| Duration: | 02/2021 -07/2023 |

| Contracting Authority/ Sponsors: | Federal Ministry for Economic Affairs and Energy (BMWi) |

| Project Partners: | FARO Technologies, Inc. |

| Project Focus: |

HelioSense – Development of an Innovative 3D-Laser-Soiling Scanner for Autonomous Application in Solar Thermal Power Plants

The yield and operating strategy of solar thermal power plants depend on the high reflectivity as well as the good shape and positional accuracy of the concentrators (e.g. heliostats or parabolic troughs). The efficiency of solar thermal power plants is approximately directly proportional to the directional reflectance of concentrating mirrors, which is reduced by soiling. Similar reductions in yield can be caused by defects in the shape and tracking position of the mirrors, which misdirects reflected radiation. One percent loss of reflectance due to soiling can result in losses of €200,000 to €500,000 per year. Up to now, there have been no suitable measurement methods for an accurate high-resolution and automated recording of the factors of soiling, form and positional accuracy. In the project HelioSense, a novel solution approach based on LIDAR technology and extensive supplement algorithms is being developed and tested.

In the joint research project HelioSense, FARO Technologies, Inc. and Fraunhofer ISE are developing and testing a novel method for measuring large-area spatially resolved soiling as well as the shape and positional accuracy of heliostats and parabolic troughs, using 3D laser scanning in the solar field of solar thermal power plants (CSP, Concentrated Solar Power).

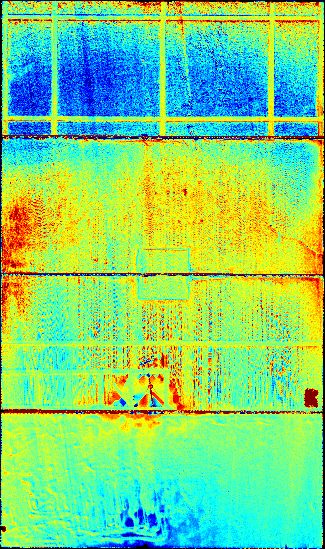

Highly accurate 3D laser scanners determine the distance between the measuring station and the point of impact by means of reflected light pulse signals. With up to 1,000,000 measuring points per second, a scanning of the surroundings is possible in a very short time. The dimensionless "intensity" of the reflection is recorded as a quality criterion for the measuring point. In the development project, it serves as an indicator to determine the degree of soiling of the mirror surfaces over a large area using new algorithms. For this purpose, a transfer function is determined between the signal of the laser scanner and CSP-relevant soiling. Through the use of new evaluation algorithms and data linking, the angle-dependent reflectance can thus be recorded automatically over a large area at the high-speed common in 3D scanning.

In the future, the measurement of the solar field is to be automated without interrupting the operation of the power plant. The use of an autonomous ScanBot, but also the measurement in conjunction with cleaning trucks, is being investigated to enable regular measurements of the huge mirror fields. The recorded data should support the power plant operator to optimize the operation and cleaning strategy for the power plant. Therefore, the development of a suitable platform with data processing is an essential part of the development project. The provision via the platform of FARO Technologies, Inc. in the form of a digital twin will be adapted to the requirements of the operators as an interface.

As part of the research project HelioSense, a 3D-laser-soiling scanner is being developed and tested for autonomous use in solar thermal power plants. With the help of this novel technology, a significant contribution is made to the efficient operation of solar thermal power plants, as the cleaning and maintenance plans for the solar field can be created quickly and reproducibly and operating strategies can be optimized through large-area recording, automation, digital processing and analysis. The comprehensive data acquisition and digitalization in the power plant can make an important contribution in the future to increasing yield and performance or reducing the electricity generation costs in solar thermal power plants.