| Duration: | 11/2017 - 04/2021 |

| Contracting Authority/ Sponsors: | Bundesministerium für Wirtschaft und Energie (BMWi) |

| Project Partners: | GES Gebäude-Energiesysteme GmbH; ee concept GmbH; acp systems AG; HTWG Konstanz |

| Project Focus: | |

| Website: | Design2PV |

Design2PV – Efficient BIPV Modules with Innovative Design

Development of industrially manufacturable BIPV modules with high efficiency, innovative design and great design freedom

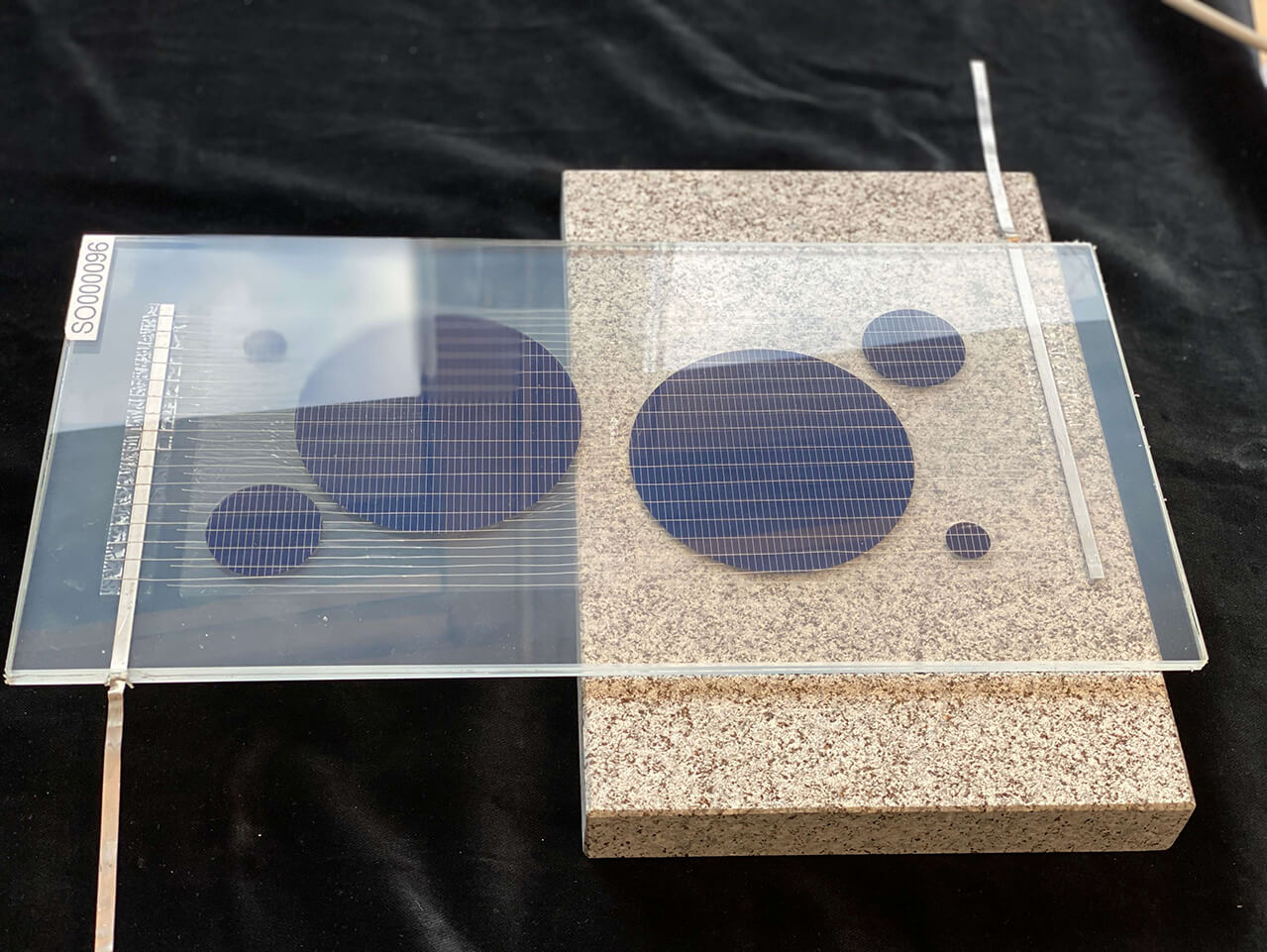

The aim of the project is to develop BIPV modules with high efficiency, innovative design and wide design scope based on a new idea for the electrical interconnection of crystalline silicon solar cells in different sizes and geometrical patterns. The modules are to be designed as glass-glass modules. By using a multi-wire interconnection, certain areas of a module can be covered with solar cells while other areas can remain transparent. Design2PV modules thus achieve a partially transparent appearance and enable very good aesthetic integration in front of opaque surfaces, in glazings or in semi-transparent roofing applications.

In the "Design2PV" project, BIPV modules with high efficiency, innovative design and wide design scope are being developed. These newly developed modules are intended to drive the use of building-integrated photovoltaics (BIPV). These modules would also be much more attractive for building renovation.

The idea: A PV cell can consist of several sections connected in parallel, which have different shapes. The cell strings can be manufactured with such fragmented cells using multi-wire technology. Since the current is conducted over many wires, the wires can be so thin that they are no longer visible even from a medium distance. Individual cell clusters can be aesthetically designed and the sub-cells within them can be connected in parallel. Adjacent cell clusters are then connected in series, as with conventional solar cells. In ideal operation, the Design2PV module delivers an output corresponding to the fraction of area that is covered with solar cells.

This technology enables design freedom: The subcells of different shape, size and color can be arranged relatively freely. Structures, patterns or gradients can be created by arranging the subcells. The cell clusters, modules and components can be generated in different sizes, and at the same time they have an aesthetic, almost pictorial effect.

Together with the project partners, the project is working on the technical implementation of the interconnection and module technology (acp systems AG, GES Gebäudeenergiesysteme GmbH), on the construction process integration and on a pilot installation (ee concept GmbH and HTWG Konstanz). The project has already produced sample modules with open-circuit voltages of over 670 mV per cell cluster, short-circuit currents of over 4 A (at 45 % cell occupancy and 55 % transparency) and fill factors of over 70 %. In a pilot installation, modules were installed in the façade as well as in the roof and monitoring of the system is underway.

The semi-transparent Design2PV modules are suitable for aesthetic integration in front of opaque surfaces (e.g. ventilated facades), in glazings or in semi-transparent roofing applications. The aim is for the new modules to make the use of BIPV much more attractive, especially in the renovation of buildings.

Publications on this subject:

- J. Eisenlohr et al., Novel, semi-transparent BIPV-modules with new design features, Conference on Advanced Building Skins 2019 (Session C3), Bern (publica.fraunhofer.de)

- J. Eisenlohr et al., Methodology and tool for the electrical layout of BIPV-modules with novel design features, 36th EU PVSEC (6DO.8.5), Marseille

- T. E. Kuhn et al.: Neurartige, teiltransparente BIPV-Module mit erhöhtem Gestaltungsspielraum. Forum Bauwerkintegrierte Photovoltaik, 18.-19. März 2019, Bad Staffelstein (publica.fraunhofer.de)