| Duration: | 12/2019 - 11/2022 |

| Contracting Authority/ Sponsors: |

Bundesministerium für Wirtschaft und Energie (BMWi) |

| Project Partners:: | Fraunhofer CSP (Konsortialpartner); pi4_robotics (Konsortialpartner); Wavelabs Solar Metrology Systems (Konsortialpartner); Aluminium Feron (Partner im Unterauftrag); CE Cell Engineering (Partner im Unterauftrag); DENKweit (Partner im Unterauftrag); Temicon (Partner im Unterauftrag); Heckert Solar (Partner im Unterauftrag); Sunset Energietechnik (Partner im Unterauftrag); Ulbrich of Austria (assoziierter Partner) |

| Project Focus: |

CTS1000+ - More Energy per Cell Power - Holistic Cell-to-system Module Yield Increase

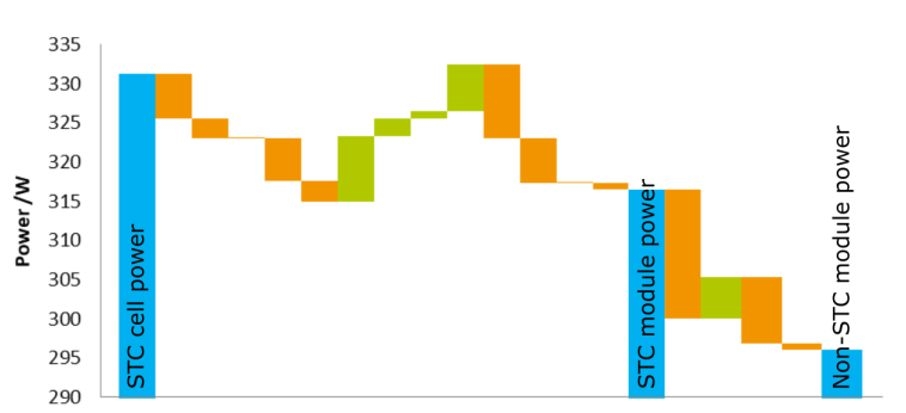

State-of-the-art methods are used to achieve maximum module performance from a given cell performance under laboratory conditions (Standard Testing Conditions STC). This optimization is an essential part of the product development for module manufacturers and suppliers in accordance with today's common evaluation of PV modules based on a specific price €/Wp. However, this consideration does not go far enough.

The research project "CTS1000+" takes the next decisive step from a module optimized under laboratory conditions to a module with an increased energy yield (kWh) per installed power (kWp): It extends the Cell-To-Module (CTM) consideration in the direction of the overall system (Cell-To-System (CTS)). In a second step, the financial side is added: Improvements are also evaluated in terms of costs. The goal of the sub-project and the overall project is to reduce the electricity production costs (€/kWh) and to increase the achieved yields (kWh/kWp) through optimized modules and components. Necessary steps for this are an understanding of the mechanisms at work, the development of simulation and analysis tools, component optimization, adaptation of the PV module, and the development and application of advanced characterization methods.

To this end, module materials, material combinations and module designs are to be implemented and characterized in detail using measurement technology in the subproject. Several topics are in the foreground for module optimization:

1. Optimization of the optical behavior of the module to increase the luminous efficacy.

2. Optimization of irradiation and ambient temperature management.

3. Adjustment of module topology, layer structure and module materials.

For comparability of solar modules, test conditions are defined for production and laboratory measurements (STC: 1000W/m², spectrum AM1.5, 25°C, vertical incidence of light). However, these are never present in real operation.

In the project, the yield of PV modules is therefore to be increased through holistic optimization. To this end, the focus of module performance optimization must be shifted from individual points in time and strictly defined operating conditions (e.g. laboratory tests at STC) to time series (annual data) and variable operating conditions (weather). Furthermore, modules and components are further developed so that an increase in module performance under real operating conditions is achieved. This will be qualified and quantified by experiment and simulation.

An adaptation to realistic conditions enables a significant cost reduction. For this purpose, the analysis of the module-internal power losses based on the cell-to-module methodology (CTM) as used in the predecessor project CTM100+ project will be extended and carried out for each operating time during the course of the year.

