| Duration: | 10/2018 - 9/2020 |

| Contracting Authority/ Sponsors: | Bundesministerium für Wirtschaft und Energie (BMWi) |

| Project Focus: |

CUT-A PLUS – Cutting Edge Characterization and Technology for the German PV Industry PLUS

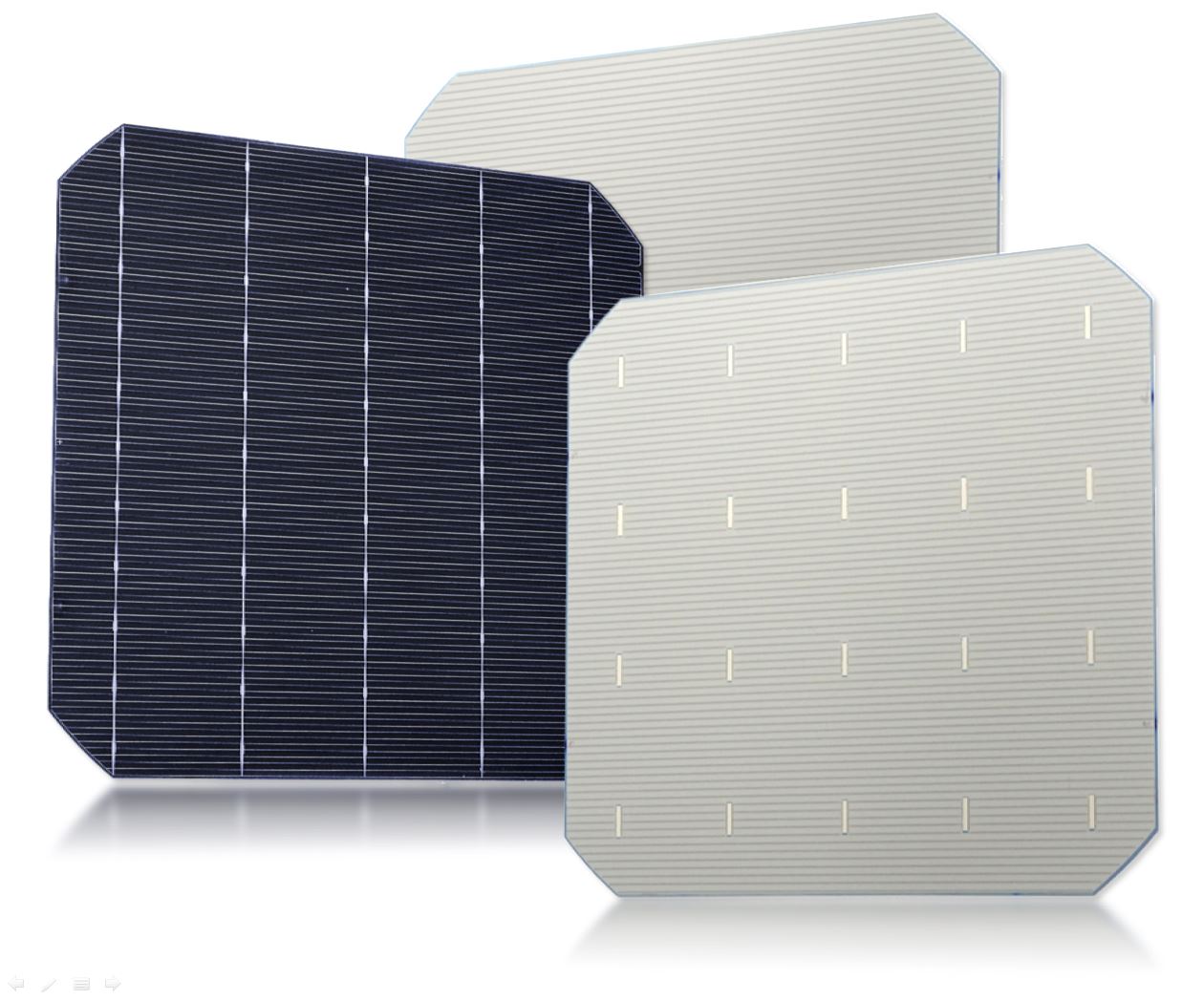

The project »CUT-A PLUS« is the follow-up project of the project »CUT-A«. In line with the previous project, the focus is on the further development of double-sided passivated PERC solar cells made of mono- and multicrystalline p-doped silicon. The technology for fabricating this meanwhile industrially predominant solar cell structure is being developed at the PV-TEC (Photovoltaic Technology Evaluation Center) of Fraunhofer ISE with a view to further increasing efficiency and is being transferred to the industry.

According to current estimates by market research institutes, the PERC technology will have the largest market share by 2025 and is currently being driven enormously in the photovoltaics industry as a key short- to medium-term technology. On the one hand, the project focuses on the modernization and expansion of the PV-TEC process platform and the further development of individual processes and, on the other hand, on the further development of the overall process through the regular fabrication of PERC solar cells.

