| Duration: | August 2013 - July 2016 |

| Contracting Authority/ Sponsors: | German Federal Ministry of Education and Research (BMBF) |

| Project Partners: | VARTA Storage GmbH, MSB Elektronik und Gerätebau GmbH, University of Technology and Economics Allen |

| Project Focus: |

Cell Booster – Simulation, Development and Setup of a High-Efficiency DC/DC Converter Concept for Small Battery Units

Electric storage units, which can compensate differences between generation and consumption, are very important for the expansion of renewable energy usage. Storage solutions are also needed in off-grid electricity systems and to operate electric vehicles. As battery cells have a low cell voltage, the voltage must be adapted for the intended application. In battery packs, higher voltages are achieved by hard-wired series connection of the single cells. Here, the weakest cell limits the performance of all cells and one defective cell renders the whole battery pack unusable. A modular concept combined with intelligent power electronics can minimize these disadvantages. This leads to very reliable systems with low maintenance costs.

When developing a battery storage system, different battery voltages can be obtained by hard wiring the single cells in series. However, the direct connection of battery cells in conventional systems is often the main cause of accelerated battery aging, which is accompanied by declining system efficiency and increasing maintenance costs. It is also disadvantageous that a defect in a single cell results in a failure of the entire storage unit. Production of the battery pack is complicated, as is the replacement of a defective single cell. This also leads to system losses, as the substitute cell cannot be fully exploited due to aging processes in the other cells.

Within the “Cell-Booster” project, a new technological approach is being investigated, which optimizes the energy and cost efficiency of current battery storage systems and should extend their operating time and service life. The intended innovation addresses the system technology, with focus on novel embedded electronics, the so-called “Cell Booster”. These power electronics are responsible for direct impedance matching and DC/DC conversion, which decouples the 48 V battery pack. Battery pack and DC/DC converter form a module. The number of modules is variable enabling the realization of storage systems with different capacities.

