| Duration: | January 2015 - December 2018 |

| Contracting Authority/ Sponsors: | European Union within the scope of Horizon 2020 |

| Project Partners: | Ayesa Advanced Technologies SA, Powertech Systems, Wind Inertia Technologies SL, Schneider Electric GmbH, Steinbeis Innovation gGmbH, and others |

| Project Focus: |

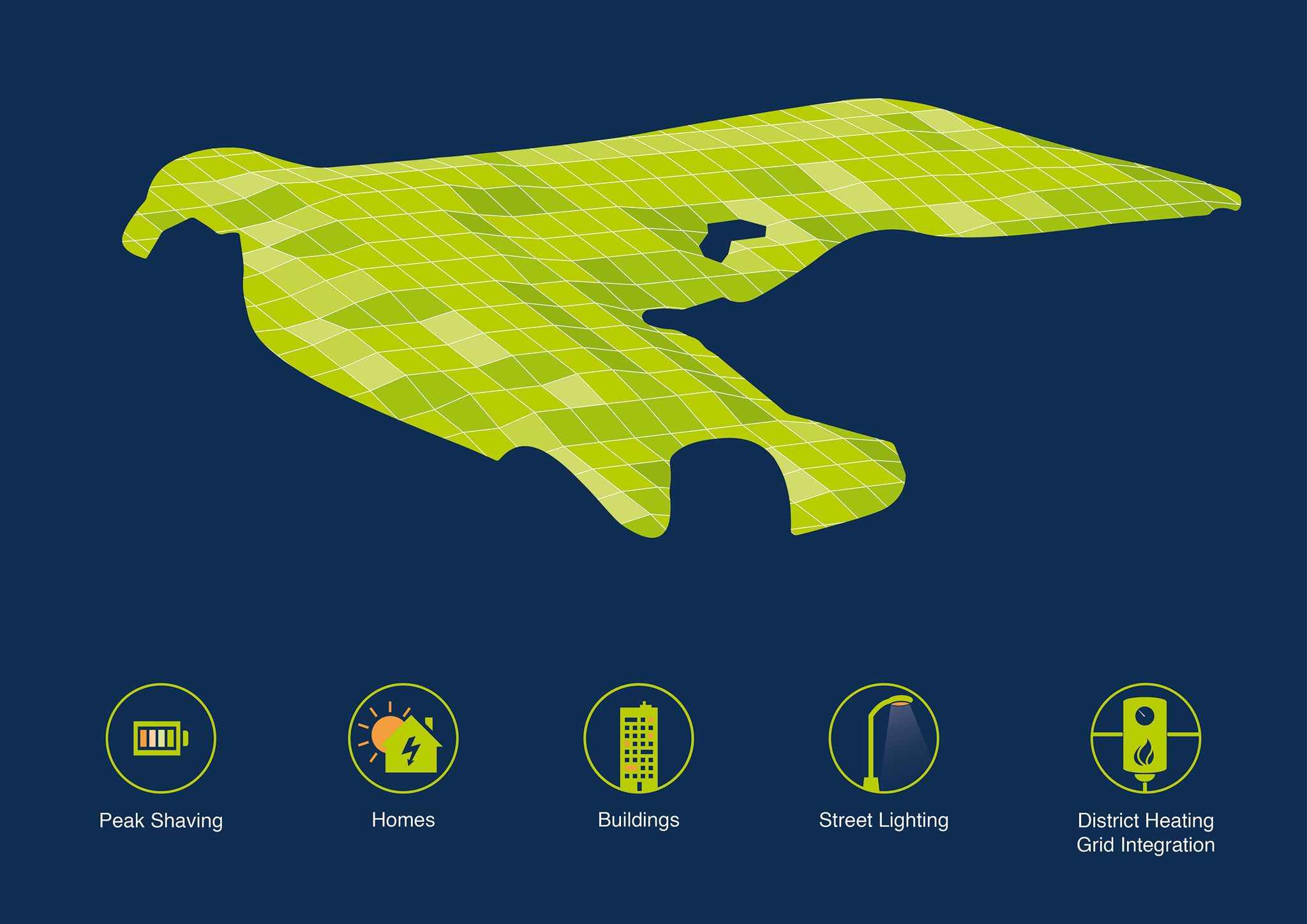

NETfficient – Energy and Economic Efficiency for Smart Communities through Integrated Multi Storage Technologies

Within the scope of the Horizon 2020 project “NETfficient”, the power distribution grid on the North Sea island of Borkum is equipped with a high proportion of renewable energies and diverse storage technologies. Storage solutions are further advanced, integrated into a smart grid, and controlled by an intelligent energy and grid management system. In addition to diverse distributed storage devices, a hybrid energy storage is integrated into the medium voltage grid. The storage with an output of one megawatt consists of a Lithium ion battery with 500 kWh and a highly compact battery inverter developed by Fraunhofer ISE. In addition, a short-term storage device in Supercap technology is integrated via a DC/DC converter in order to cover power peaks and thus extend the service life of the battery.

Thanks to is significantly higher switching frequency, the inverter developed by Fraunhofer ISE can react to fluctuations in the power grid faster than commercially available devices and is thus suitable for use as very fast primary reserve (instantaneous reserve) and for self-consumption solutions on an industrial scale. The megawatt inverter was realized in a 19-inch rack with a height of 200 mm and is thus by a factor of 2 to 4 smaller than currently available reference devices.

The device features a modular design with eight inverter racks with an output of 125 kW each. DC fuses, power stack, output filter, as well as DC and AC contactors are located in the racks. Thus, every rack can be independently disconnected from the overall system. The used snap-in technology of the racks simplifies system maintenance significantly.

300-A silicon carbide MOSFET modules were selected as power semiconductors. Based on the fast switching edges, a low-inductance link had to be introduced based on a high-current board and metal layer capacitors. The power semiconductors are mounted on a liquid cooling element. Water cooling enables easier system adjustment to extreme usage conditions, such as high temperatures or elevations.

A “predictive control” is used for controlling the power electronics. Based on the observation of all relevant currents and voltages in the system and model-based prediction of future states, significant performance gains can be achieved compared to current controllers currently used.