| Duration: | Mai 2015 - Februar 2019 |

| Contracting Authority/ Sponsors: | Federal Ministry of Education and Research (BMBF) |

| Project Partners: | FläktGroup Deutschland, AK Janiak / Heinrich-Heine Universität Düsseldorf |

| Project Focus: |

OPTIMAT – Optimization of Innovative Materials for Cyclic Adsorption Processes

Heating, cooling, humidification and dehumidification - these processes account for more than 40 percent of Germany's primary energy consumption. The aim of the project is to develop a functional pattern for direct dehumidification of supply air in buildings using porous, sponge-like materials. Instead of using electricity, the often abundantly available and more energy-efficient waste heat or district heat can be used for air conditioning. In addition to the synthesis and characterization of new high-performance materials, the shaping of these materials and flow-optimized heat transfer structures play an important role. These fundamental research works are finally brought together in a functional pattern which is used to demonstrate the efficiency of this technology.

With increasing prosperity, the need for air conditioning increases. At the same time, the available quantity of climate-damaging refrigerants, so-called F-gases, which are required for the operation of conventional air conditioning units, is massively reduced. In cooperation with researchers from the Heinrich Heine University Düsseldorf and the specialists for venilation and air conditioning from FläktGroup, the potential of sorption-supported air conditioning is evaluated in OPTIMAT. In this process, a water-attracting, porous material, the adsorbent, is used to extract humidity from the outside air. As soon as the absorption capacity of the adsorbent is exhausted, the water is expelled with waste heat or district heat, for example. Thus, the adsorbent is available dry again and the cycle is closed.

In a basic part, new adsorbents are synthesized and evaluated from the classes of metal-organic frameworks (MOFs) and covalent organic frameworks (COFs). Not only a suitable characteristic of water adsorption is important, but also stability over the entire life cycle.

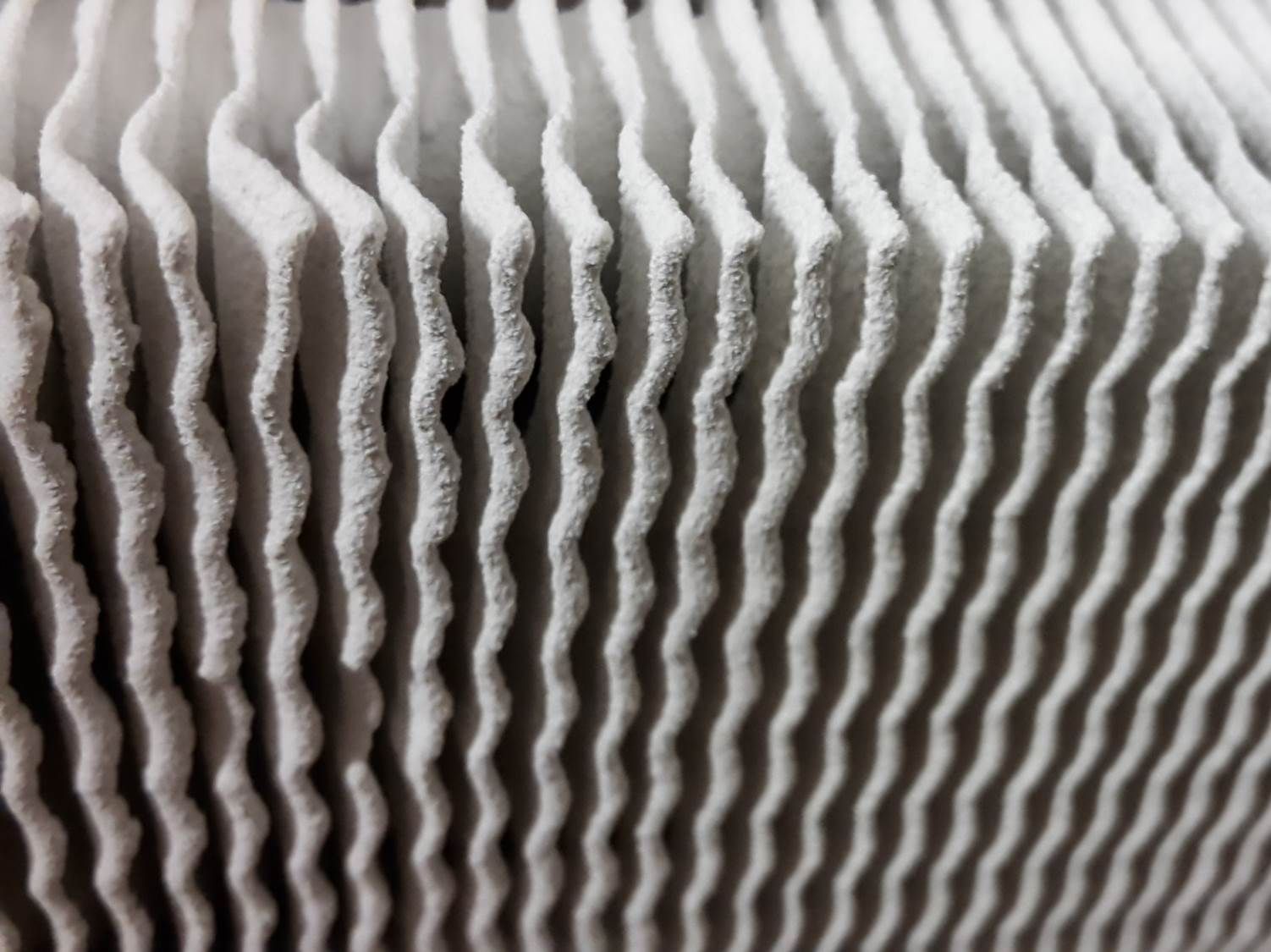

The shape of the adsorbent is also decisive for its performance. Here, approaches are being taken to grow the adsorbent directly on a heat-conducting structure or to embed it in a polymer matrix. In addition, various processes such as dip and spray coatings are being evaluated, with which the adsorbent is applied to a structure using a binder.

