| Duration: | September 2012 - August 2016 |

| Contracting Authority / Sponsors: | Federal Ministry for Education and Reserach (BMBF) |

| Project Partners: | ZAE Bayern |

| Project Focus: |

MIKOPUK – Supercooling in Microencapsuled Organic PCM

One of the challenges of using phase change materials (PCM) frequently is the super-cooling effect that prevents a wider use of this promising technology. Within the scope of the “MIKOPUK” project, the super-cooling behavior of organic PCM is systematically investigated. The objective is a basic understanding of the mechanism of super-cooling and nucleation, in particular in micro-encapsulated PCM and PCM emulsions.

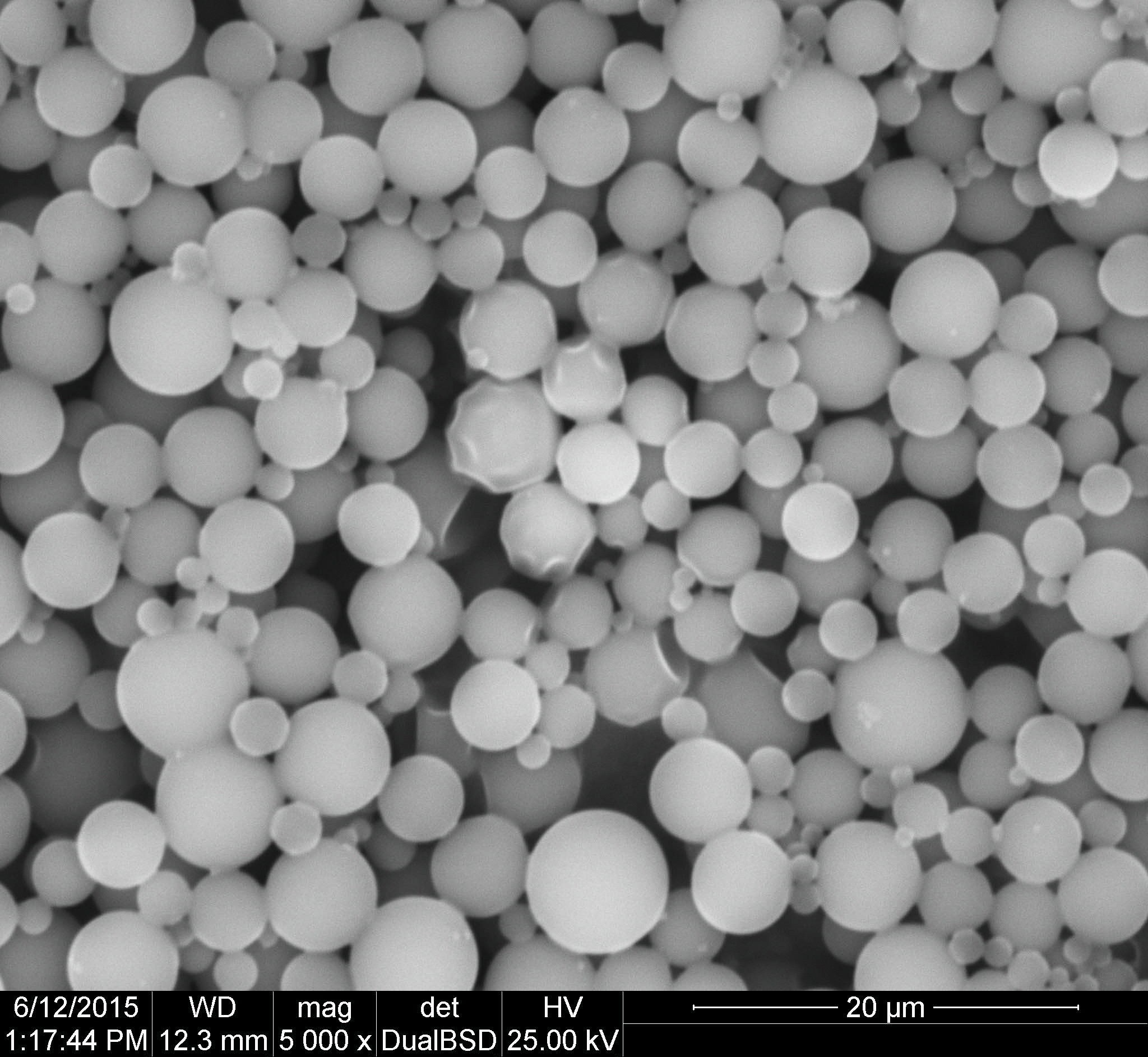

Paraffins are emulsified and micro-encapsulated at Fraunhofer ISE to investigate super-cooling of these micro-compartmented PCMs. For this purpose, different surfactants as well as PMMA and melamine resin capsule materials are used.

