| Duration: | 05/2024 - 04/2027 |

| Contracting Authority/ Sponsors: | Federal Ministry of Economic Affairs and Climate Action (BMWK); Project sponsor: Forschungszentrum Jülich GmbH |

| Project Partners: | Partner: acp systems AG (Koordinator), Fraunhofer ISE, ContiTech Deutschland GmbH - Center for Functional Printing Technologies (CFPT), ELANTAS Europe GmbH, Eckart GmbH, Saralon GmbH Associated Partner: Hanwha Q CELLS GmbH, PV Nanocell Ltd. |

| Project Focus: |

Kumelle – Copper Metallization for the Production of Perovskite Silicon Solar Cells

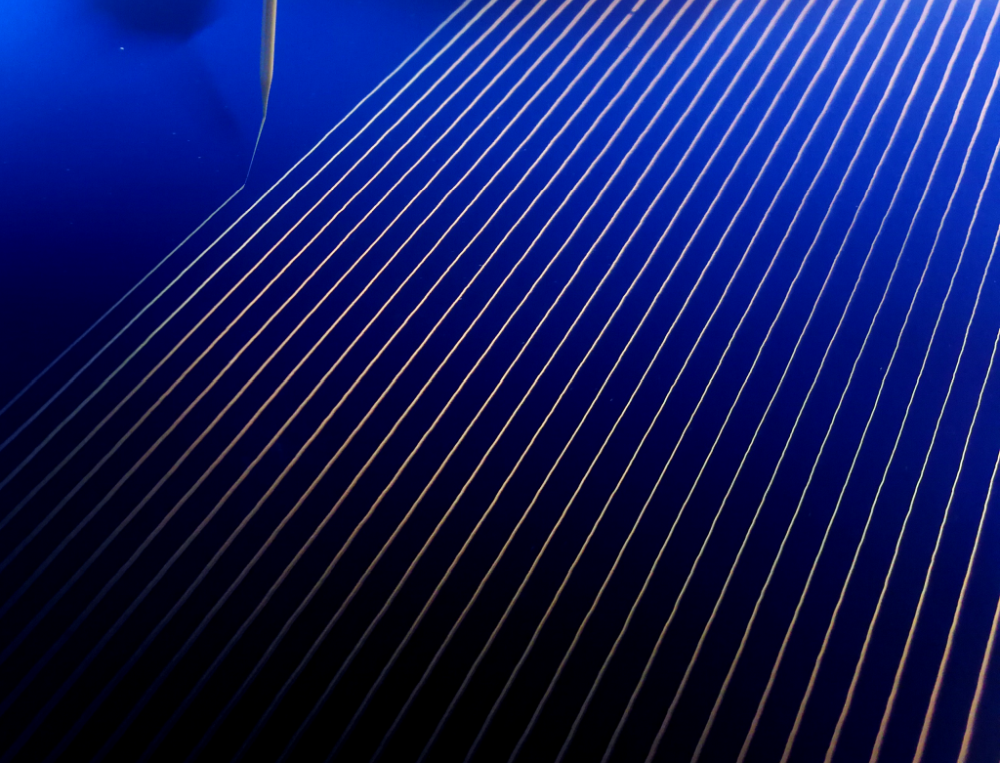

The core business of Fraunhofer ISE is the development of the next generation of solar cells. Tandem solar cells, integrated photovoltaics and sustainable production have top priority. The "Kumelle" project addresses the development of perovskite-silicon tandem solar cells, high solar cell efficiencies of over 30 % and copper metallization instead of expensive and increasingly scarce silver. The project is thus fully aligned with the core objectives of Fraunhofer ISE. In addition to the evolutionary further development of flatbed screen printing as the state of the art in production, the focus is on the revolutionary development of a new printing process (FlexTrail) in close cooperation with the consortium leader acp systems AG, which implies advantages in terms of resource efficiency, minimum feature size, material flexibility and productivity. In addition, a material-driven solution approach is being pursued with the aim of correlating cell-characteristic performance parameters with material-specific parameters and thus building up a deep understanding on the processes used.

