| Duration: | April 2010 - March 2014 |

| Contracting Authority / Sponsors: | German Federal Ministry of Economic Affairs and Energy (BMWi) |

KoMGen – Development of Next Generation Concentrator Modules

CPV Module Technology Based on Cassegrain Optics

In concentrator photovoltaics, sunlight is focussed by a cost-effective optical system onto a small solar cell. Curved reflectors can be used to this purpose, e. g. in the Cassegrain configuration. In it, the light from a concave mirror (primary optics) is directed onto the solar cell by a smaller, convex mirror (secondary optics). This results in module configurations with minimal height. We have developed and evaluated a prototype module based on this concept. We achieved a very good optical efficiency of 80 % for a geometrical concentration factor of 1000x. By choosing an elevated position for the solar cell, we eliminate the need for a third optical system, so-called tertiary optics.

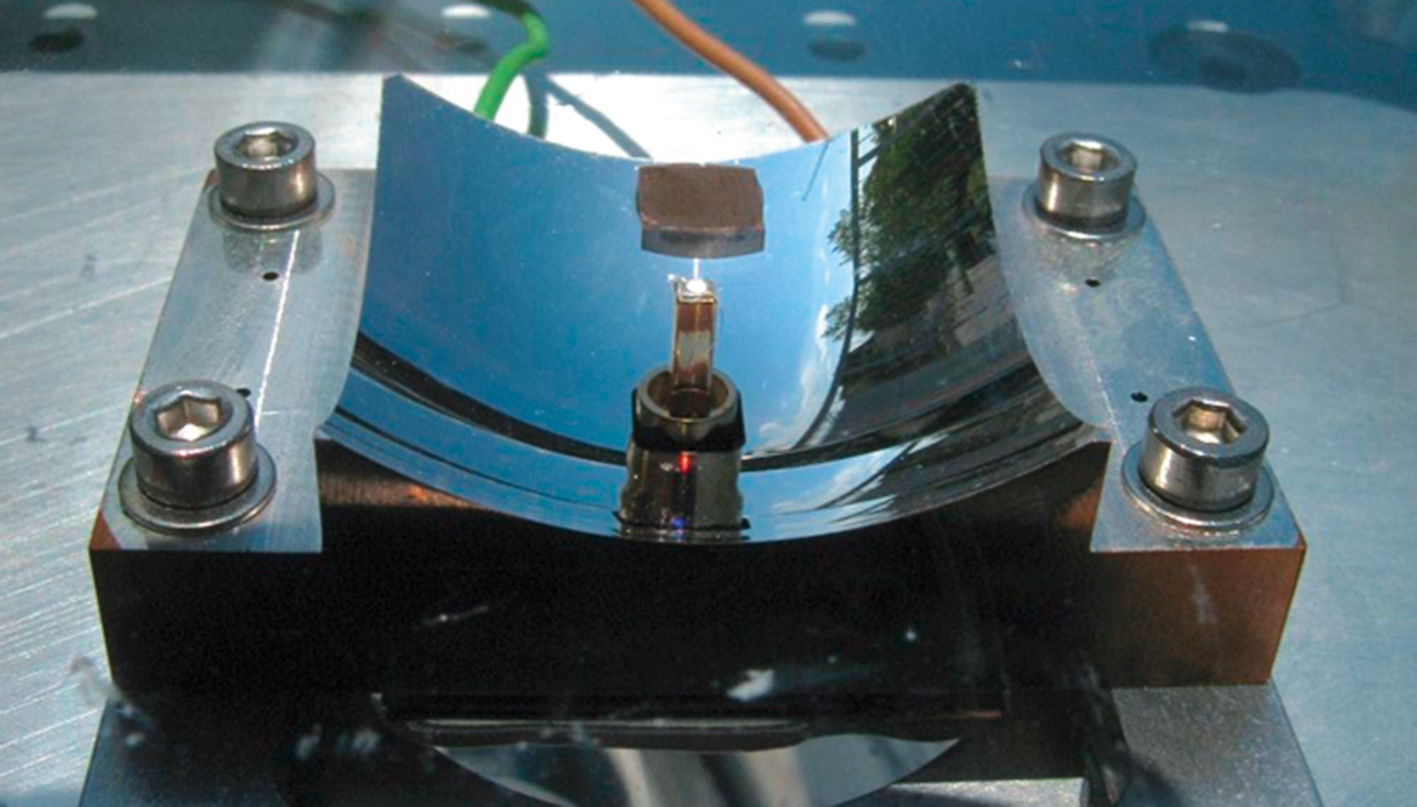

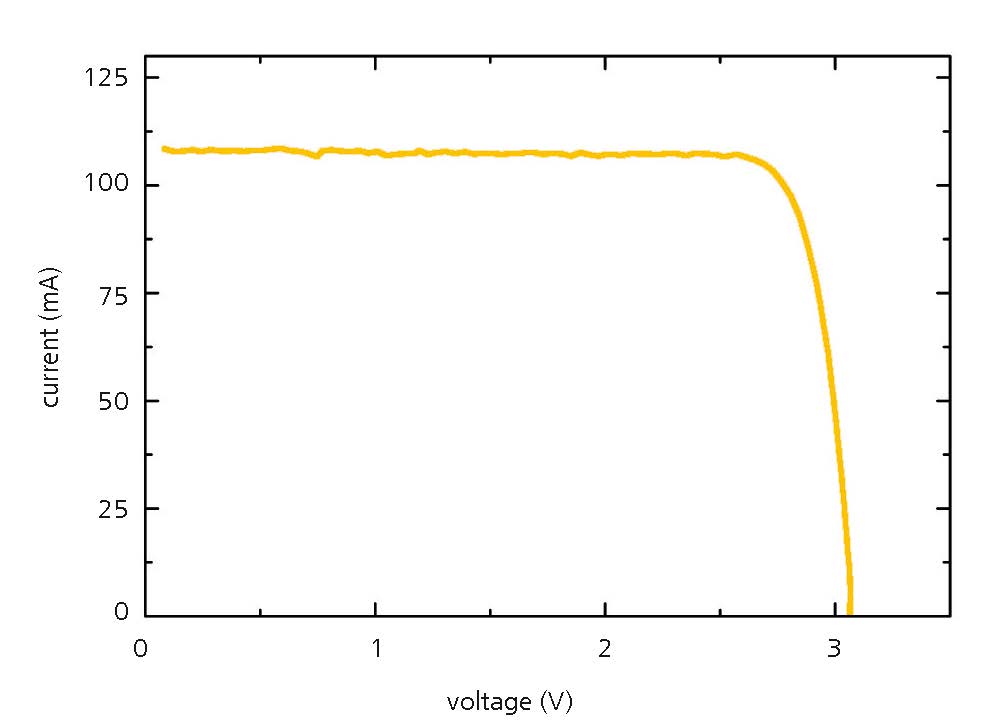

In our research on concentrator photovoltaics, we develop and analyze various module concepts. Our most recent development is a module with Cassegrain reflector optics. A major advantage of mirror optics is that chromatic aberration does not occur. In addition, we expect that the temperature dependence will be less pronounced than for Fresnel lenses. The aperture area of the module is relatively small, with an edge length of the primary optics being 32 mm. This means that a module height of less than 25 mm can be achieved. With these small dimensions, it is possible to cool the solar cell passively, i. e. to mount it on a heat spreader and transfer heat to the surroundings by