| Duration: | 3/2019 - 8/2022 |

| Contracting Authority/ Sponsors: | Bundesministerium für Wirtschaft und Energie (BMWi) |

| Project Partners: | KRAFTTBLOCK GmbH, Comet Schleifscheiben GmbH |

| Project Focus: |

FENOPTHES – Development and Optimization of Filler Materials for Thermal Storage

The aim of the project is to develop and optimize cost-efficient filler materials for high-temperature storage systems and to test a high-temperature storage system in an industrial application. The application area of the filler materials is thermal storage for waste heat recovery as well as solar thermal and fossil power plants with liquid heat transfer media (thermal oil or molten salt) or with gaseous heat transfer media such as air.

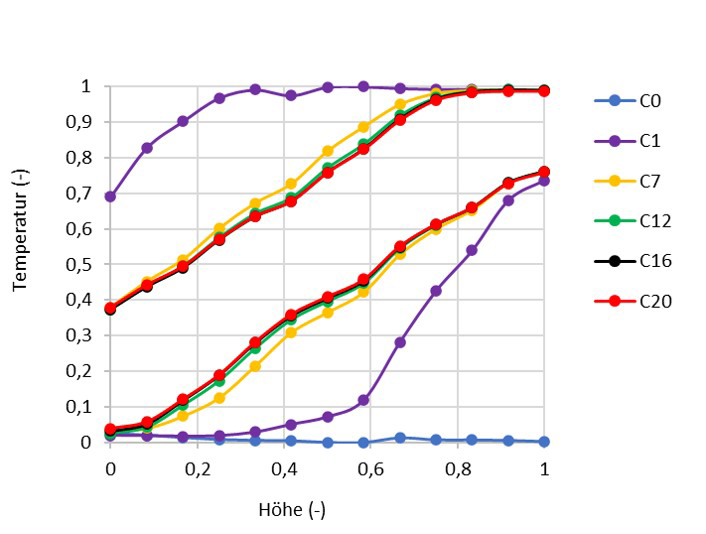

Fillers as storage media in thermal storage systems can replace other, expensive storage media or improve the storage properties. The fillers investigated here consist of phosphate binders and additives. Various materials can be used as additives, resulting in application-optimized properties at low material costs. In the project, different filler shapes are being produced to investigate the influence of their geometry on the thermal efficiency of the storage. First, the compatibility of the filler material with different high-temperature media was investigated by means of ageing tests. Subsequently, chemical analyses of the fillers and fluids were carried out, as well as a test on the mechanical stability of the fillers. In parallel, the different filler configurations were thermally characterized, initially not with high-temperature media such as thermal oil or molten salt, but with water. As a result, different filler configurations show different temperature profiles and time histories during cyclic charging and discharging of the storage (cf. figure). A selected configuration of the packing was additionally measured in a molten salt tank. To this end, the existing molten salt infrastructure was expanded to include an additional storage facility, which offers the possibility of inserting packed beds

This storage technology is intended to improve the energy efficiency of industrial processes through the time-independent utilization of recovered heat.

The construction and operation of a demonstrator, in which the technology is tested in an industrial application, serves to demonstrate the efficiency and reliability of this technology to lower barriers for market entry.

Fraunhofer ISE coordinates the project, is in charge of the numerical and experimental investigation of mechanical and thermal properties of dual-media storage systems and supports the material development and system integration of a storage prototype. The prototype, which is being built at Comet Schleifscheiben GmbH, is used for the intermediate storage of waste heat from the firing of ceramic grinding wheels until reintegration into the process.