At the same time, the characterization technique is being improved to provide relevant results beyond standard conditions. Realistic module characterization at different light incidence angles is being further developed for solar simulators and other measurement systems. Optimizations of the module components are derived from the analysis and modeling, which enable an increase in yield. Optimizations are based on the module yield and not on the power losses assigned to the individual components (holistic approach).

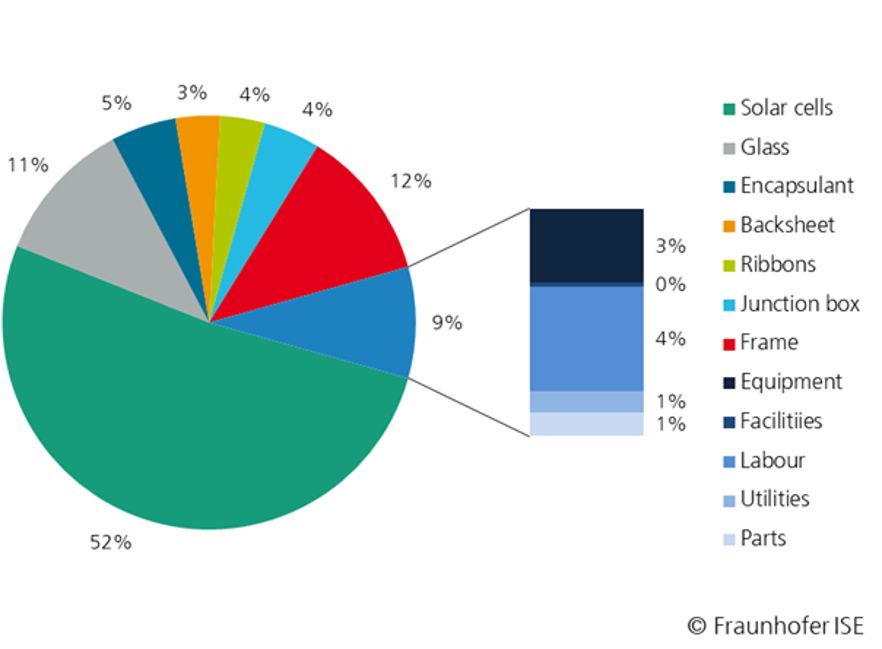

In addition, the costs of the adapted components are taken into account to enable a reduction in specific costs (€/kWh). Further cost reductions result from an optimization of the manufacturing process for modules.

Specific project objectives in the subproject:

a) Module yield increase by variation of the solar cell

b) Optimized reflection and emissivity of the back foil

c) Adjustment of the module front for improved coupling of light.

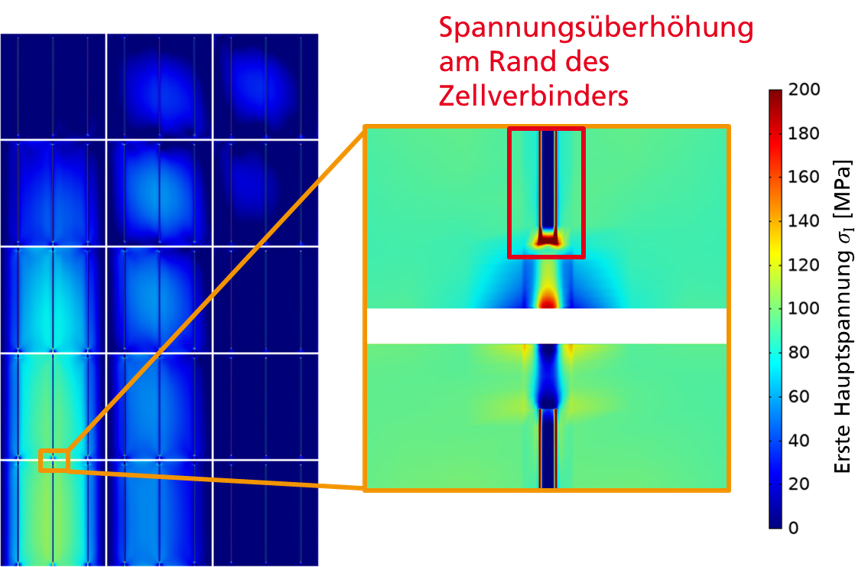

d) Optimization of the cell connector

e) Optimization of the cross-connection

f) Yield increase PV module

g) Development of optical characterization systems

h) Extension of the forecasting models for module yield and costs.

i) Process optimization in module production.