| Duration: | April 2016 - June 2019 |

| Contracting Authority/ Sponsors: | German Federal Ministry of Economic Affairs and Energy (BMWi) |

| Project Partners: | Fraunhofer CSP, Heckert Solar, SI Module, f|solar, Aluminium Féron, Wavelabs, Pi4 robotics, temicon, J.v.G. Thoma |

| Website: | www.cell-to-module.com |

| Project Focus: |

CTM 100+ – Improving Module Performance by Analysis of Cell-to-Module Losses with SmartCalc.CTM

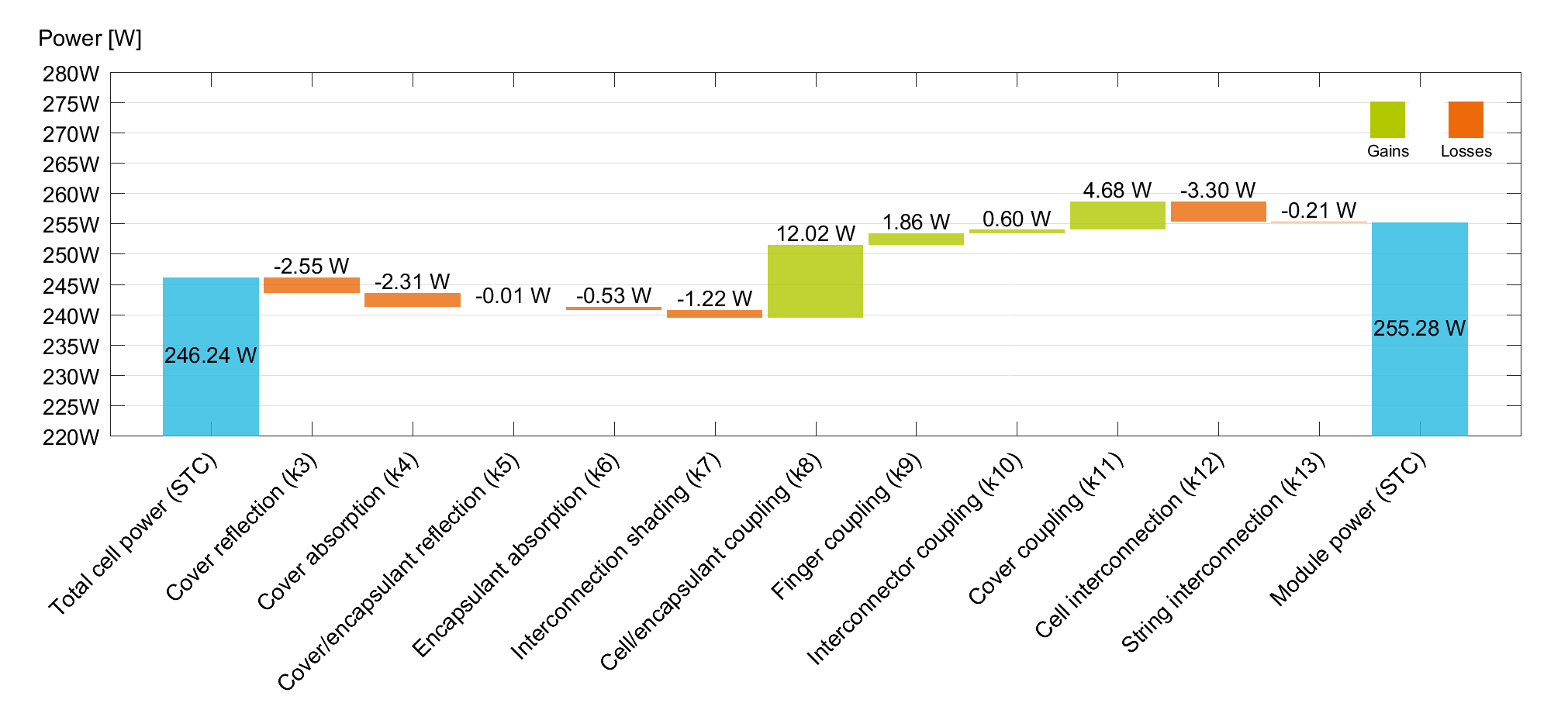

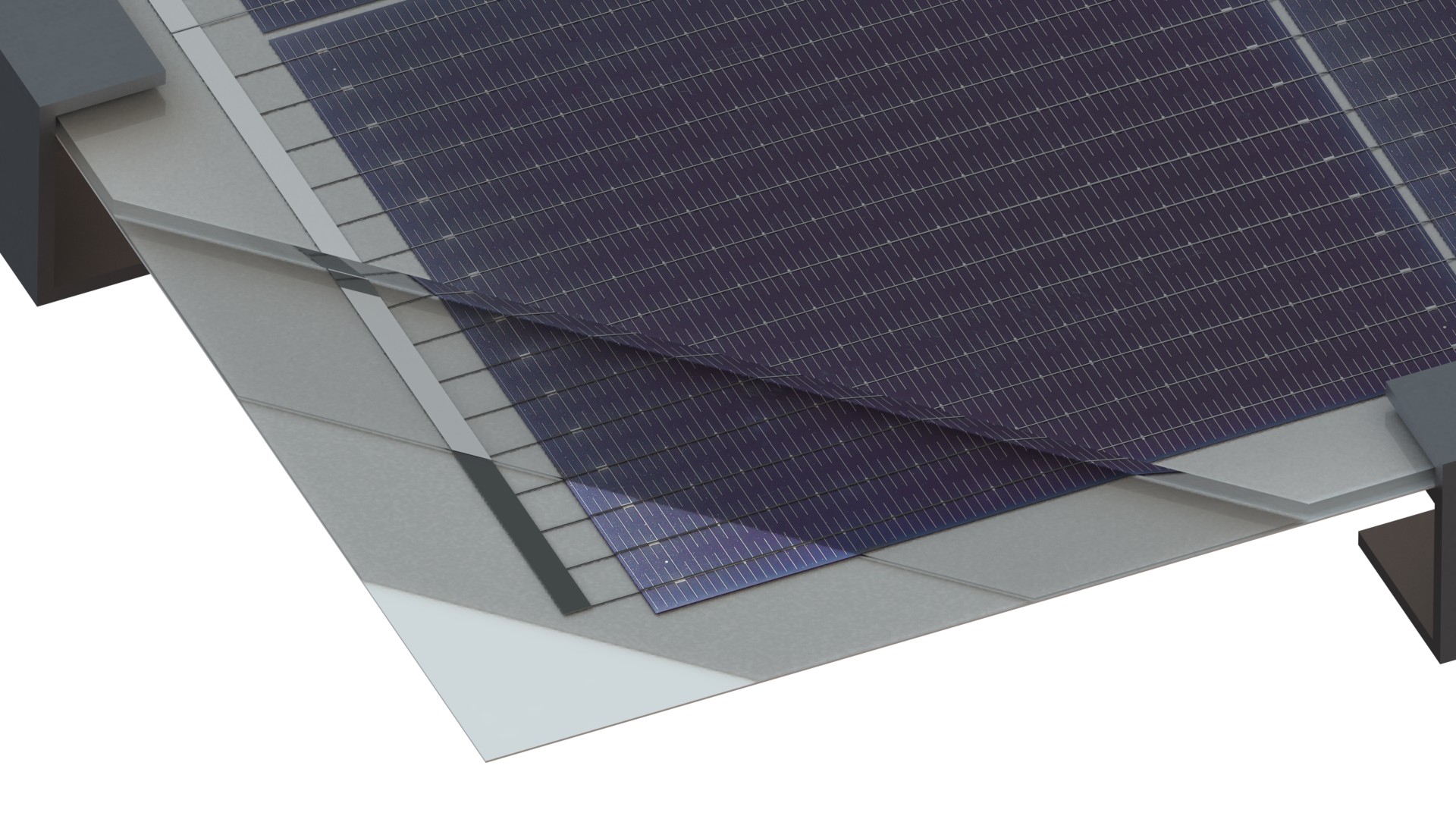

When integrating solar cells into a standard module, losses occur at optical, electrical, and inactive surfaces, but also optical coupling gains. For this reason, todays modules often feature a lower output than the sum of the individual cell outputs. The individual gain and loss mechanisms from cell to module are analyzed and purposefully optimized in the “CTM100+«” project. The objective is the development and production of modules, whose output under STC conditions is greater than the sum of the initial cell outputs: CTM>100 %. In cooperation with the project partners, industry-relevant module designs and materials are developed, analyzed, and realized in large-scale modules.

