| Duration: | 08/2017 - 01/2021 |

| Contracting Authority/ Sponsors: |

Bundesministerium für Wirtschaft und Energie (BMWi) |

| Project Partners: | Rubitherm technologies GmbH; Fraunhofer IVV; Bischof+Klein SE & Co.KG |

| Project Focus: |

KOKAP – Cost-efficient Capsule Technologies for Phase Change Materials

Latent heat storage systems can store large amounts of energy at a high energy density within a small temperature interval by means of a phase change material (PCM). The high cost of encapsulation, however, often hinders economic applications with PCM. In order to achieve high storage capacities, both the geometry and the materials of the PCM encapsulation play important roles. In the KOKAP project, macro-encapsulations from the packaging industry are being investigated for PCMs with regard to stability and performance. The aim is to offer significantly more cost-efficient capsule systems for latent heat storage in the future.

PCMs are currently offered in encapsulated form by various manufacturers. Often the products available on the market are manufactured in relatively small quantities. This leads to high costs for PCM capsules and thus PCM storage units, consisting of thousands of capsules. Therefore, large-volume capsules are regularly used, which results in a rather low thermal performance.

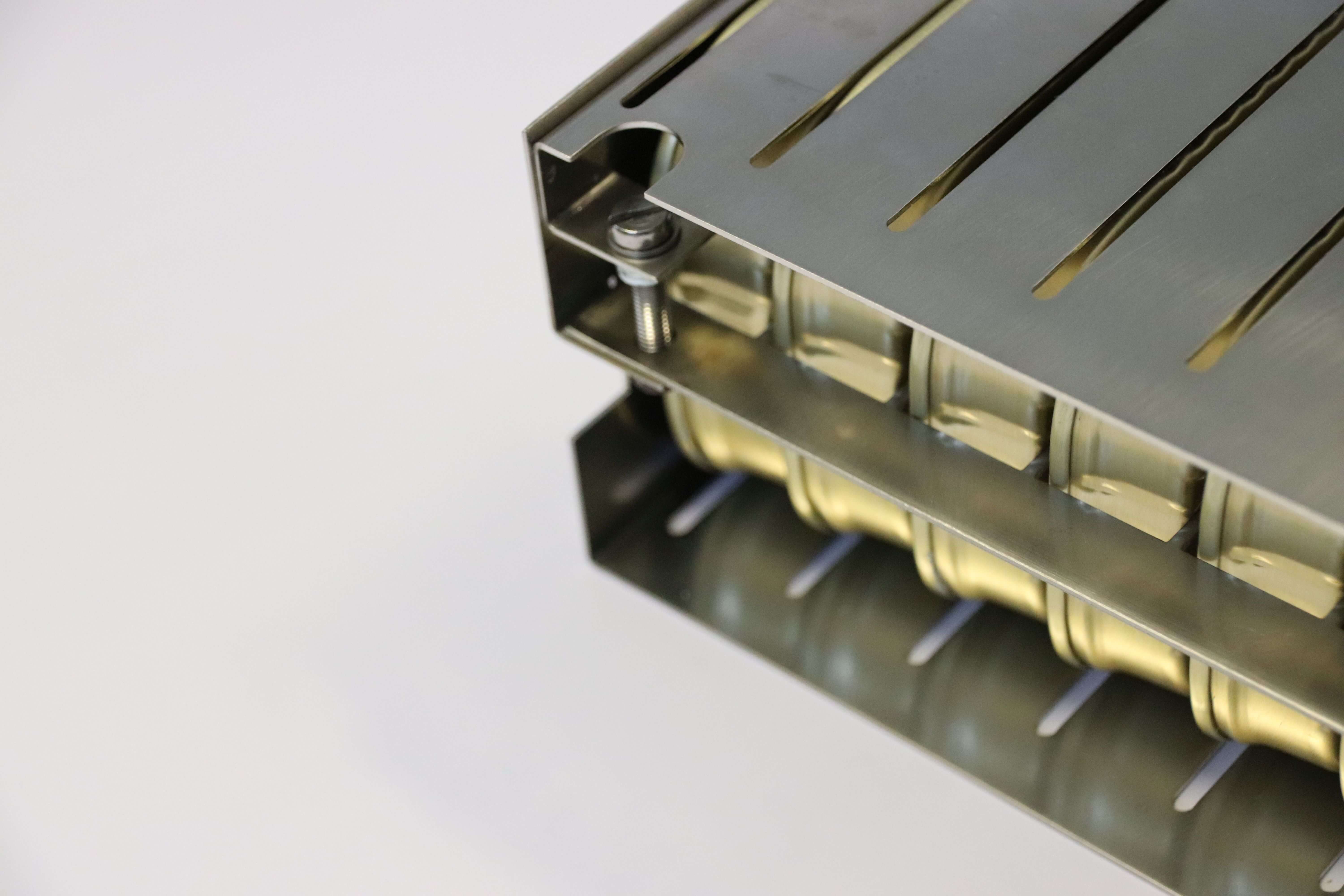

Within the KOKAP project, PCM packaging in the form of PCM capsules, such as foil , metallic and plastic packaging are developed and investigated on a centimeter scale for use as latent heat storage in water and air systems. Due to its flexible properties, foil packaging can absorb the material expansion of the PCM. By combining different materials the PCM encapsulation can be optimized based on the individual needs. Metal and plastic packaging have a stable shape, thus offering a greater protection against mechanical stress. Their stability also provides advantages in terms of stacking in the storage system and also flow. Metallic packaging provides an inherently high barrier against the migration and diffusion of PCMs, oxygen and water as well as the properties of high temperature stability and high thermal conductivity. One disadvantage is that possible deformations can be plastic rather than elastic. In addition, corrosion can occur, making corrosion protection necessary for both the inside and the outside depending on the PCM. Plastic packaging, on the other hand, is very resistant to corrosion and also mechanically more resilient than the other two types of packaging. However, the migration of organic PCM and water through the material could be a disadvantage here, as could the temperature limitations of the plastic.

The aim of the project is to evaluate the suitability of the different packaging and to identify the potential for adaptation or modification for the stable encapsulation of PCM.

For salt hydrates and paraffins in the low-temperature range, stable metallic and also plastic packaging could be identified, which are manufactured using established mass production processes, thus keeping the packaging price low. The final work focuses on the modularization of the macro capsules and the determination of the capacity in a storage tank with a volume of up to 250 l.