Motivation:

The metal contacts on solar cells contribute significantly to their performance, costs and carbon footprint in production. Kumelle is therefore investigating innovative processes and materials that can be used for the production of perovskite-silicon tandem solar cells with copper contacts.

As part of the global market ramp-up of photovoltaics (PV) for the energy transition, production capacities will be successively expanded in the coming years. A production capacity of 400 GWp (per year) was reached in 2023, which is set to increase to 3000 GWp by 2035. For the production of classic solar cells, 12 tons/GWp (90 mg/wafer) of silver are mined, which could result in drastic bottlenecks in silver mining as early as 2030 with the targeted production capacity. In addition to the low and price-driving availability, the mining of silver is associated with a CO2 footprint of 144 thousand CO2eq/t and therefore significantly impairs the carbon footprint of solar cells. For a sustainable, global market ramp-up of photovoltaics, it is therefore particularly important to further increase the efficiency and performance of solar modules while simultaneously reducing silver consumption. In addition, the complete substitution of silver with copper currently appears to be extremely expedient, as copper has a higher availability with comparable electrical properties and a CO2 footprint that is two orders of magnitude lower. This does not yet take into account the reinforcing effect of copper recycling.

The "Kumelle" project meets the challenge of silver reduction/substitution with the development of printed copper contacts for perovskite-silicon tandem solar cells, which, due to their high efficiency potential in combination with industrially scalable manufacturing processes, imply a considerable differentiation potential compared to the state of the art and are therefore ideally suited for the re-establishment of PV production in Europe. In addition, the solar cells integrate copper diffusion barriers and, due to the lower currents, are more robust against electrical losses at the metal contact, which can occur with lower metal application quantities and contact changes due to oxidation, for example.

The primary project objective is to establish an industrial process series for the copper metallization of perovskite-silicon tandem solar cells in the pilot lines of Fraunhofer ISE (Technology Readiness Level = 6), which can be used primarily at the local site following the project. The FlexTrail process developed at Fraunhofer ISE, which is under patent protection, will also be brought to market maturity.

The work objectives of the overall project can be divided into the following scientific and technical work objectives.

Scientific objectives:

- Perovskite-silicon tandem solar cells with copper metallization with a conversion efficiency of over 30%

- Proof of long-term stable copper metallization according to IEC standards

- Innovative metallization processes based on flatbed screen printing, rotary printing (flexographic printing & gravure printing), as well as FlexTrail as an innovative, disruptive printing process in combination with thermal and photonic sintering technologies (laser, flash lamps)

- Specific print media with adapted particles and solvents

- Pursuit of a material-driven approach to correlate performance- with process- and material-specific parameters

Technical work objectives:

- Perovskite-silicon solar cells and modules based on sustainable process technologies

- Demonstration of a FlexTrail PV printing system

- Specific copper printing media and pigments for various printing and sintering combinations

- Conceptualization of a virtual, vertical production based on Kumelle technologies with competitive Key Performance Indicators (KPIs) for the renewed market ramp-up of production at the D/EU site

Fraunhofer ISE and Hanwha Q Cells are responsible for cell development, whereby modules are also manufactured and tested at Fraunhofer ISE in addition to pure cell development. ISE covers all essential cell technologies.

The FlexTrail process is driven by acp, Fraunhofer ISE and P.V. Nano Cell, with acp responsible for the equipment, Fraunhofer ISE for the process and P.V. Nano Cell responsible for ink development.

The screen printing process is being driven by Fraunhofer ISE and ELANTAS, with Fraunhofer ISE responsible for process and ELANTAS for paste development.

Rotary printing or flexographic and gravure printing is the responsibility of Continental and Saralon, with Continental being responsible for process and Saralon for ink development.

ECKART focuses on the development of particles and will make these available to all printing-specific ink developments, with the screen printing process being the initial focus.