| Duration: | September 2012 - September 2016 |

| Contracting Authority/ Sponsors: | Fuel Cell and Hydrogen Joint Undertaking of the European Commission |

| Project Partners: | Stifelsen SINTEF, Norway; Commissariat a l'Energie Atomique et aux Energies Alternatives, France; Areva H2Gen, France; Johnson Matthey Fuel Cells Ltd., Great Britain; Teer Coatings Ltd., Great Britain; Paul Scherrer Institute (PSI), Switzerland |

| Website: | www.novelhydrogen.eu/ |

| Project Focus: |

Novel – Characterization of High-Pressure Stacks

Using renewable electricity, "green" hydrogen is generated in a Proton Exchange Membrane (PEM) electrolyzer by means of water electrolysis. Hydrogen can be used as storable secondary energy carrier in many applications. The objective of the “NOVEL” project is the development of novel, efficient, and cost-optimized cell components for the electrolysis cell stack and for testing suitable test procedures for the investigation of durability and the derivation of accelerated aging tests. In the case of successful project completion, a prototype stack should produce hydrogen with an efficiency > 85 % (HHV) and a degradation rate < 15 µV/h. Specific stack costs < 2000 € / (Nm³ h-1 H2) should be achieved.

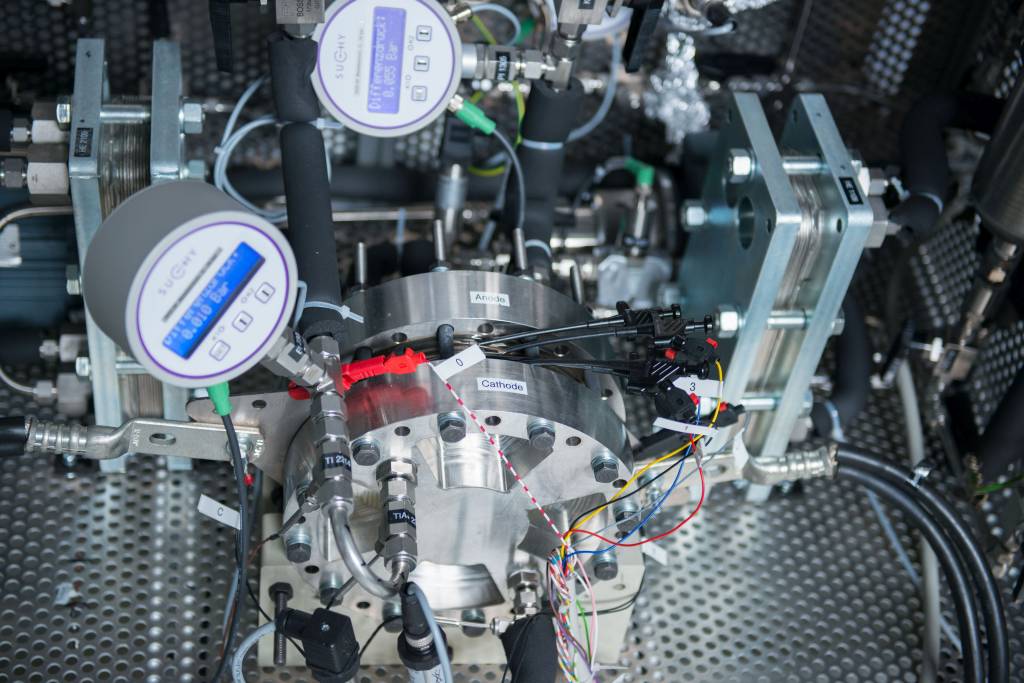

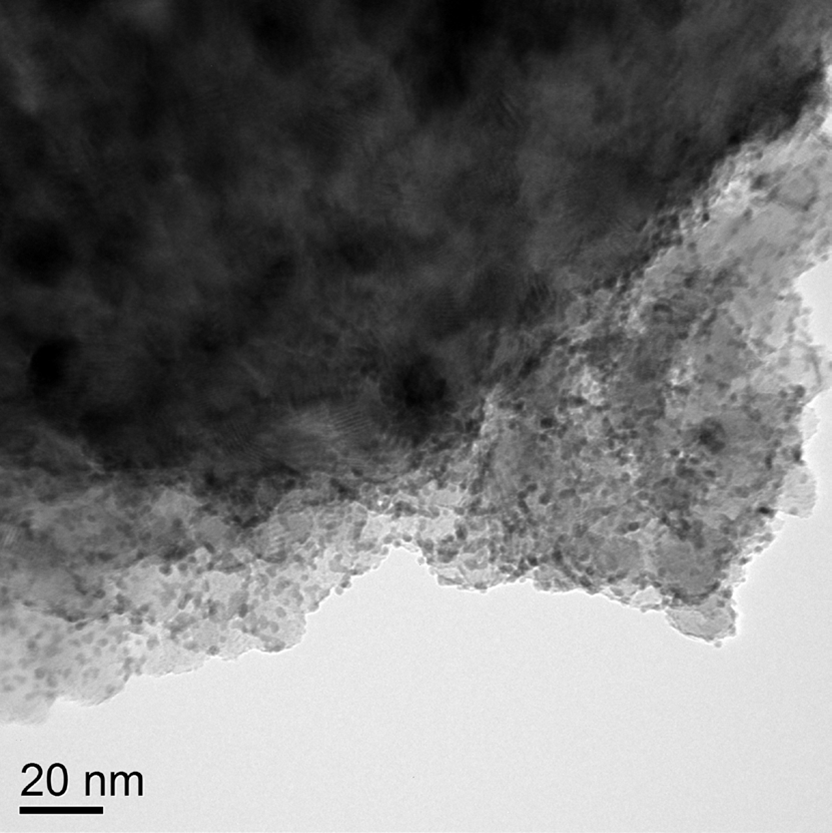

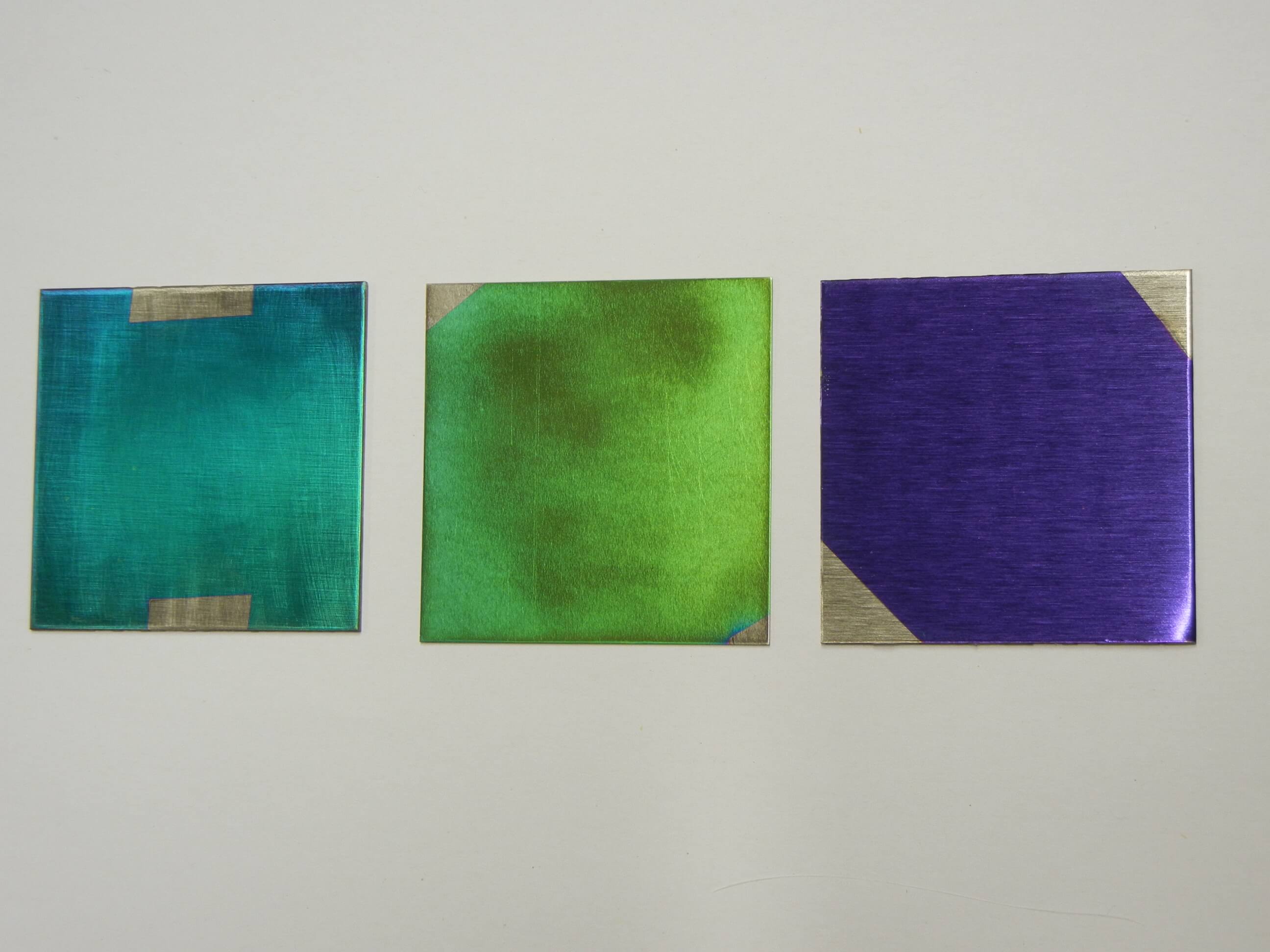

Fraunhofer ISE collaborates in the “NOVEL” project with European partners from industry and research of five different countries in the improvement of materials and components for PEM electrolysis. Among others, alternative membranes are synthesized, featuring less hydrogen and oxygen permeation, increased mechanical stability, and increased ionic conductivity compared to the currently used standard material. With radiation grafted and sulfonated membranes on ETFE basis show promising results. In a further step, these membranes are coated with new catalyst materials for the anode, which shows higher catalytic activity and a reduced precious metal content. For this purpose, different production and coating methods of iridium-based catalysts on niobium and/or tantalum-doped titanium oxide carriers are investigated. To improve the stability of titanium components, corrosion-resistant protective layers are developed that mainly should prevent the formation of high-impedance passivation layers. The newly developed materials are investigated in existing test cells in standard characterization and long-term procedures. The interaction of different degradation effects is investigated. Furthermore, Fraunhofer ISE optimizes an existing stack design so that the developed components can be used cost-effectively and efficiently at pressures up to 50 bar(g).