| Duration: | March 2017 - February 2020 |

| Contracting Authority/ Sponsors: | Federal Ministry for Economic Affairs and Energy (BMWi), PTJ Forschungszentrum Jülich, AZUR SPACE Solar Power |

| Project Partners | AZUR SPACE Solar Power, ORAFOL Fresnel Optics |

| Website: | AZUR SPACE |

| Project Focus: |

CPVMod – CPV Module in Modular Design

Subproject: Module Design and Module Performance

The focus of the CPVMod research project is the development of innovative, high-performance concentrator photovoltaics (CPV) modules. The advantage of CPV modules is the concentration of sunlight onto highly efficient solar cells that are only a few square millimeters in size, thus saving semiconductor material. In addition, the modules achieve conversion efficiencies of more than 30%. The modules developed as part of the CPVMod project are to be produced using cost-effective and robust manufacturing technologies. These manufacturing technologies are intended to enable reliable module production also in the vicinity of future CPV installation sites with a high regional value-added share. The technology is particularly suitable for areas in the Earth's sun belt with a high proportion of direct sunlight.

In the subproject "CPV Module in Modular Design: Module Design and Module Performance", the module design is being evaluated and further developed by Fraunhofer ISE in cooperation with the project partners AZUR SPACE and ORAFOL. Besides a high electrical efficiency, the focus of the module design is on the production technology to be used based on simple methods for quality assurance. A further project aim is the examination of the components and the module for long-term stability and the evaluation of the module output power under external conditions.

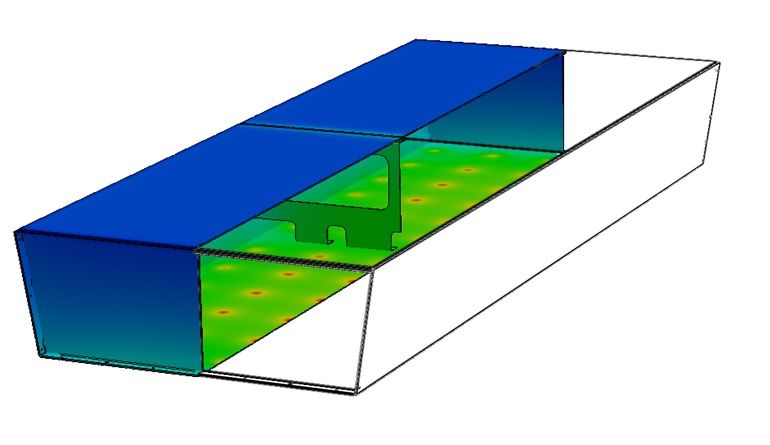

Figure 1 shows AZUR C3PV modules mounted on solar tracking units at Fraunhofer ISE. In standardized outdoor measurements at Fraunhofer ISE, the C3PV modules reached an electrical module output power of 440 W and efficiencies of 32 %. The C3PV modules consist of arrays with Fresnel lenses and Enhanced Fresnel Assemblies (EFA) mounted in a metal trough. The metal trough serves as an efficient heat distributor and thus for passive cooling of the solar cells. Due to the concentration of sunlight by the Fresnel lenses, not only electrical energy but also considerable amounts of heat are generated in the solar cells. This heat must be sufficiently redistributed in the CPV module to prevent electrical losses due to increased temperature. The temperature differences within the CPV modules were determined in the CPVMod project using thermal finite element simulations (FEM). Figure 2 shows the heat distribution within the CPV module. As expected, the highest temperatures occur in the solar cells, but in a range typical for CPV modules.

In the next step, in order to evaluate these temperature differences, thermo-mechanical FEM simulations were performed. So far, neither significant mechanical loads in the module nor critical displacement of the solar cell position could be determined. A sufficient redistribution of the thermal energy in the module is therefore guaranteed.

Another focus of the project is the investigation of the long-term stability of the module through accelerated ageing. For this purpose, various test sequences were carried out on module components and specially mounted samples. Prior and after the test, the samples are extensively characterized. For this purpose, samples are electrically measured but also the material is analyzed by tensile shear testing (see figure 3), mechanical load tests or ultrasonic microscopy. With the experimental investigation new materials and processes are evaluated.