| Duration: | September 2016 - August 2019 |

| Contracting Authority/ Sponsors: | Federal Ministry of Education and Research (BMBF), Projektträger Jülich (PtJ) |

| Project Partners: | AREVA H2Gen, CLARIANT, Friedrich-Alexander-Universität Erlangen-Nürnberg (FAU), Forschungszentrum Jülich – IEK 3, Deutsches Institut für Wirtschaftsforschung (DIW Berlin), Hydrogenious Technologies, Karlsruhe Institute of Technology (KIT), RWTH Aachen University, Wissenschaftszentrum Berlin für Sozialforschung (WZB) gGmbH |

| Website: | https://www.kopernikus-projekte.de/projekte/power-to-x |

| Project Focus: |

Kopernikus-Projekt Power-to-X

High-Quality Applications: Storage, Distribution and Use via Liquid Organic Hydrogen Carrier (LOHC)

The aim of this research cluster is to make hydrogen produced from renewable sources usable as efficiently as possible for applications in the mobility sector and in the chemical industry. Liquid Organic Hydrogen Carriers (LOHC) offer a novel technical possibility to enable the storage and logistics of hydrogen with high energy density in the existing fuel infrastructure.

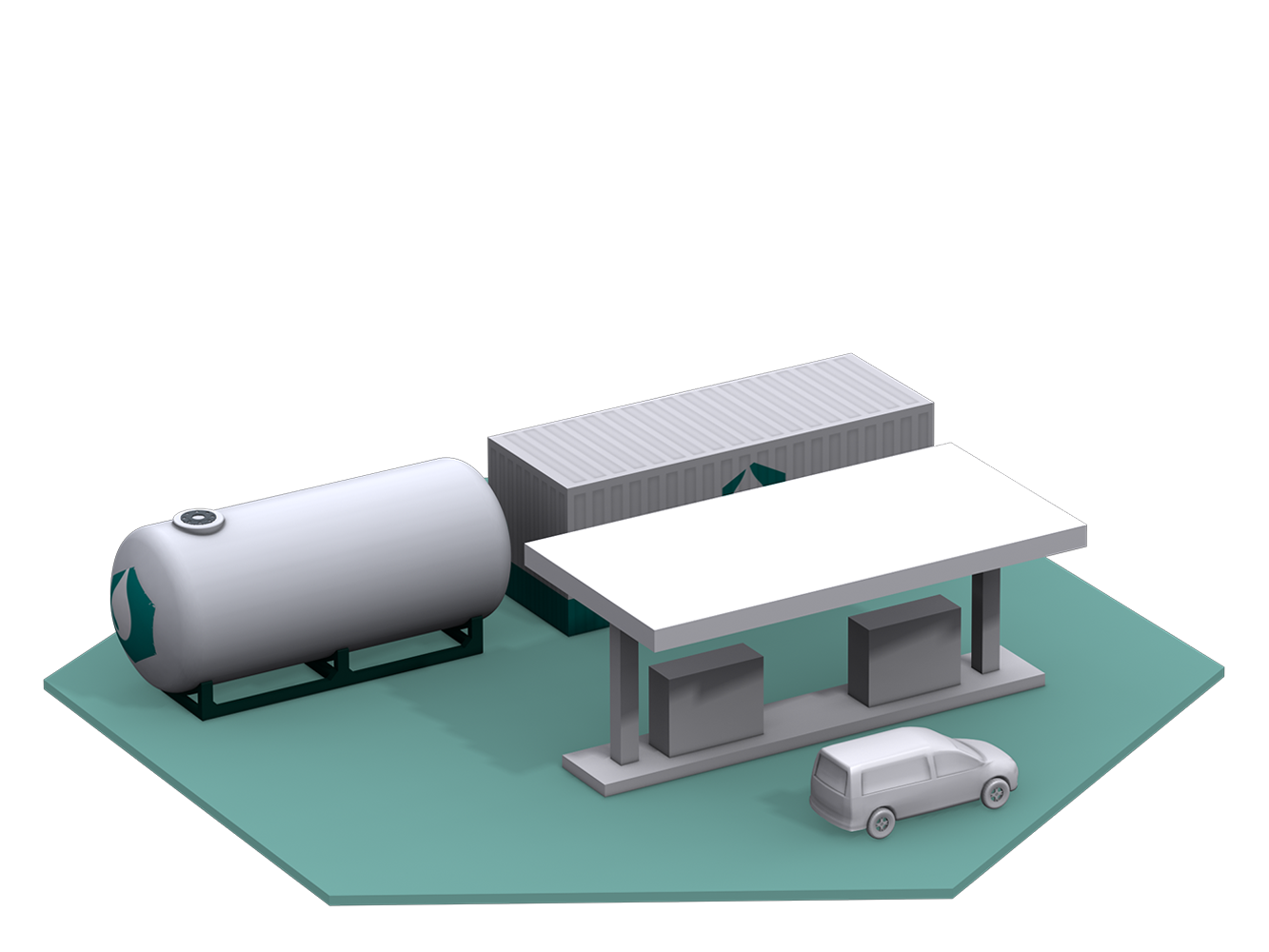

This project addresses the development and demonstration of the process chains from provided "green" electrolysis hydrogen to hydrogen release at a 700 bar hydrogen filling station or for use in the chemical industry.

In order to supply Hydrogen to Hydrogen Refueling Stations (HRS) via LOHC the hydrogen is chemically bound to a high-boiling carrier fluid (the LOHC) and released again with a catalytic reactor if required.

The application of LOHC for HRS of this project requires research concerning catalyst development, hydrogen purity, release quantity, and dynamics at a hydrogen filling station in order to enable the most economical use of the technology possible.

The focus of Fraunhofer ISE's work in this project is the integration of LOHC technology into Hydrogen Refueling Stations. For the goal of the project, the existing simulation tool H2ProSim for modelling hydrogen generation plants was adapted for Hydrogen Refueling Stations and new components (e.g. dehydrogenation unit) and cost models were developed together with the partners AREVAH2Gen, FAU and Hydrogenious. Fraunhofer ISE also examined the thermal integration of the dehydration unit into the filling station and investigated alternative ways of providing heat. Furthermore a techno-economic optimal integration concerning dimensioning, operation and scale of the components was done. With these results and together with the partners, a basic engineering for the future construction of LOHC-supplied Hydrogen Refueling station has been developed for the first time.