| Duration: | 12/2024 - 05/2028 |

| Contracting Authority/ Sponsors: | Funded by the European Union (EU) |

| Project Partners: | FIB Spa – FAAM, EnBW Energie Baden-Württenberg AG – EnBW; Enel Green Power SPA – EGP; Arkema France SA – Arkema; Up Catalyst OU; Fundacion Cidetec – CIDETEC; Universidad de Alacala; University of Warwick; Karlsruhe Institut für Technologie – KIT, Uniresearch BV; Senec GmbH |

| Website: | Episode LinkedIn - Episode |

| Project Focus: |

EPISODE – European Produced SustaInable SODium-Ion BatteriEs for Stationary Applications

As part of the “EPISODE” project, battery cells and battery storage systems based on sodium-ion cells are being developed in an innovative European value chain as a pioneering alternative to conventional lithium-ion battery storage systems. These innovative storage systems are characterized by their high energy density and remarkable longevity. Thanks to their very high energy efficiency, intrinsic safety and excellent recyclability, they represent a particularly sustainable product. At the end of the project, the performance of this technology will be impressively demonstrated with a 6.2 kWh battery storage system in continuous operation.

The “EPISODE” project has set itself the task of developing battery cells and battery storage systems based on sodium-ion technology. The battery materials produced by the partners, hard carbon from biomass for the anode, layered oxides for the cathode and electrolytes with ionic liquids, guarantee the development of a particularly sustainable cell. In contrast to the prevailing lithium-ion technology, the use of lithium, cobalt, graphite and copper can be dispensed with. The hard carbon produced is sustainable and the electrolyte developed is also safer than the electrolytes used in existing lithium-ion technology.

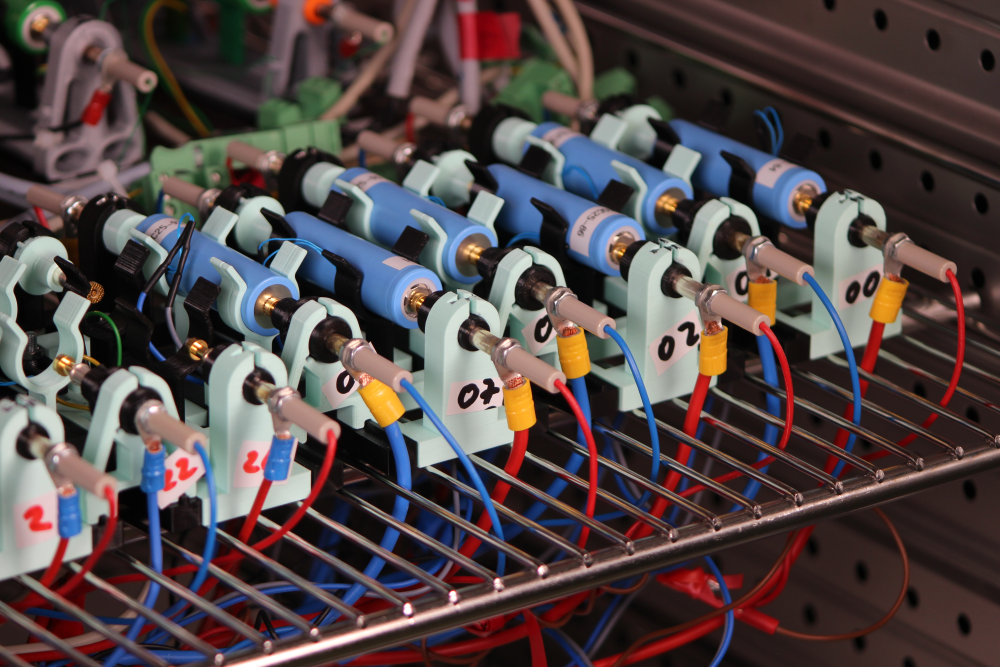

Fraunhofer ISE ensures the development of the cell through comprehensive safety tests in a protected test environment. In the event of potential thermal events (thermal runaway), in which high temperatures, pressure waves and large, sometimes toxic quantities of gas are generated, the resulting gas volumes and their compositions are analyzed and the spread of energy is considered. The results of these tests flow directly into the development process of the cells and systems in order to optimize the developments. The cell size is being scaled up by the project partners from button cells to industrial 20 Ah cells, with the aim of developing a cell that passes all safety tests relevant to lithium ions and is less critical in its behavior than cells based on lithium iron phosphate.

Based on extensive preliminary work on commercial cells with different cathode compositions, we will model and simulate the cells developed in the project with regard to performance and ageing. In this way, we are making a significant contribution to achieving the benchmark, which envisages a service life of more than 5000 full cycles for the cell.

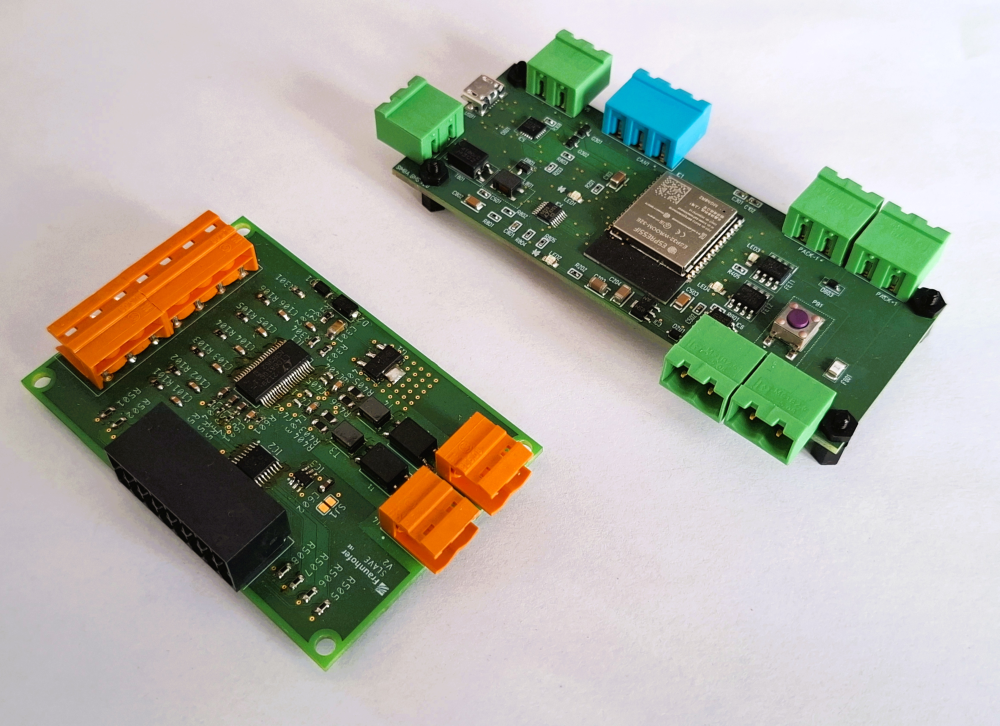

At Fraunhofer ISE, we are developing a battery management system (BMS) for this cell chemistry that uses MQTT to transmit safety-relevant data and performance data in real time. This modular BMS is being developed for a module size of 2.1 kWh and optimized in terms of computing power, costs and efficiency. With the new BMS, it will be possible to document the entire life cycle of each module. The BMS will be integrated into the newly constructed modules and battery systems. At the end of the project, a 6.2 kWh home storage system will be realized, which will prove the quality of the new technology in a trial operation of three thousand hours.