| Duration: | 08/2016 - 06/2020 |

| Contracting Authority/ Sponsors: |

Bundesministerium für Wirtschaft und Energie (BMWi) |

| Project Partners: | Sinusstrom GmbH; LTI ReEnergy GmbH |

| Project Focus: |

MODUS - Modular and Failure-Tolerant PV Inverters for PID-Friendly 1500-V-System Technology

The transition from 1000- to 1500-V systems has led to a significant reduction in investment costs in large PV systems. However, the maximum open-circuit voltage of the PV modules remains the limiting factor in the current park design. Typical DC operating voltages are 900 to 1300 V. In the "MODUS" project, a concept is being developed that enables operating voltages of up to 1500 V. The system concept as well as the modular structure of the central inverter demonstrator developed in the project are designed in such a way that effort and costs can be significantly reduced, especially for small and medium-sized enterprises (SMEs).

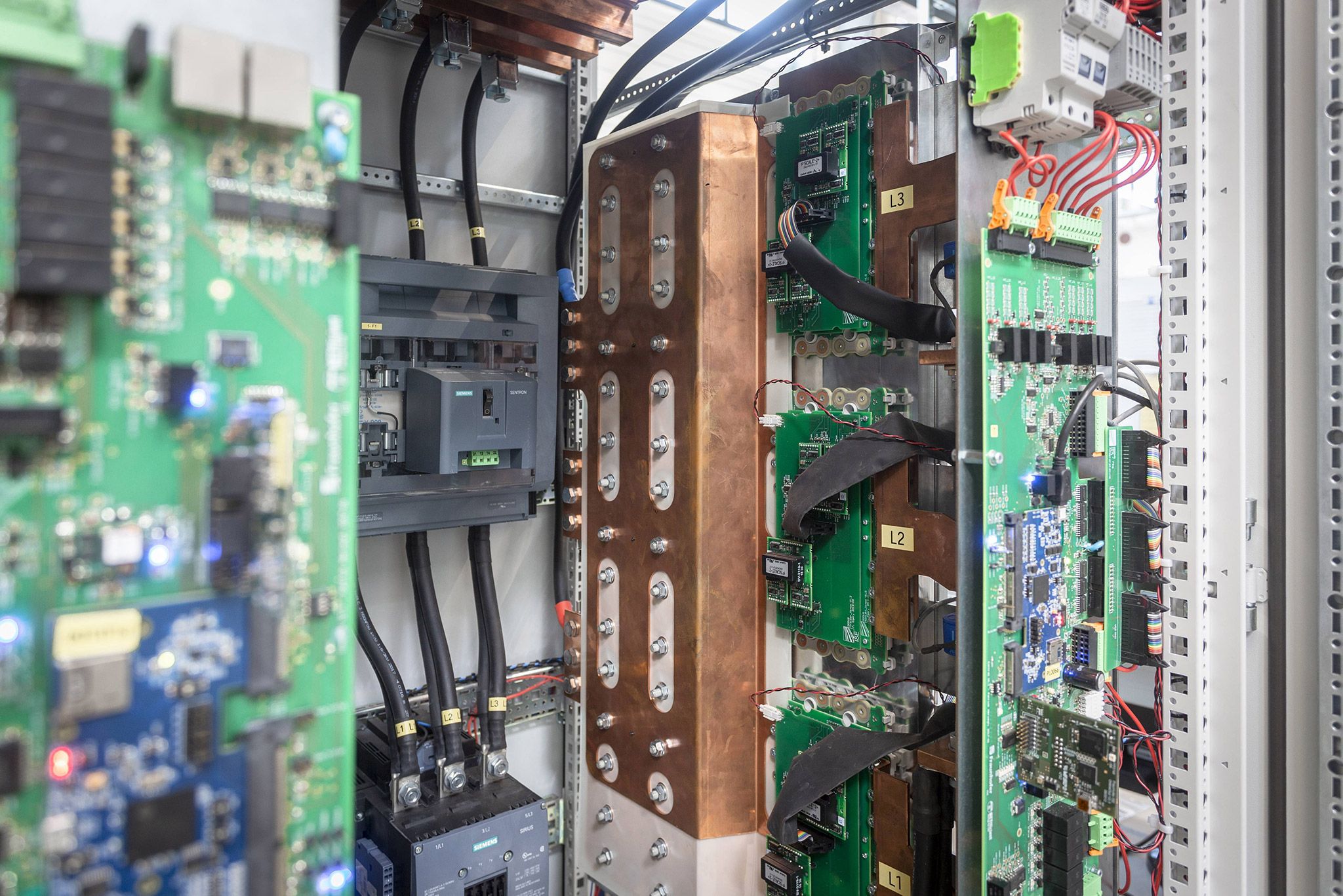

Within the research project "MODUS", a concept for the modular design of a central inverter is being developed and implemented which, with a high number of common parts, allows cost savings in storage as well as in purchasing. In addition, it enables partially automated production without large investments in product-specific production lines. This is particularly advantageous for small and medium-sized companies in order to be able to compete with large companies on the global market. The mechanical parts are designed to be manufactured using simple bending and stamping techniques. This enables the integration of local suppliers close to the installation site of the PV generator.