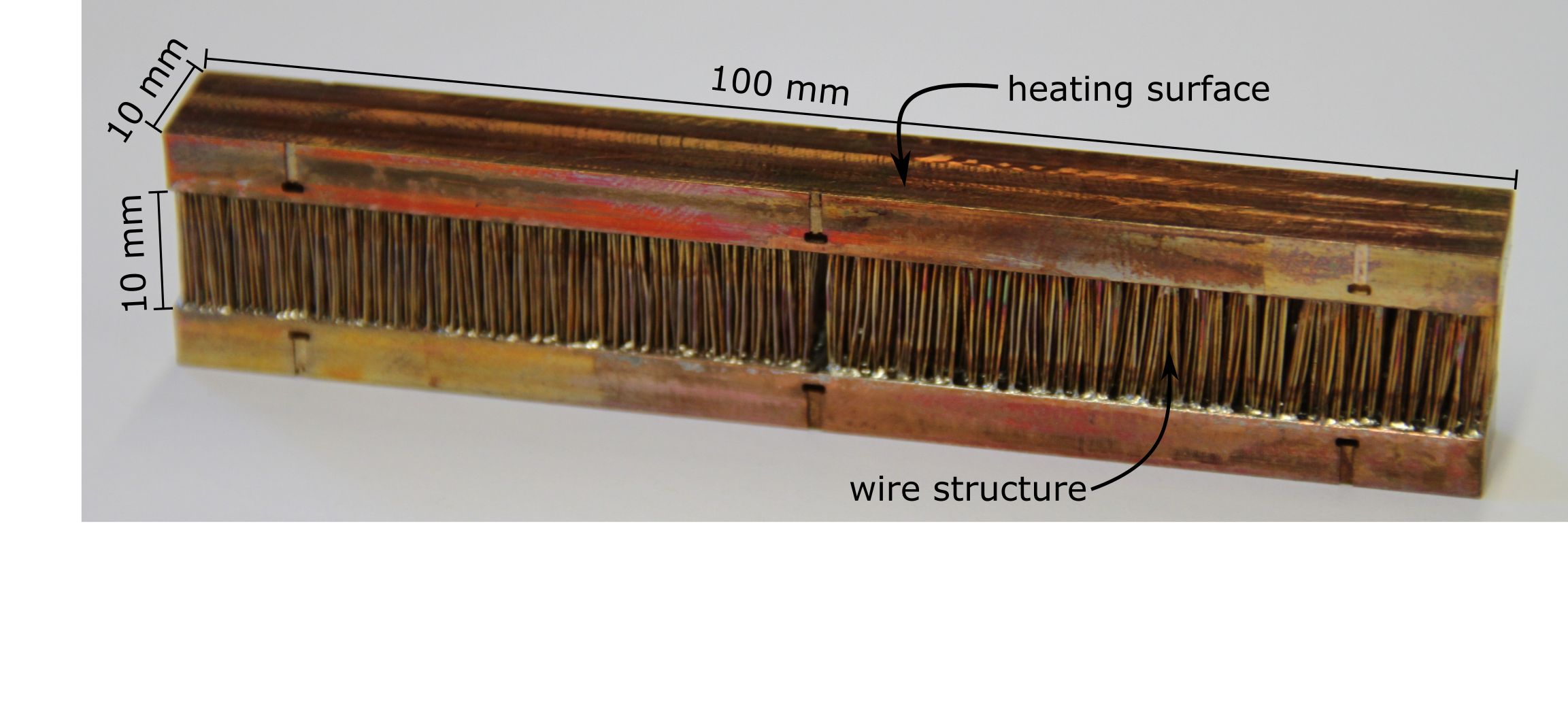

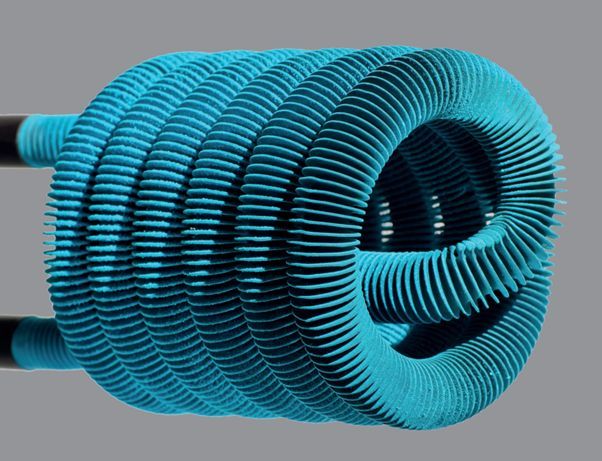

The adaptation of heat exchanger structures to the requirements of flow geometry and heat transfer offers further potential for increasing efficiency. Wire structures can be produced using textile manufacturing methods; embedded in a heat exchanger, these can enable significantly better heat transfer and large surfaces with a more compact design.

The results of this basic research part of the project will be brought together in a second, application-oriented half of the project. Part of this project phase is the scaling up of the investigated processes (e.g. synthesis and coating) as well as the production and measurement of wire structure heat exchangers. The work will be flanked by a model simulation and brought together in a demonstration pattern.