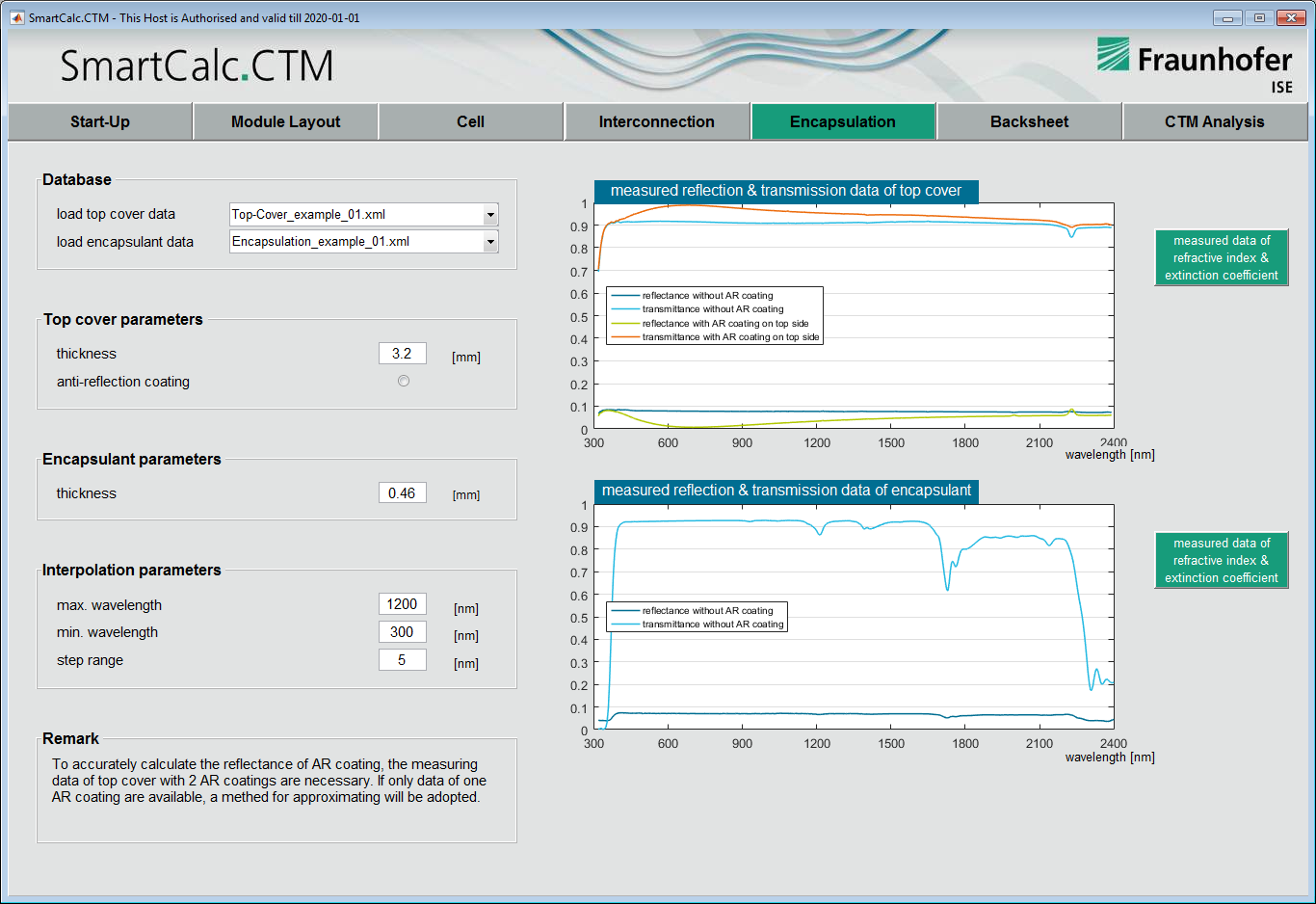

A system for measuring and calculating the individual gain and loss mechanisms developed at Fraunhofer ISE was used and further developed for the purposeful CTM analysis of different cell and module designs. The calculation models are implemented in a specially developed software “SmartCalc.CTM”. There, the optical and electrical properties of the different solar cells and module materials are stored there. This enables the simulation of conventional and new module setups prior to expensive prototyping in a module production line. The influence on module power of material properties can be assessed directly at the module level to produce glass, anti-reflective coatings, embedding films, cell connectors and backside films using “SmartCalc.CTM”.

Different module designs and solar cell types can be implemented and validated with the model: glass-glass modules as well as glass-film modules, AI-BSF standard solar cells with contact on both sides, PERC cells, hetero-junction and back contact-cells as well as metal-wrap-through (MTW) or interdigitated-back-contact (IBC) cells. 3, 4, or 5 busbars, wiring (multi busbar or SmartWire) are stored as wiring processes. Numerous characterization methods are available at Fraunhofer ISE for the determination of the relevant optical and electrical material properties.

For example, it was possible to produce half-cell modules with a CTM of 104 % (module output 256 W) or multi busbar modules with 306 W at ModuleTEC of Fraunhofer ISE with the aid of “SmartCalc.CTM”.