| Duration: | 05/2017 - 04/2021 |

| Contracting Authority/ Sponsors: | Zuwendungsgeber: Bundesministerium für Wirtschaft und Energie (BMWi.IIC6); Projektträger: Forschungszentrum Jülich GmbH (PT-J.ESN4) |

| Project Partners: | Stiebel Eltron GmbH & Co. KG, Holzminden |

| Projektfokus: | |

LowEx-Bestand NK4HTWP – New refrigerants for high-temperature heat pumps

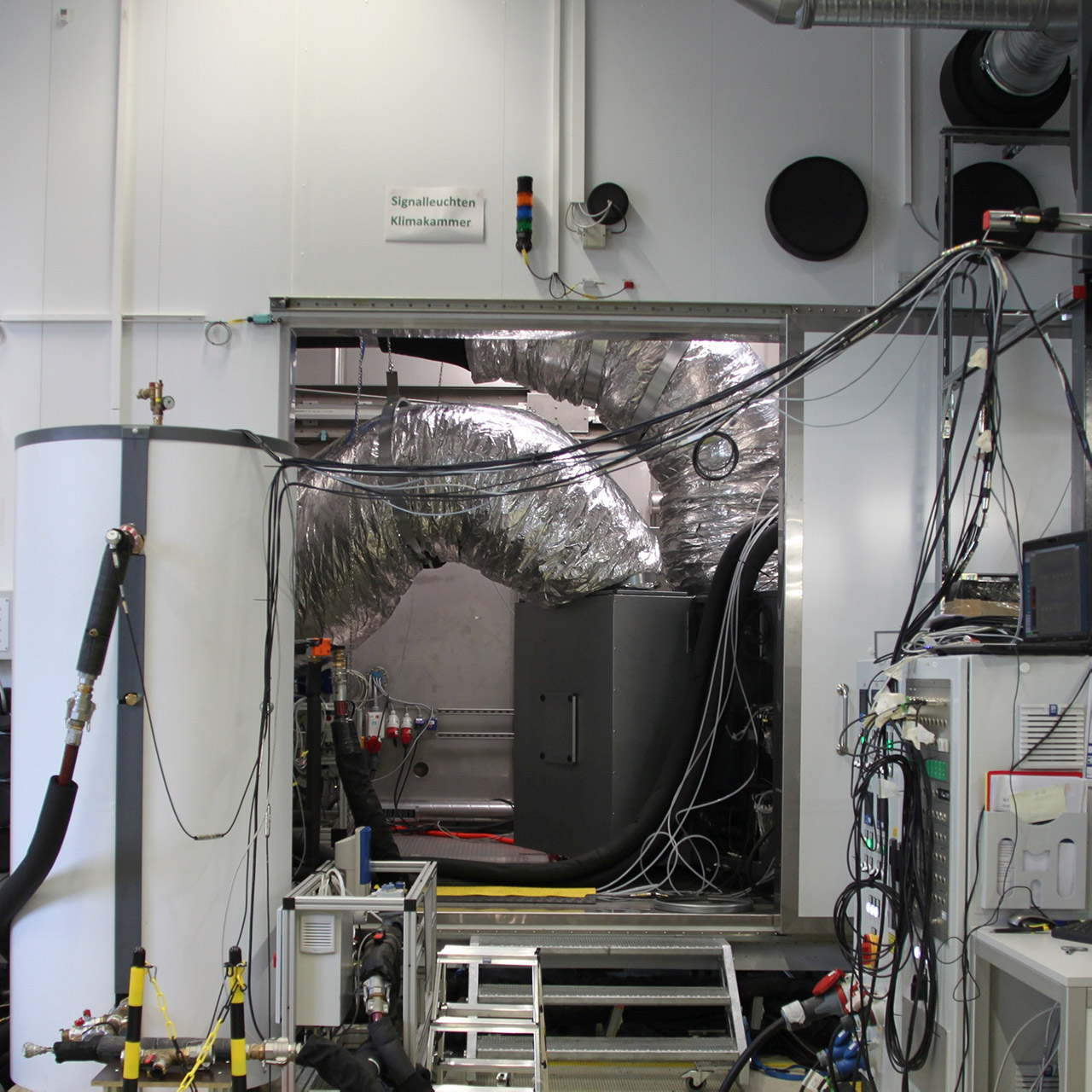

In the "NK4HTWP" research project, a demonstration heat pump is being built that will operate with a new generation of refrigerants with no OPD and low GWP. In apartment buildings, it will provide heating and hot water with a hot water temperature of 60°C behind the hot water storage. Low noise emissions from the unit, high efficiency in heating and providing hot water, and high robustness of the unit are goals of the project

Currently, heat pumps for high flow temperatures are operated with refrigerants that have already no ODP, but still contain a high GWP. The refrigerants used are R410A, but mostly R134a, which is well suited for such heat pumps due to its high critical temperature.A viable replacement candidate for the new generation of refrigerants is R455A with a GWP of 148. This refrigerant has existed asa newly approved blend since 2015. There is virtually no approved components for building such systems on the market.

The aim of the project is to design, build and test a compact and efficient demonstrator of a heat pump generation system that complies with the criteria of DVGW W 551 for large-scale systems with maximum use of the heat pump in monovalent operation. In the project, measures are primarily carried out for the refrigeration and control engineering system development of a suitable heat pump. In terms of refrigeration, the focus is on testing measures for heat extraction (e.g. desuperheaters, massive subcooling) as well as testing a suitable compressor at non-standard operating conditions so that efficiency and service life are guaranteed for a high-temperature heat pump. This work will be combined with vibration engineering studies to achieve both low construction volumes as well as low noise during operation. In addition, the project includes studies to assess the increase in efficiency for this system through the application of appropriate combinations of compressor capacity control, as well as a suitability study of fan coils in place of conventional heat distribution systems.