| Duration: | 01/2019 - 12/2023 |

| Contracting Authority/ Sponsors: |

Fraunhofer-Gesellschaft |

| Project Partners: | Fraunhofer ISE, IEE, ISI und IEG als Kerninstitute; Assoziierte Fraunhofer-Institute: UMSICHT, IOSB, SIT, IPA, IBP, ICT |

| Website: | Fraunhofer CINES |

| Project Focus: |

Development of novel cell and stack designs for PEM electrolyzers as part of the Fraunhofer Cluster of Excellence Integrated Energy Systems CINES

One of the main technical solutions for the transformation of the energy system is hydrogen production by water electrolysis, which makes it possible to convert electrical energy from volatile, renewable energy sources into a storable form of energy which can be used according to the demand in downstream applications.

In cooperation with our partner institutes Fraunhofer ICT and Fraunhofer UMSICHT, we are developing novel materials, components and cell concepts for proton conducting membrane electrolysis, which uses an acidic membrane (PEM: polymer electrolyte membrane) as electrolyte.

We focus on the following research areas:

- Synthesis of cost-optimized catalysts for the cathode and anode with the aim of either partial or complete substitution of precious metals.

- Manufacturing of membrane electrode assemblies (MEA) with structured electrodes in a direct printing process and implementation of a catalytically active recombination layer to improve gas quality.

- Proof-of-concept of a novel frameless cell concept to simplify cell construction and reduce costs by applying automated manufacturing processes.

