| Duration: | January 2011 - June 2014 |

| Contracting Authority / Sponsors: | German Federal Ministry of Education and Reserach (BMBF), Projektträger DLR |

| Project Partners: | Quest One (formerly H-TEC Systems) |

Methane Storage – Storage of Electric Energy from Renewable Sources in the Natural Gas Grid: H2O Electrolysis and Synthesis of Gas Components

Long-Term Studies of PEM Pressure Electrolysers for PtG Applications

In the Power-to-Gas (PtG) concept, electricity from renewable sources is stored chemically as an energy-rich gas. In this joint project, carbon dioxide and hydrogen produced by electrolysis are converted into methane, which can be stored and transported in the natural gas network without difficulty. PEM (polymer electrolyte membrane) electrolysis is a particularly suitable process to produce the hydrogen: Usage of a membrane as a solid electrolyte results in high power density. Due to its excellent robustness to overloading and partial loading, PEM electrolysis can be operated very dynamically. The cell configuration enables operation at high pressure, so that there is no need for additional compressors for the methane production.

To understand the electrolysis sub-system better within the context of the complete Power-to-Gas system, we have set up a test facility with which different load profiles can be reproduced and long-term stability can be tested at the system level under realistic conditions. In addition, degradation behaviour under stationary conditions was tested over several thousand hours at the stack level.

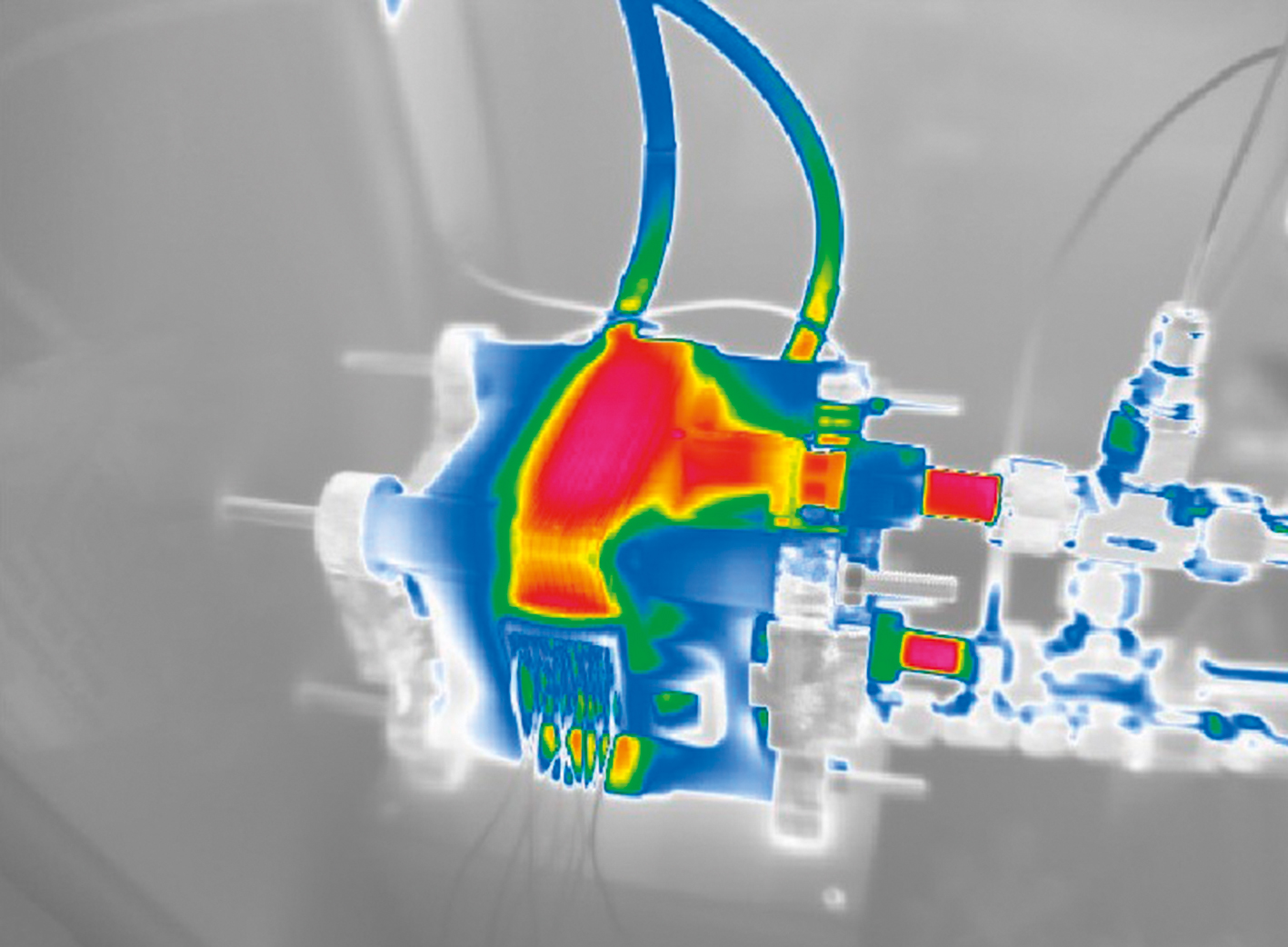

To optimize the dynamic operation management, we have characterized a 6 kW PEM electrolysis system from our partner, Quest One (formerly H-TEC Systems), and analyzed individual components in detail. Energy balances were determined for the complete electro- lyser at different load points and during externally applied, fluctuating power profiles. The results serve not only to detect losses but also to iteratively develop the hardware and operation management further in typical application cases. The experiments have demonstrated that the dynamic response of a PEM pressure electrolyser, coupled to either wind or PV electricity generation, completely fulfils the demands of PtG systems. Good efficiency values were obtained, which can still be optimized further in the lower partial load range. The utilization factors depended essentially on the ratio of the rated power of the electrolyser to that of the generator system. The gas quality of the hydrogen produced was excellent throughout the entire measurement period. Under the selected boundary conditions, up to 4700 full-load hours per year can be achieved with the simulated business model.