methods to determine the degradation parameters. By comparing the accelerated aging and realtime aging experiments, scaling parameters can be determined, allowing the extrapolation of the accelerated aging results to the actual PCM lifetime.

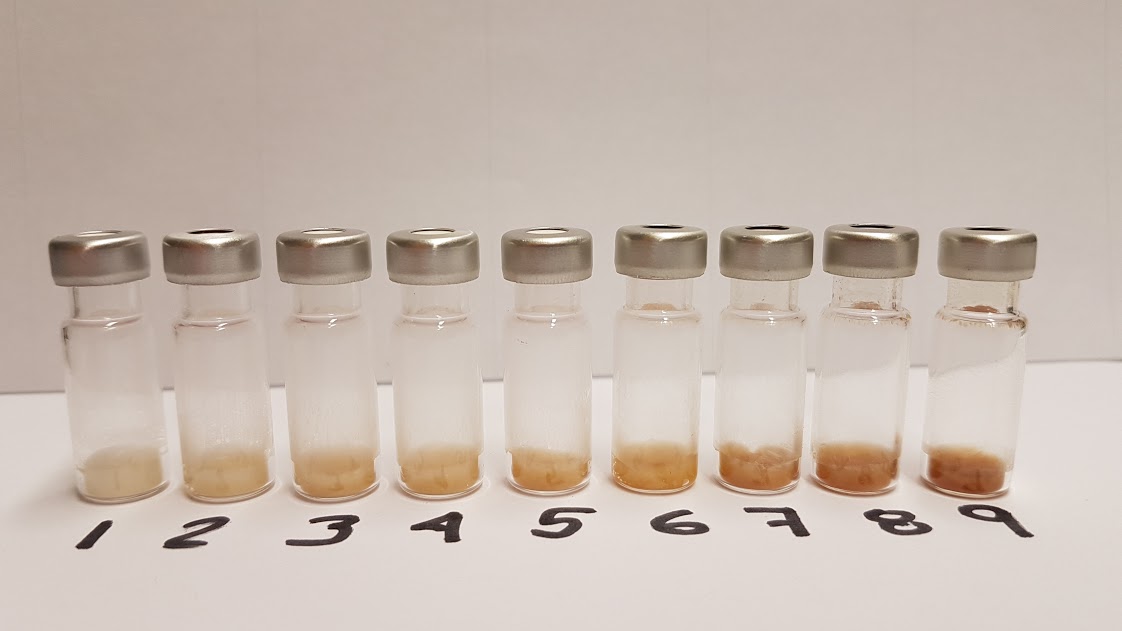

To guarantee the expected lifetime of a PCM in an application, the aging behavior of the PCM must be known. Aging mechanisms can differ for the various PCMs and PCM systems. In order to determine aging under real conditions based on accelerated aging results, the aging mechanisms of the material must be known and the appropriate test procedure must be selected. Up to now, thermal cycling is most often used for PCMs, since PCMs undergo a cyclical sequence of melting and crystallization. The effect of the adjustable cycling parameters (such as heating and cooling rate, temperature limits and the length of the isothermal phases) on the PCM heating and cooling cycles has been little studied so far. In addition, several influencing variables such as segregation and chemical change of the materials can be superimposed on each other during a cycle. Thus, it is possible to determine the probability of damage, but not the causes, which makes material optimization during product development difficult. Since the test methods for PCMs are not standardized, it is difficult to compare the results from different laboratories and also from different materials. Such comparisons can only be used to a limited extent for determining the actual service life in the application.