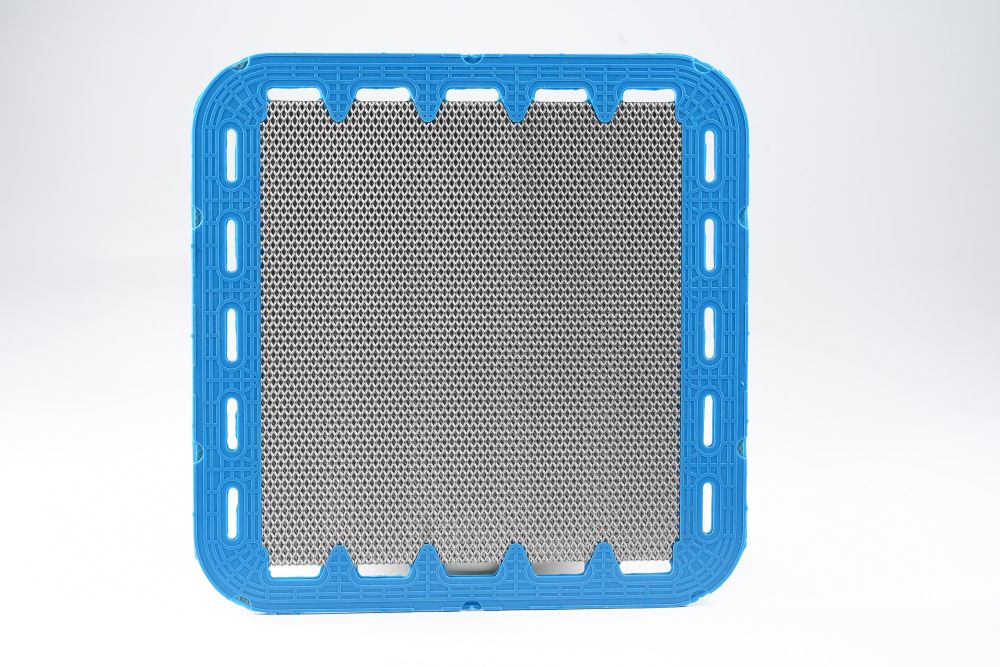

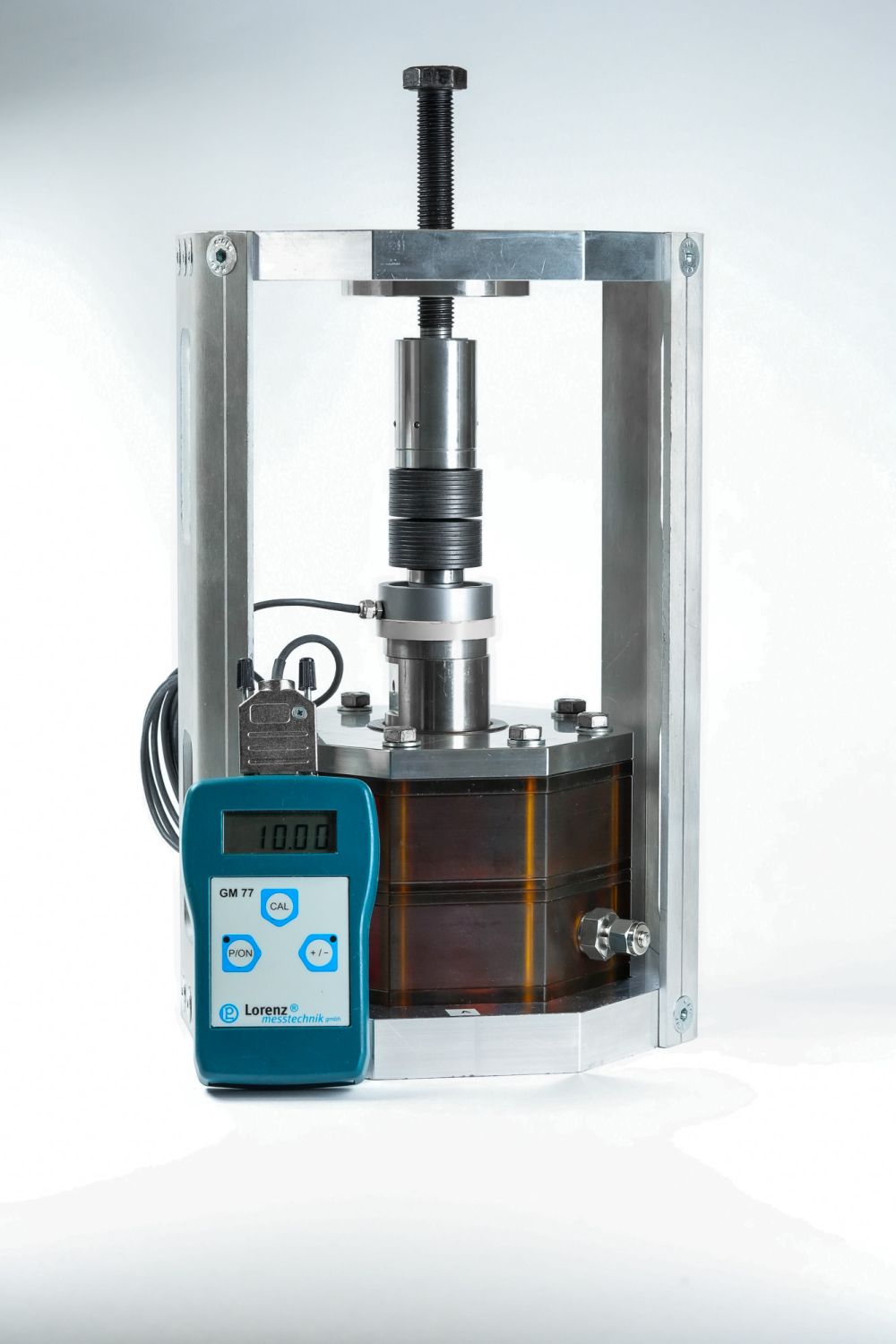

To develop the proof-of-concept of a frameless PEM water electrolytic cell, different designs and manufacturing approaches of the half-cell compounds were performed to date on the base of an issued patent (DE 10 2013 225 159). This half-cell compound combines the functionalities of a classic flow field, porous transport layer and seals with manifolds in one component, so that automated manufacturing processes can be used perspectively. The compound consists of one or more metallic base elements, such as expanded metals or felts which serve as porous transport layer, and polymeric filler material for sealing and forming the inflow and outflow areas. For this purpose, extensive screening was carried out to select suitable material combinations of various thermoplastics and elastomers with regard to their durability, sealing and incorporation into porous metallic structures. To build a single cell of the novel cell design, the original concept was further developed to reduce the number of sealing interfaces. At the same time, new sealing structures were developed to significantly reduce the necessary external clamping pressure. The full cell constructed in this way is gas-tight up to 10 bar and was successfully tested with a reference MEA. Compared to measurements with an established standard laboratory cell, the cell concept developed in CINES performs equally well or even better.

The goal of our work in the first three years is a demonstrator stack for PEM water electrolysis with a cell area of 150 cm², in which all new materials and components are integrated. This demonstrator is then to be commercialized with industrial partners.