| Duration: | 11/2022 - 10/2024 |

| Contracting Authority/ Sponsors: | VDI/VDE Innovation + Technik GmbH, Project sponsor of the Ministry of Economic Affairs, Labour and Tourism |

| Project Partners: | Innotech Ingenieursgesellschaft mbH |

| Project Focus: |

HORMEE

Development of a Tray Dryer for Fruit, Vegetables and Herbs with Regenerative Multi-Source Energy Supply

Drying processes are part of many production processes in the agricultural and food sector. Conventional drying processes usually work with a heated air flow. The drying effect can be optimized by using heat pumps and sorption technology. This results in a number of beneficial effects. On the one hand, the reduction of the process temperature enables drying that preserves vitamins and increases product quality in terms of bite resistance and color, and on the other hand, a more energy-efficient drying process. The thermal energy can be obtained from solar collectors, waste heat or a solar-powered heat pump, for example. The energy efficiency of the drying process is to be optimized to such an extent that the electrical energy for the heat pump and the fan in the dryer can be generated via a coupled photovoltaic system.

The aim of this project is to develop a drying system that can be operated entirely with renewable energy. The thermal energy for heating can be obtained from solar collectors, waste heat from biogas plants or from a heat pump, for example. The energy efficiency of the drying process is to be optimized to such an extent that the electrical energy required for the heat pump and for the fan in the dryer can be generated by a photovoltaic system. Solar operation poses further challenges for drying: an industrial drying process must be plannable, i.e. it must run within a certain time frame and deliver almost the same drying result with the same settings. One aim of this project is therefore to develop an adaptive control algorithm and implement it in practice to respond to fluctuations in the energy supply.

This tool makes it possible to automatically adapt the dryer output to the fluctuating energy supply from the sun without negatively affecting product quality, energy consumption or drying time. In addition to the process-specific optimization of drying, the goal of a completely regeneratively supplied dryer also requires an improvement in primary energy efficiency through additional measures such as heat recovery, the coupling of regenerative energy and, in particular, the use of a heat pump. The use of heat pumps for the simultaneous provision of cold and heat, but also the use of sorption technology, can optimize or accelerate the drying effect by reducing the process air humidity. This allows various beneficial effects to be utilized during drying. Reducing the process temperature enables the production of dried products with properties that cannot be achieved with conventional processes, e.g. drying that preserves vitamins or increases product quality such as bite resistance and color. Compared to conventional drying, the drying speed and thus the throughput of the system can also be increased at the same temperature, or the same drying speed can be achieved at a reduced temperature.

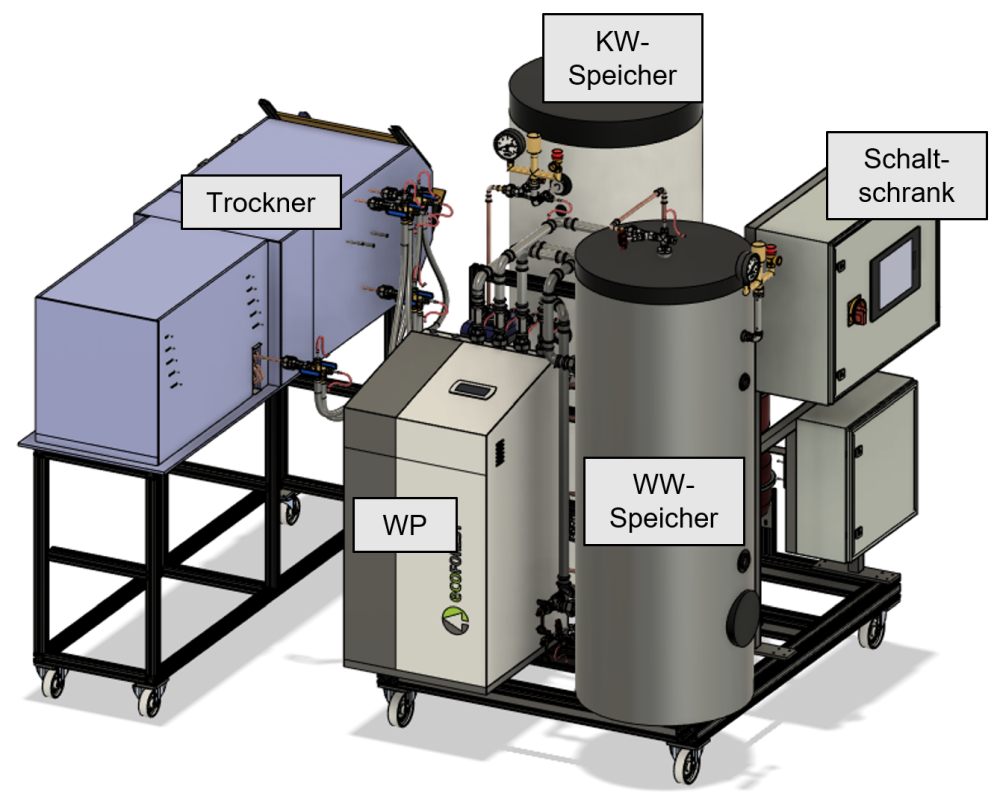

Finally, the developed components and processes will be implemented in a demonstrator and measured.