| Duration: | July 2008 - November 2011 |

| Contracting Authority/ Sponsors: | Deutsche Bundesstiftung Umwelt DBU |

| Project Partners: | Kollektorfabrik GmbH |

| Project Focus: |

HoVaLuko - Field Test with Highly Efficient Vacuum Tube Air Collectors for Solar Back-up Heating

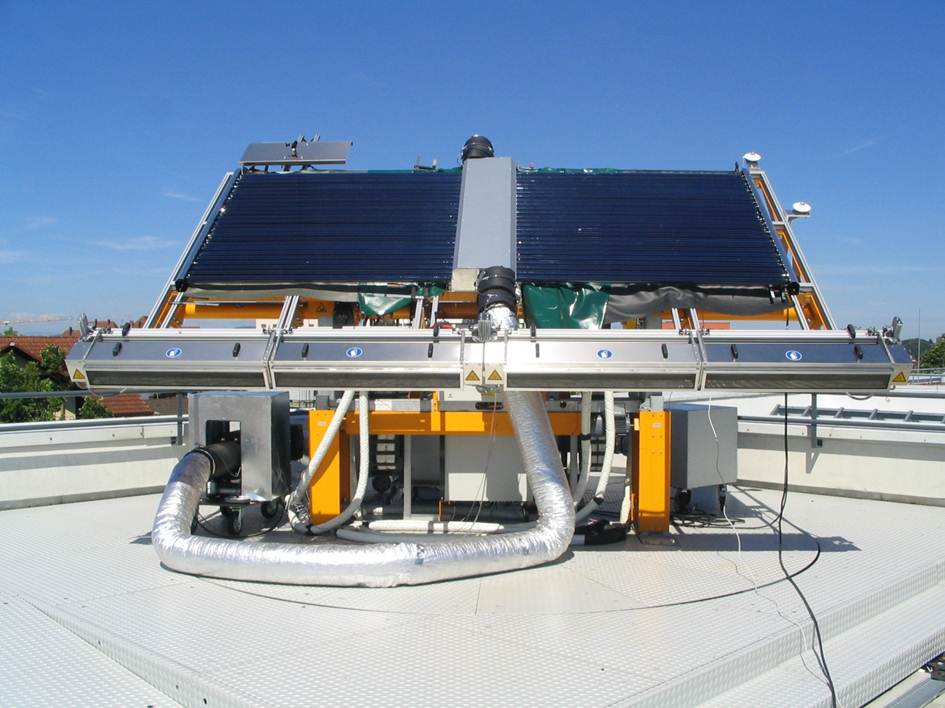

Kollektorfabrik, a company based in March-Buchheim, Germany, has developed a stagnation-proof and intrinsically safe solar air collector. One of the greatest differences in comparison with other solar air collectors on the market is its underlying collector technology. As opposed to working with a flat absorber, the solar air collector features vacuum tubes. This concept allows significantly greater temperatures and high efficiency values to be achieved. The hot air can be used directly, e.g. for air heating systems or industrial drying processes. Air-water heat exchangers can also be used to heat liquids. The collector stands out thanks to its wide range of possible uses and by the fact that it is not limited in size.

However, it has not yet been seen how the collector works in practice on a daily basis. In this project, Kollektorfabrik and Fraunhofer ISE established the economic, environmental and technical suitability of solar air collectors for use in solar back-up heating. Hydraulic and control concepts for integrating these solar air collectors were developed. The measurement data recorded will help monitor the systems and provide balance sheets relating to their energy yield. The project also aimed to establish whether the use of low-cost measurement technology is suitable for measuring heat flow. A further objective was to develop the possibility of integrating this inexpensive method of monitoring functionality into any solar installation. In total, eight solar air collectors were planned, built and measured for back-up heating.

The project involved a series of subtasks:

- Construction of eight field installations

- Selection and characterization of low-cost measurement technology

- Installation of measurement technology and a monitoring system

- Optimization of operation through evaluation of measurements

- Measuring and characterization of heat exchanger and rock bed storage

- Optimization and further development of the system’s heat exchanger

- Evaluation of the system’s key performance indicators