| Duration: | December 2016 - December 2017 |

| Contracting Authority/ Sponsors: | Ministry of the Environment, Climate Protection and the Energy Sector Baden-Würtember; Projektträger PTKA |

| Project Partners: | Unigea Solar Projects GmbH |

| Project Focus: |

DSW – Planning and Feasibility for Direct Solar Hydrogen Generation for Mobility

Green hydrogen is currently mainly generated from wind or excess electricity in demonstration plants, which are not economically viable and usually cease operation after the end of the funding period.

This project therefore investigates the creation of the technical concepts and the technical/economic feasibility of a direct coupling of PV via DC-DC regulators with PEM electrolysis in order to economically generate hydrogen in an off-grid PV electrolysis plant.

The present project aims to recombine existing technical components to produce green hydrogen in a technically and economically efficient way.

The long-term objective of the project is the construction of a directly solar-coupled hydrogen plant that enables efficient and economical generation of hydrogen from green electricity via direct DC-DC coupling between electrolysis and PV.

In order to achieve this goal, however, a number of technical and economic issues still needed to be solved in this project:

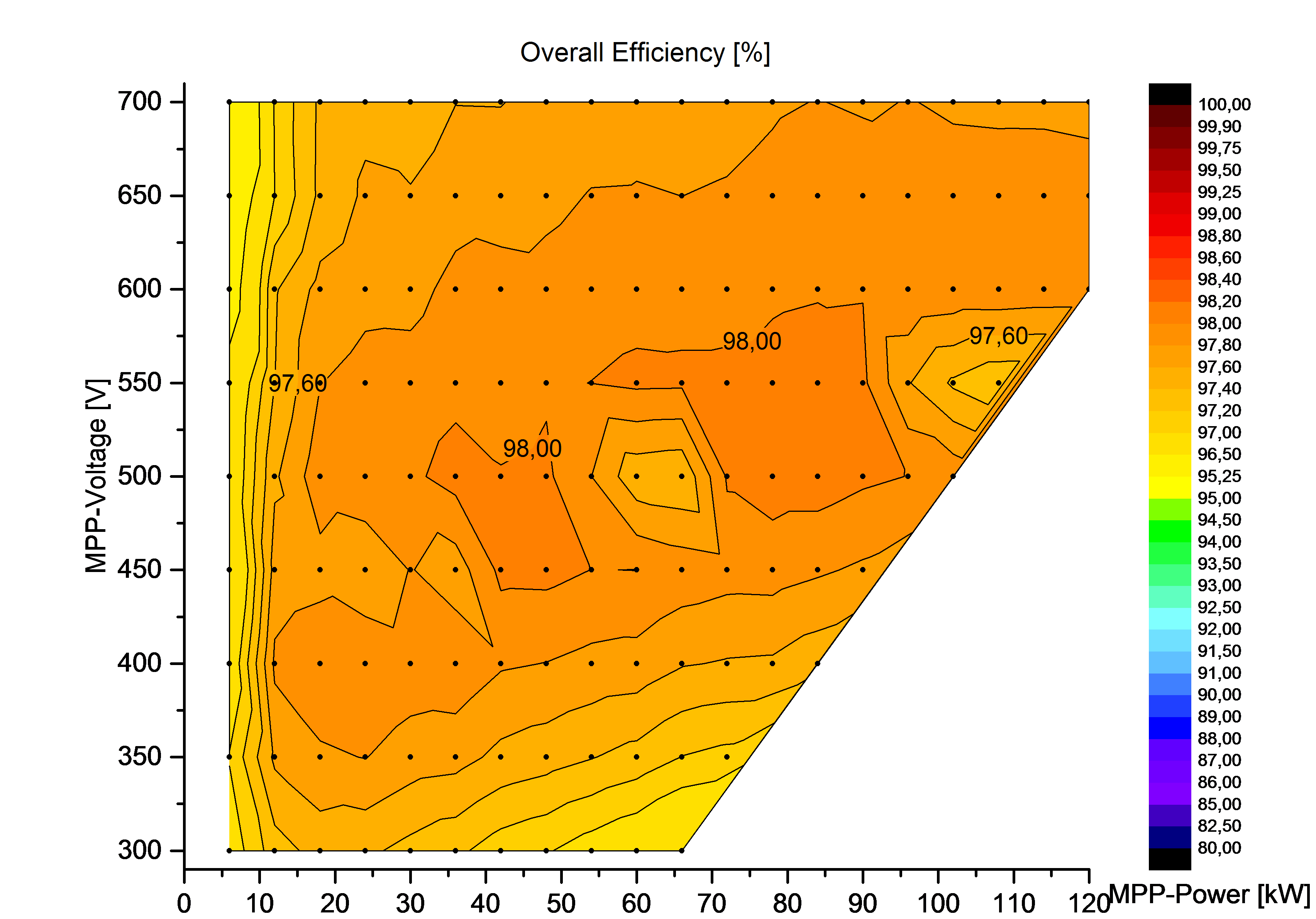

- Testing and characterization of of a DC-DC converter as key element of the DC-DC-coupling.

- Evaluation of the impact of direct coupled operation on the lifetime of the electrolyzer

- Development and optimization of the electrical system topology (which components are operated with DC, which with AC, what does the connection to the public power grid look like, what voltage levels do we need at different parts of the plant, how do we cope with night time?)

- Concept and Optimization of the photovoltaic system optimized towards a maximum hydrogen yield and towards hydrogen consumption profiles)

- Techno-Economical analysis of different adaptions to the business model and to the plant concept

- Conception and techno-economical optimization of the final plant

The result is a rough concept of the plant, i.e. the establishment of a validated business model, a technical process classified as feasible and partly tested and rough electrical and process schematics including sizing, cost structure of the plant, operation stategy. These results are the basis for a H2 generation plant, which is planned to be built in the near future by our project partners.

The project significantly contributes to mastering the initially difficult transition from fossil to carbon-free energy sources, especially in the mobility sector.