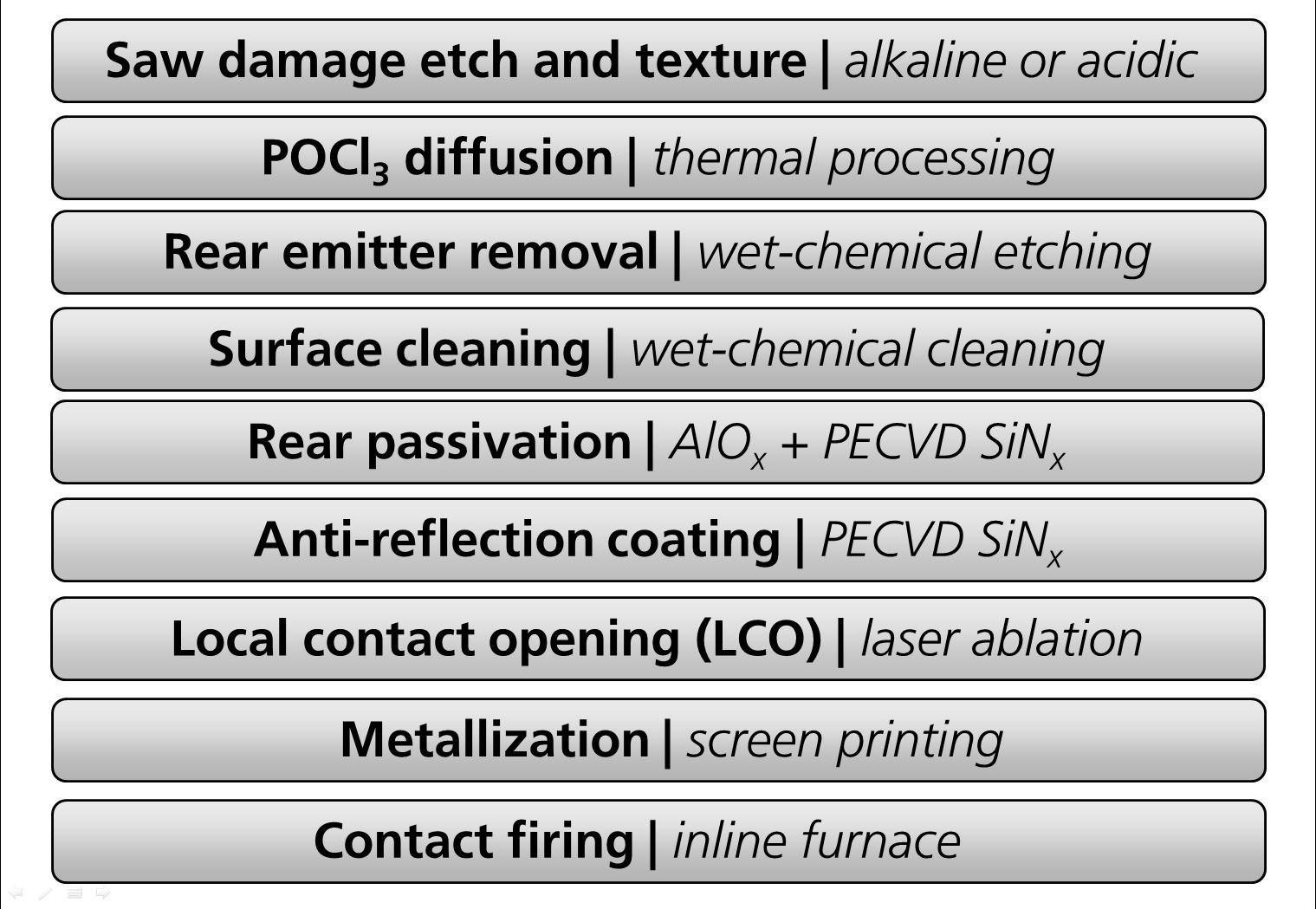

The central aim of the follow-up project "CUT-A PLUS" is to re-establish and further develop the standard process route for mono- and multicrystalline PERC solar cells in the re- and newly established PV-TEC laboratories. This includes the integration of new processes at the new tools into an overall process, the re-establishment of a high-quality basic overall process sequence for PERC cells and then the increase in efficiency to 20.5% (multicrystalline) or 22% (monocrystalline), the manufacture of partial solar cells (e.g. half solar cells) and the manufacture of demonstrator modules. In addition, the industrial deactivation of light-induced degradation will be integrated into the overall process and further optimized. An overall production process for monocrystalline solar cells with selective emitter is also to be established and a peak efficiency of 22.5% is to be demonstrated. As in "CUT-A", the regular fabrication of PERC solar cells is essential to ensure that the development of the overall process can continue effectively in the future and that industrial enquiries can still be coupled organizationally.

In addition to the further development of the PERC technology, which then permits higher efficiencies of solar cells, the possibility for German companies to conduct research and development in Germany with the existing facilities, processes and infrastructure will be improved. Particularly in view of the stagnating PV production in Germany, the focus is additionally shifting to internationally very successful PV tools and machine builders. Therefore, the PV-TEC of Fraunhofer ISE can be an essential component if the PERC standard process is maintained at the highest level.

The previous project "CUT-A" also focused on the further development of double-sided passivated PERC solar cells made of mono- and multicrystalline p-type silicon. |