convection and radiation. In addition, we mount the solar cell on a small tower. This means that the solar cell is located between the primary and the secondary optics (Fig. 1). In this way, we achieve a large acceptance angle of 0.75°, such that even if the module were misaligned by 0.75° with respect to the solar radiation, 90 % of the power would still be generated. A major aspect of our project involved constructing and investigating the concentrator optics. The optics was fabricated by diamond machining. In addition we developed optics which was produced by an injection moulding process that would be suitable for mass production. We compared the two types of optics in laboratory and outdoor measurements. The current-voltage characteristic from an outdoor measurement of the concentrator module is shown in Fig. 2. Efficiency values of 31.6 % were achieved. With continuous outdoor measurements, we are now investigating the long-term performance.

About the Project

At Fraunhofer ISE, we cover the entire development chain of concentrator photovoltaic systems (CPV), starting from solar cells or concentrator optics up to entire modules and systems, including the characterization of components and modules. In the course of the project “Development of Next Generation Concentrator Modules – KoMGen,” new concepts were developed for the CPV technology and evaluated in terms of both their technological as well as economical potential. The developed concepts form the basis for future CPV systems.

The article "CPV Module Technology Based on Cassegrain Optics" describes only one aspect of the entire project. Another part of the project focused on the "Characterization of Parabolic Reflectors for Concentrator PV".