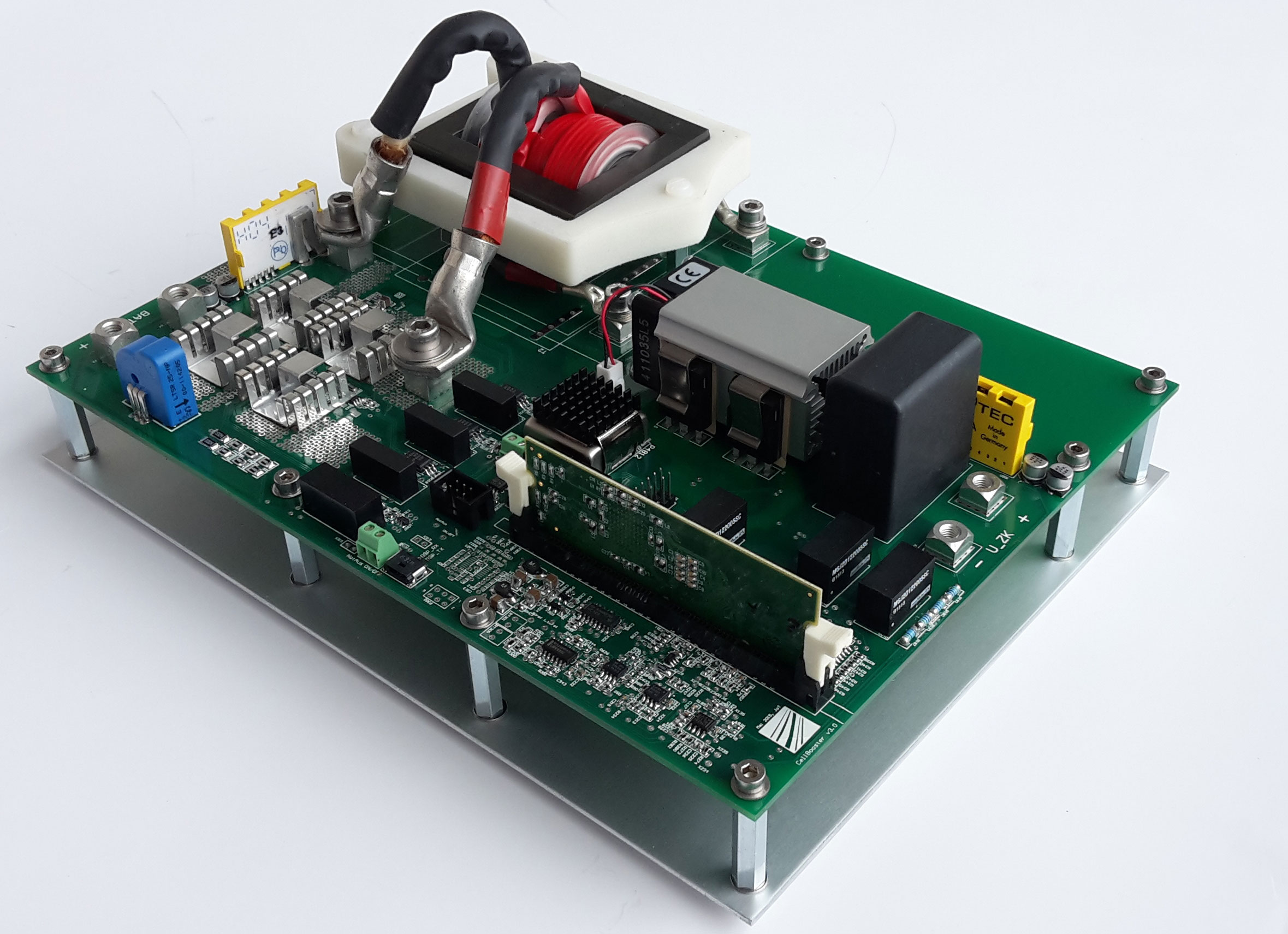

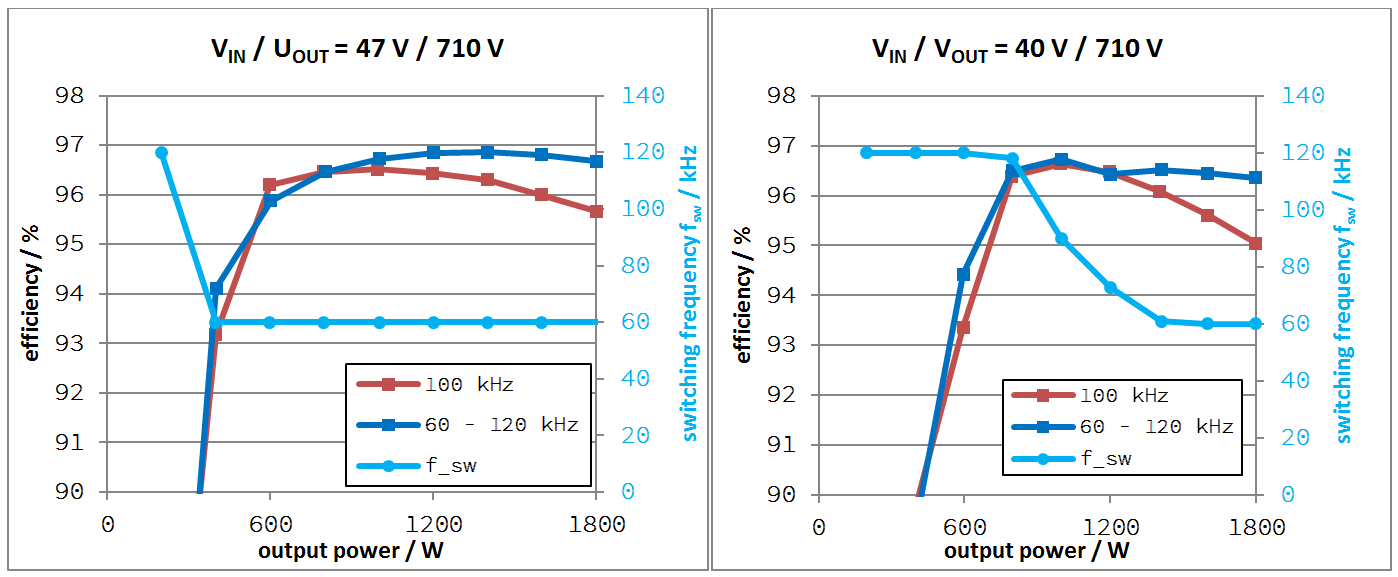

Maintenance of the system is simple, as individual modules can be replaced even during operation. Due to decoupling of the modules, a module with a defective cell can easily be replaced by a battery pack of the most recent generation with completely different properties. This ensures a high service life of the system and enables the construction of hybrid systems, which combine the advantages of different battery technologies in one system. The power electronics unit was developed at Fraunhofer ISE. In addition to a compact design, attention was paid to a high degree of efficiency in the partial load range. To achieve a high degree of efficiency in the laboratory prototype (fig, 1), different transistor modulation types were implemented and power-based switching frequency adjusted developed (fig. 2).

The “Cell Booster – Simulation, Development and Setup of a High-efficiency DC/DC Converter Concept for Small Battery Units” project is part of the “DC/DC Converter Concepts for the Efficient and Modular Connection of Battery Units at the High Voltage Input of Inverters” project.