| Duration: | 6/2019 - 5/2022 |

| Contracting Authority/ Sponsors: | Bundesministerium für Wirtschaft und Energie (BMWi) |

| Project Partners: | ARMOR solar power films (ASPF); endiio Engineering GmbH; Universität Freiburg |

| Project Focus: |

ORGANAUT – Organic Photovoltaics for Autonomous Linked Sensors and Internet of Things

Due to their typically larger band gap, organic solar cells are ideally suited for indoor applications with the lighting conditions prevailing there. For example, spectra of fluorescent lamps or LEDs at 500 lux allow theoretical efficiencies of up to >55% for band gaps of the absorbers in the range of about 1.9 eV.

In order to exploit this high potential at low light intensities, however, the solar cells must have extremely high parallel resistances, because otherwise significant voltage losses occur. To ensure this, an electrode system developed at Fraunhofer ISE and the University of Freiburg (patent pending) is used. This has already enabled us to achieve promising efficiencies of around 20%.

In the joint project "ORGANAUT" funded by the Federal Ministry of Economic Affairs and Energy (BMWi), we are developing organic solar cells and modules for use under lighting conditions such as those prevailing indoors. We want to use it to supply sensors and wireless data loggers with electrical energy.

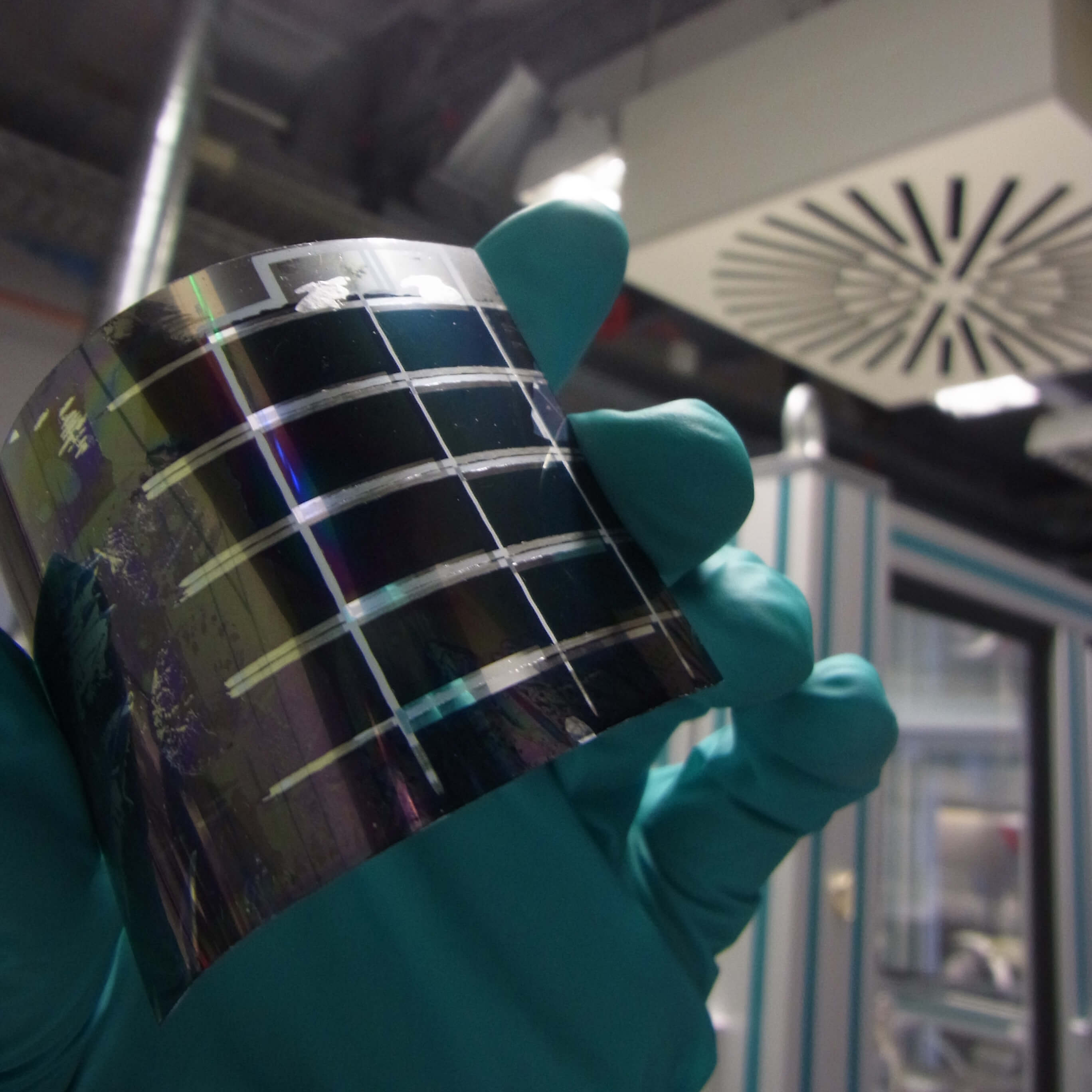

For this purpose, we are developing flexible organic solar modules based on cost-effective electrodes. In this way we want to save costs while avoiding local short circuits. Due to the low light intensities (mostly 100-500lux), the latter is essential to achieve high efficiencies. Our electrode development aims to achieve a high tolerance of coating defects. This is first investigated on small areas using solar cells before the processes are then transferred to our roll-to-roll coating line at the module level. The cells and modules undergo various tests for accelerated ageing, e.g. at elevated temperatures. This is accompanied by work on characterization and modeling, which takes place at the University of Freiburg, among others. The aim is to identify the factors limiting the efficiency as precisely as possible and to evaluate the optimization potential. The knowledge gained in this way will be used in further experiments to optimize the cell stack and module layout.

The material combinations and parameters determined in this way are then transferred to the industrial partner ASPF, where the organic solar modules of various shapes and sizes are manufactured. The company endiio will then supply its sensor systems with radio data logger and intelligent charging electronics with the electrical energy from the organic solar modules and test the systems under real industrial operating conditions.