| Duration: | 01/2021 - 07/2024 |

| Contracting Authority/ Sponsors: | Bundesministerium für Wirtschaft und Klimaschutz (BMWK) |

| Project Partners: | PVATePla AG; Coveme (associated); Meyer Burger (associated) |

| Project Focus: | |

HAST development

Non-destructive evaluation of the aging properties of module components and validation of adapted HAST methods.

The goals of "ZeitnaH" are to accelerate and validate testing and qualification methods for PV modules and contained materials. The methods are intended to help various players along the PV value chain to make their development processes more time- and cost-efficient and to increase product quality.

For this purpose, highly accelerated stress tests (HASTs) as well as mechanical characterization methods and scanning acoustic microscopy (SAM) will be investigated and optimized. In addition, a method for the identification and consistency assurance of the materials (used) employed (analytical fingerprint) is being developed.

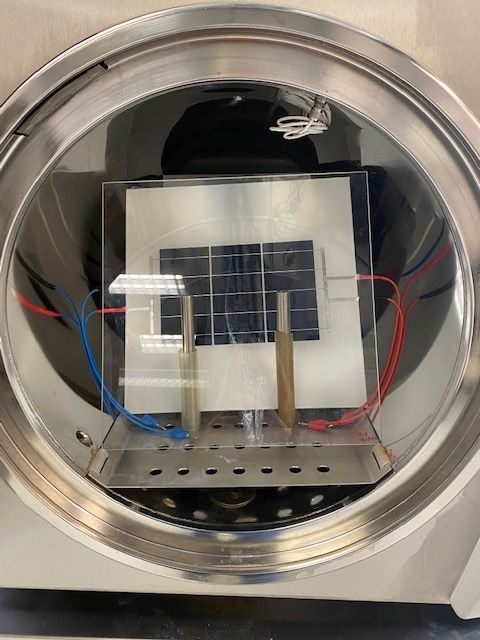

The development of the HASTs focuses in particular on the pressure cooker test, in which the PV modules and materials are exposed to high temperatures and extreme water vapor pressure (e.g. 120 °C, 2 bar). In a first step, its informative value as an accelerated test method is compared with the common Damp Heat Test (85 °C, 85 % rel. humidity, IEC61215:2021-2). For this purpose, extensive series of experiments are carried out with systematic variation of test parameters and material compositions.

For better quality assurance, destructive and non-destructive characterization methods are also being developed. Those aim to identify employed materials (mostly polymers) and also check the materials and material properties for consistency. which allow the materials used, especially polymers, to be identified and their properties and quality to be checked for consistency (analytical fingerprint).

In addition, the current methods for determining adhesion (peel tests) are being tested for their validity and are also being further developed. Methods such as the Dual Cantilever Beam Test will be tested for their suitability for PV materials and PV modules.

For the further development of the SAM, possibilities are being developed to investigate the properties of the installed materials at different temperatures (range). In addition, a measurement set-up is being developed that will allow a more precise determination of the Young's modulus of the installed materials.