| Duration: | January 2012 – December 2014 |

| Contracting Authority/ Sponsors: | German Federal Ministry of Economics and Technology (BMWi) |

| Project Partners: | Solvis GmbH u. Co. KG, Herrmann GmbH u. Co. KG, Elster GmbH, Umicore AG u. Co. KG |

Oil Vapour Burner – New Evaporation Process – Clean Future for Oil Heating

The primary energy demand to supply energy to buildings is sinking due both to improved thermal insulation and also to increasing application of solar thermal systems or ventilation systems with heat recovery. The lower heating demand is stimulating the demand for modulating heating systems which can meet the constantly high power demand for domestic hot water and the low power demand to provide heat for space heating. However, the construction principle of conventional oil-fuelled burners means that they cannot be modulated. Thus, we have cooperated with the industrial partners, Herrmann GmbH & Co. KG, Solvis GmbH & Co. KG, Elster GmbH and Umicore AG & Co. KG to develop an oil vapour burner which features efficient combustion, can be modulated and simultaneously reduces emissions.

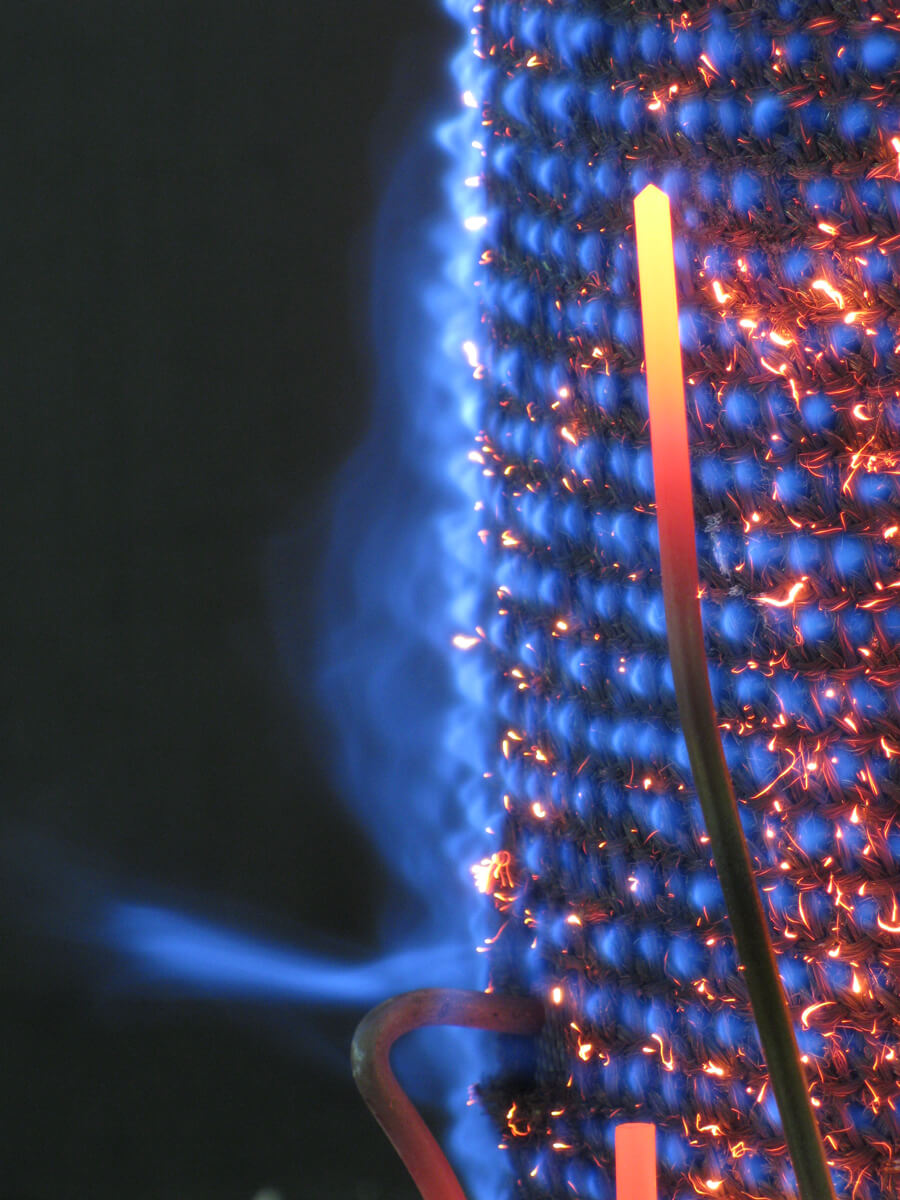

The core of the oil vapour burner is a catalytic process developed at Fraunhofer ISE, which can evaporate heating oil and other liquid hydrocarbons without any residues. When the fuel is evaporated, an appreciably better mixture with air for combustion can be prepared. Formation of this mixture is a decisive criterion for the combustion quality. Poor mixing leads to higher emissions of nitrogen oxides, carbon monoxide, hydrocarbons and soot. The evaporator unit is integrated simply before the burner. With this unit, heating oil can burn in gas burners efficiently and with low emissions. In addition, the existing, cost-effective system configuration from gas combustion can now also be used for oil.

Initial investigations at Fraunhofer ISE on gas burners from Solvis and Herrmann demonstrated that the emission values over the complete modulation range from 5 to 15 kW thermal power lie below the prescribed limits. The wide modulation range contributes to this effect, as the number of starts for the burner is reduced considerably. Furthermore, the emission of nitrogen oxides is reduced compared to conventional oil burners. The burner operation complies with both the DIN EN 267 standard and the first German emission control ordinance. The oil vapour burner is also suited for use in living rooms, as it is quieter than a normal oil burner.