| Duration: | 10/2022 - 09/2024 |

| Contracting Authority/ Sponsors: | Baden-Württemberg Ministry of Science, Research and Arts (BW(MWK)), European Regional Development Fund (ERDF) |

| Project Focus: | |

PARAMETALLICA – Development of a FlexTrail Parallel Print Head for the Metallization of High-Efficiency Solar Cells

The independent availability of PV electricity in the EU, in Germany and in Baden-Württemberg requires the mapping of all value chains, including the production of solar cells. Innovative solar cells and production processes are key technologies for the re-establishment of solar cell production in Europe.

Perovskite silicon tandem solar cells achieve high efficiencies (> 30%), but also have specific requirements for the manufacturing process. In terms of metallization, these are low silver consumption and low process temperatures, which established processes such as screen printing cannot ideally meet.

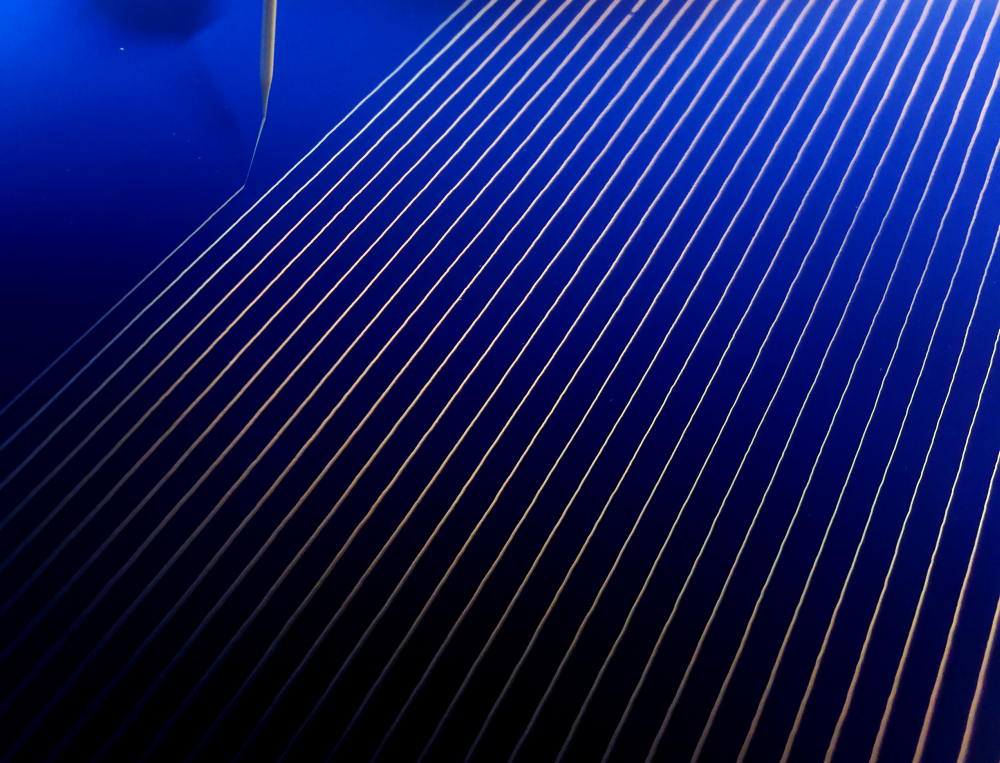

In PARAMETALLICA, the FlexTrail production process developed at Fraunhofer ISE is to be further developed through the development of a parallelized print head (as a prototype), whereby the proof of function is carried out using the perovskite silicon base process in the PV pilot lines of Fraunhofer ISE.

Perovskite silicon tandem solar cells are expected to gain significant market share in the future due to their high potential efficiency gain of more than 3-4%abs compared to the state of the art (PERC, passivated emitter and rear contact). The metallization of perovskite silicon tandem solar cells is a major challenge and innovation lever. Solutions with a high degree of differentiation compared to the usual PV manufacturing processes in China, such as FlexTrail, strengthen the initiatives already available and can contribute to the sustainable re-establishment of PV production in Germany and the EU.

The challenge is the stable deposition of metal at comparatively low process temperatures of less than 140°C, which requires the use of low-temperature pastes or printing media with nano-scale metal particles, which can typically form high electrical conductivities even at low temperatures.

Compared to typical silicon solar cells, tandem solar cells have a lower current density, which favors the design of solar cells with higher series resistances or resource-saving precious metal coatings. With typical metallization processes such as screen printing or dispensing, which are thick-film printing processes, this potential can hardly be exploited. The FlexTrail process, on the other hand, appears to be ideally suited as it has proven itself in the deposition of nano-scale print media and enables the deposition of conductive tracks with sub-micrometer precision.

Simulations show efficiency potentials of 29.2% for FlexTrail-metallized perovskite-silicon tandem solar cells with an Ag consumption of less than 10 mg/solar cell). PERC solar cells with screen-printed metallization, on the other hand, achieve efficiencies of 23% in production with a silver consumption of 75-100 mg/solar cell, which underlines the enormous potential of the approach described.

Finally, machine throughputs of 7,000 wafers/h (today) and over 10,000 wafers/h in the coming decade are expected in PV production. With a traversing speed of 500 mm/s, the FlexTrail process has the potential to map corresponding throughputs in a single production system, although the parallelization of FlexTrail print heads - the central goal of PARAMETALLICA - is required.