| Duration: | 10/2018 - 09/2022 |

| Contracting Authority/ Sponsors: |

Bundesministerium für Wirtschaft und Energie (BMWi) |

| Project Partners: | ZAE Bayern |

| Project Focus: |

MINAKRIP – Nucleation and crystallization of microencapsulated and nanoemulsified PCM

The use of Phase Change Materials (PCM) is a promising approach for storing heat in small temperature intervals. However, PCMs often show a sub-cooling effect, which means that these materials have to be cooled much lower than the melting temperature to release the heat stored in the melting process. This effect reduces the storage density and cost-effectiveness of PCMs compared to conventional sensible heat storage. Therefore, it is essential to have a deep and fundamental understanding of the sub-cooling and nucleation processes in these materials, in order to develop efficient PCM storage systems and use this technology cost-effectively in applications.

During the development and use of phase change materials, sub-cooling occurs time and again. Sub-cooling means that molten PCM does not crystallize at the phase change temperature, but rather remains initially liquid. This sub-cooled state is metastable. During further cooling, nucleation occurs at the so-called nucleation temperature and crystallization of the sub-cooled melt is initiated. In most applications, this effect leads to a significant increase in the temperature difference during the process and often to the uselessness of the material, since the required nucleation temperature is not reached in the application. Sub-cooling and the associated large temperature difference between melting and nucleation of the PCM material reduces the storage density of the PCM compared to sensible storage media and also its economic efficiency. Therefore, the sub-cooling effect is one of the main obstacles standing in the way of a wider use of PCMs.

Organic PCMs generally show a low tendency for sub-cooling, although it does occur on a large scale when the PCM is microencapsulated or emulsified. The search for effective nucleating agents is still a purely empirical process for the most part. Here both chance and the experience of the researcher play a role, making it a very time-consuming process.

The project aim is to gain a better understanding of the nucleation processes in microencapsulated and emulsified PCMs in order to be able to select possible nucleating agents in a targeted manner in the future, thus accelerating development processes and increasing the applicability and cost-effectiveness of PCM technology.

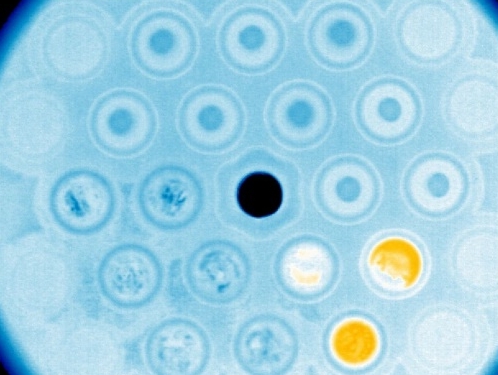

The project investigates the crystallization behavior of paraffins with higher melting points, long-chain alcohols and fatty acids. For this purpose these materials are emulsified or microencapsulated. The crystallization behavior is investigated using caloric methods and X-ray diffraction. The aim is to obtain information about phase transitions and crystal formation when using different seed materials.

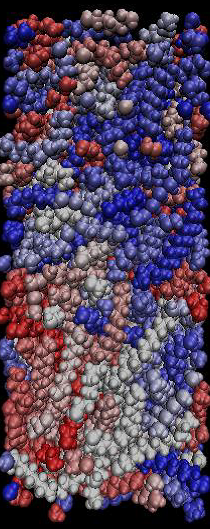

Furthermore, molecular dynamic simulations are used to analyze the interaction between the seed-crystals and PCM on a molecular level.