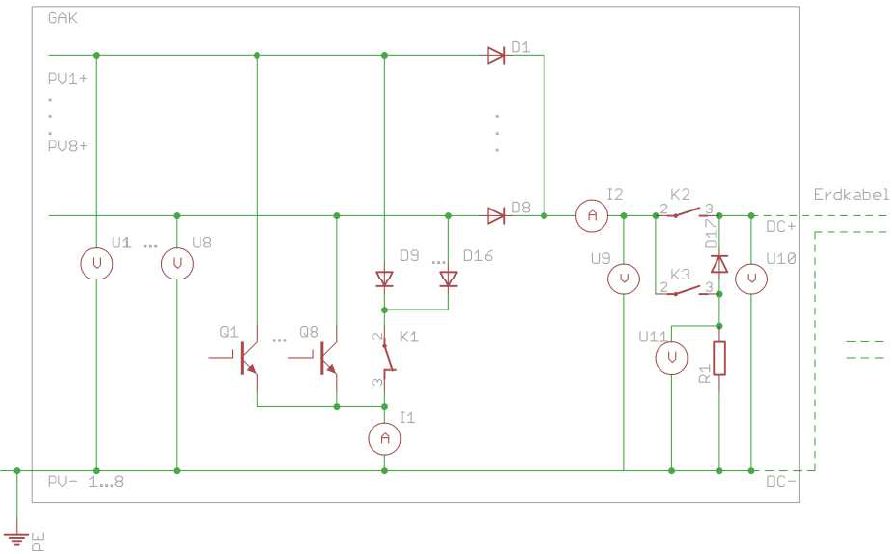

Furthermore, including the switching functionalities of an intelligent string collector (iGAK), a concept is being developed which, by raising the DC open-circuit voltage to 1800 V, allows the operating voltages to be increased from the current approx. 900 to 1300 V to up to 1500 V. This allows the output power of the inverters to be increased by approx. 20%. For large PV parks, the number of inverters required can thus be reduced. In addition, the power-specific cable length required on the DC side is reduced by about 12%. The use of PV negative grounding, which was investigated in the project, leads to a further reduction in cable length of about 30%. The grounding reliably prevents potential-induced degradation (PID) on the PV modules even at increased DC voltage, and no further devices are required for potential boosting.

Thanks to the measurement technology installed within the iGAK, it can be integrated into the plant safety concept for handling ground faults and short circuits and allows improved fault localization. The higher costs for the necessary semiconductor components are offset by the significantly cheaper mechanical switches, which can disconnect without power, so that manufacturing costs for the iGAK can be expected to be comparable with conventional GAK.

However, it must be taken into account that, according to the current IEC standard, string collectors must not exceed open-circuit voltages of 1650 V. In Germany, they are even limited to 1500 V due to a definition in VDE 0100-712. The advantages of the developed solution concept can therefore only be fully exploited if they are taken into account in the standardization.