| Duration: | 08/2023 - 07/2027 |

| Contracting Authority/ Sponsors: | Federal Ministry of Economic Affairs and Climate Action (BMWK); Funding reference number 03EN4058 |

| Project Partners: | Bosch, Groupe Atlantic, Obrist, Ariston, Deutsche Bahn, Kermi, Hoval, Viessmann, Solvis, Faiveley |

| Project Focus: |

HP-Resilience

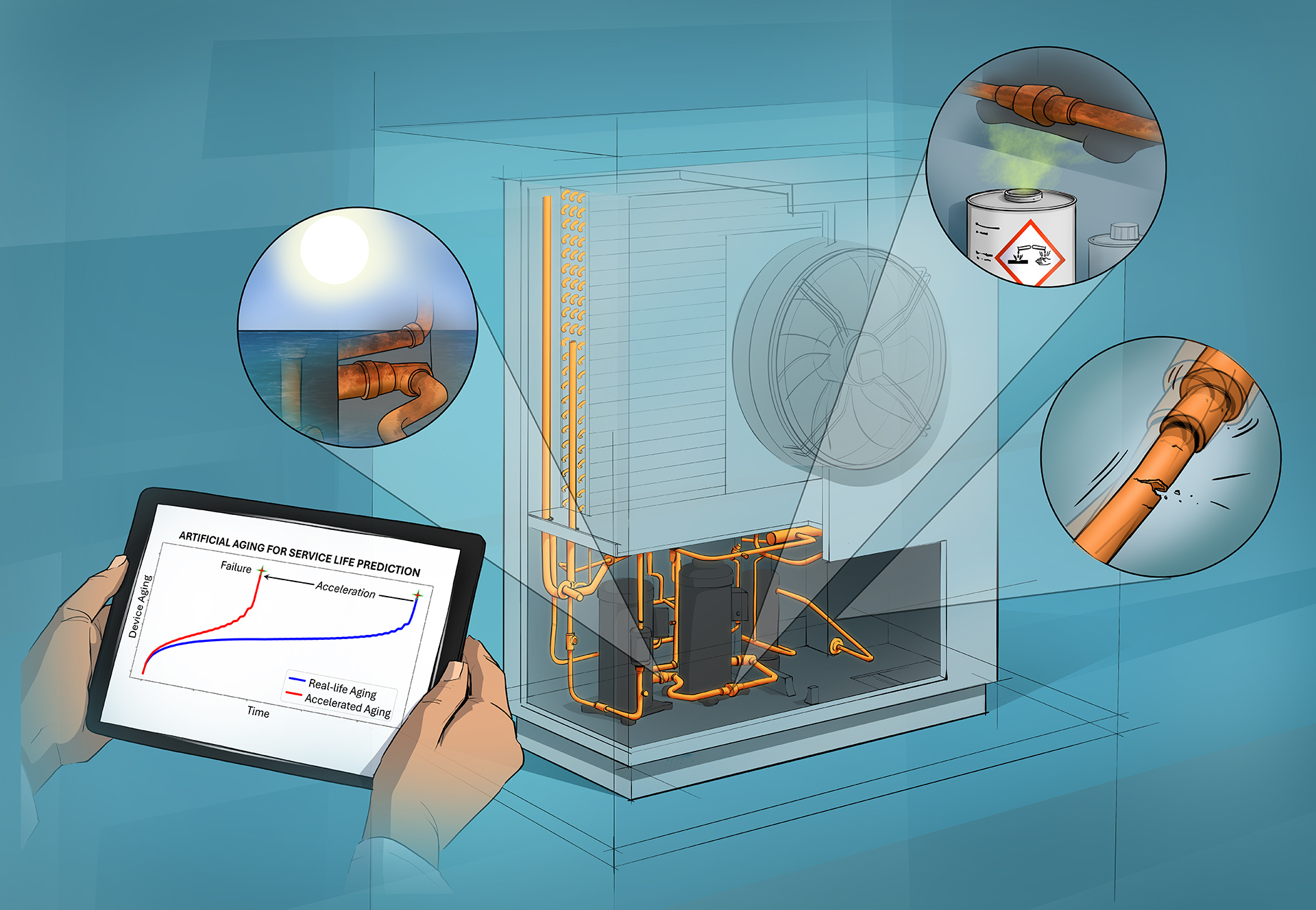

Development of methods for the artificial ageing of propane refrigeration circuits as a prerequisite for measures to extend the service life of heat pumps

Currently, more than half of German households are heated by gas and oil boilers. In addition to a dramatic dependence on fossil fuels, this accounts for over 50% of the energy consumption of the entire heating supply. Thanks to their efficiency, electric heat pumps (HPs) are significantly more climate-friendly and, when operated with electricity from renewable energy sources, can make a significant contribution to decarbonizing the heat supply and moving away from fossil fuels. In addition, the use of environmentally friendly refrigerants such as propane (R290) or butane (R600) is increasingly being enforced by law. Due to the high flammability of these refrigerants, permanent, technical tightness is becoming the focus of current heat pump developments.

As part of a Fraunhofer platform project (similar to the LC150 project), methods for artificial/accelerated ageing, targeted fault analysis and service life prediction of propane refrigeration circuits are to be developed in close cooperation with the industry (manufacturers of domestic HPs and air conditioning unit manufacturers for rail vehicles) in HP resilience. In addition, a standardized database is to be created for the risk assessment of refrigeration circuits with regard to leaks and the associated escaping refrigerant. In addition to leaks, risks based on ignition sources and accidents are also to be included in the database.

The key results of the project are intended to provide industry with a methodology to scientifically and practically evaluate the complex interaction of vibration excitation by the compressor, residual stresses after the manufacturing process as well as temperature and pressure fluctuations and varying environmental influences (e.g. corrosive atmospheres), making it possible for the first time to reliably estimate the service life of hermetic refrigeration circuits. In addition, detailed investigations of leaky components should provide a clear data basis for carrying out risk assessments for refrigeration circuits, which is necessary for compliance with legal requirements (e.g. Pressure Equipment or Machinery Directive and thus harmonized standards).