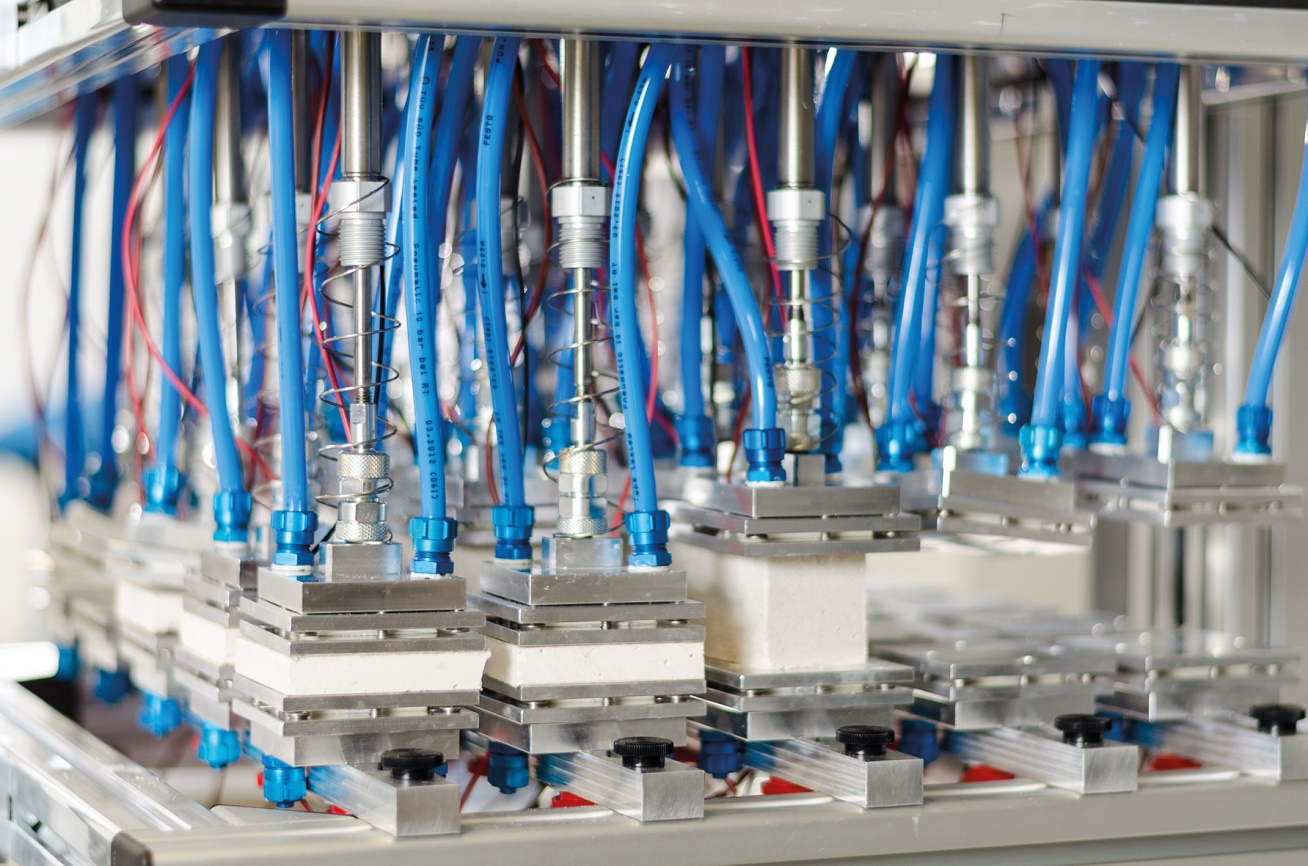

As a rule, pure PCMs can be thermally cycled very quickly. This does not hold for macroscopic systems, such as PCM-filled bags and plates, however, since the cycle time increases sharply with increasing size and complexity. For these systems, standardized test and analysis procedures need to be developed that enable the lifetime of the test specimens to be determined within a comparatively short amount of time.

Therefore, the project aim is to gain a fundamental understanding of the aging processes for the different material classes of PCMs, so that in the future reliable measurement procedures and objective analyses can be made at an early stage. In developing the measurement methods, one focus is on reducing the required measurement time. Processes that significantly accelerate the aging of PCM and PCM systems shall be developed so that reliable assertions about the service life can be made comparatively early. Besides the usual method of thermal characterization used up to now, alternative analysis methods for determining degradation rates and material changes of the PCM at an early stage are being investigated. By comparing the accelerated aging results with real-time aging, scaling parameters will be derived, which allow the test results to be extrapolated to real-time applications. A method matrix is to be developed, in which the material-dependent accelerated aging methods shall be defined, including both the test procedures and the analyses. The results shall serve as a basis for a future standard on the lifetime analyses methods for PCMs.