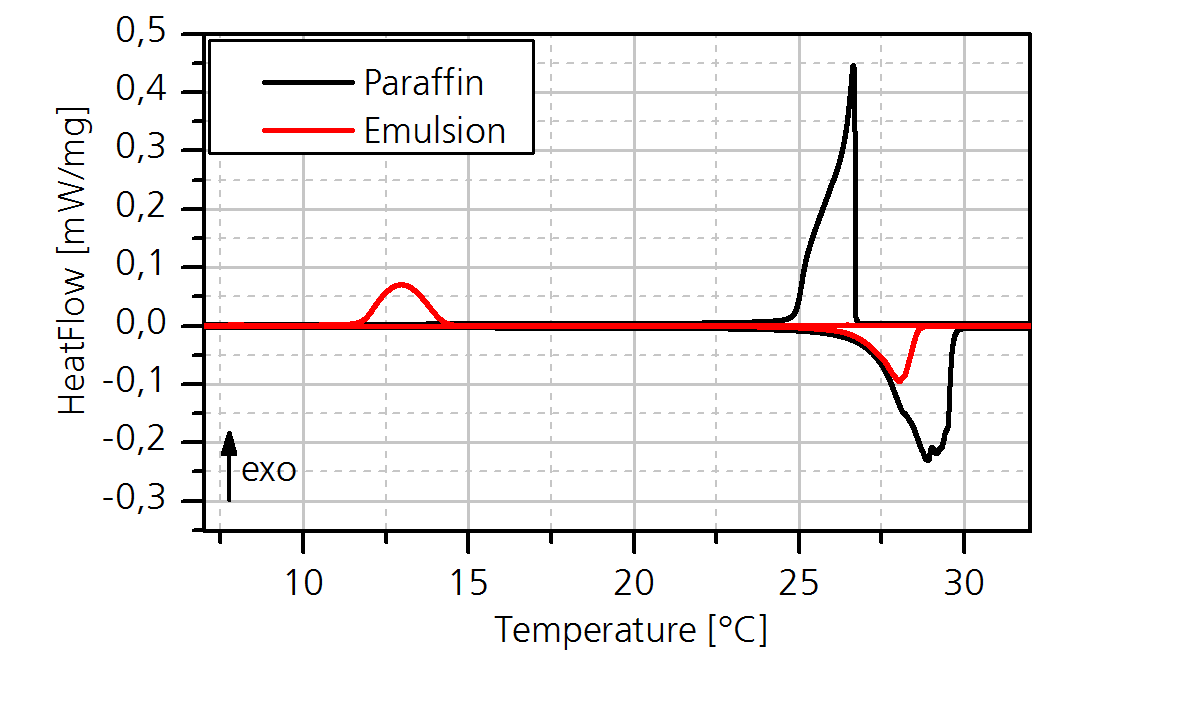

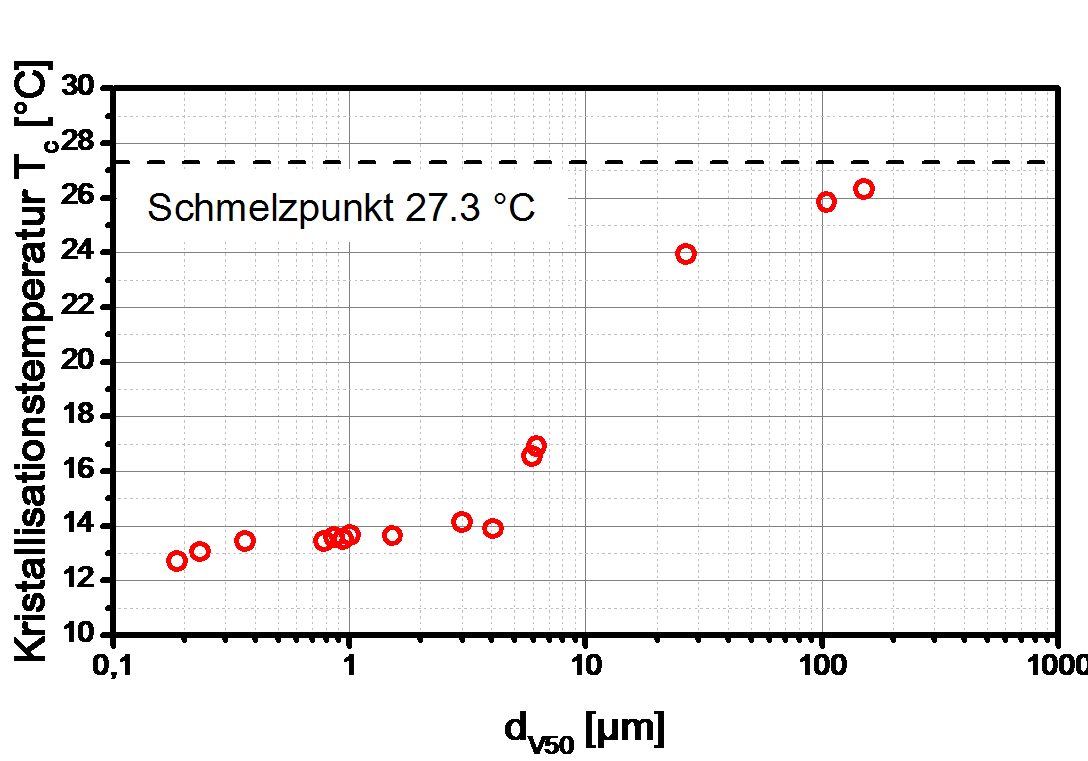

Calorimetric processes (DSC), optical processes (at ZAE Bavaria), and X-ray diffraction processes (XRD) are used for analysis the crystallization behavior. Using the DSC measurements, crystallization can be investigated in the temperature domain. Together with the XRD results, the individual peaks of the crystallization profile can be assigned to different crystal forms. The optical process enables assignment of the crystallization to the sizes of the emulsion droplets and/or micro-capsules in the time domain.

It is shown that super-cooling increases continuously with an decrease in particle size due to separation of present external nucleus. Underneath a certain size, mainly homogeneous nucleation occurs and maximum super-cooling is achieved.

Surfactants and other additives can promote nucleation of the PCM. E.g., surfactants with PCM-similar molecule structure reduce super-cooling. However, nucleus added as additive to the PCM have a stronger effect. It becomes clear that super-cooling decreases with an increase in the melting point of the additive if it shows a PCM-similar crystal structure.

The knowledge gained in the “MIKOPUK” project shows that nucleus’ can be purposefully selected through analysis of the crystal structures occurring for the micro-compartmented PCM.