| Duration: | 03/2019 - 03/2023 |

| Contracting Authority / Sponsors: |

The project is carried out within the framework of the BMBF funding measure "CLIENT II". |

| Project Partners: | Karlsruhe Institute of Technology KIT, Geothermie Neubrandenburg GTN, SolarSpring, Fraunhofer Chile Research CSET, Centro de Excelencia en Geotermia de los Andes CEGA, Transmark Ltd, GTN LA |

| Project Focus: |

BrineMine – Extraction of Valuable Materials and Drinking Water from Geothermal Springs in Chile

Recent geopolitical developments show the urgency of securing new ways of accessing raw materials relevant to economic strategy and making their extraction much more sustainable. The extraction of minerals such as lithium, magnesium, potassium, boron or gold from geothermal brines is not trivial in terms of process technology, but it is certainly possible. In addition, fresh water can be extracted from brines using geothermal energy as an energy source, which can be an important added value especially in arid regions. The aim of the project is, on the one hand, to determine the potential for mineral extraction from geothermal brines in Chile and, on the other hand, to develop and test the process engineering equipment for their extraction as well as for water production.

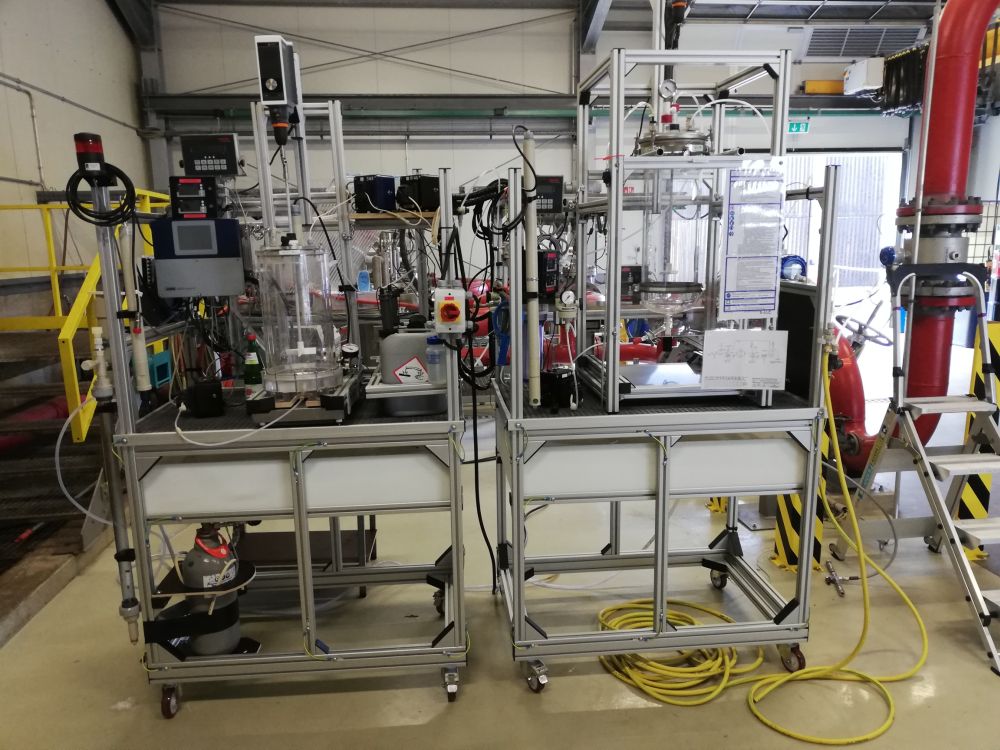

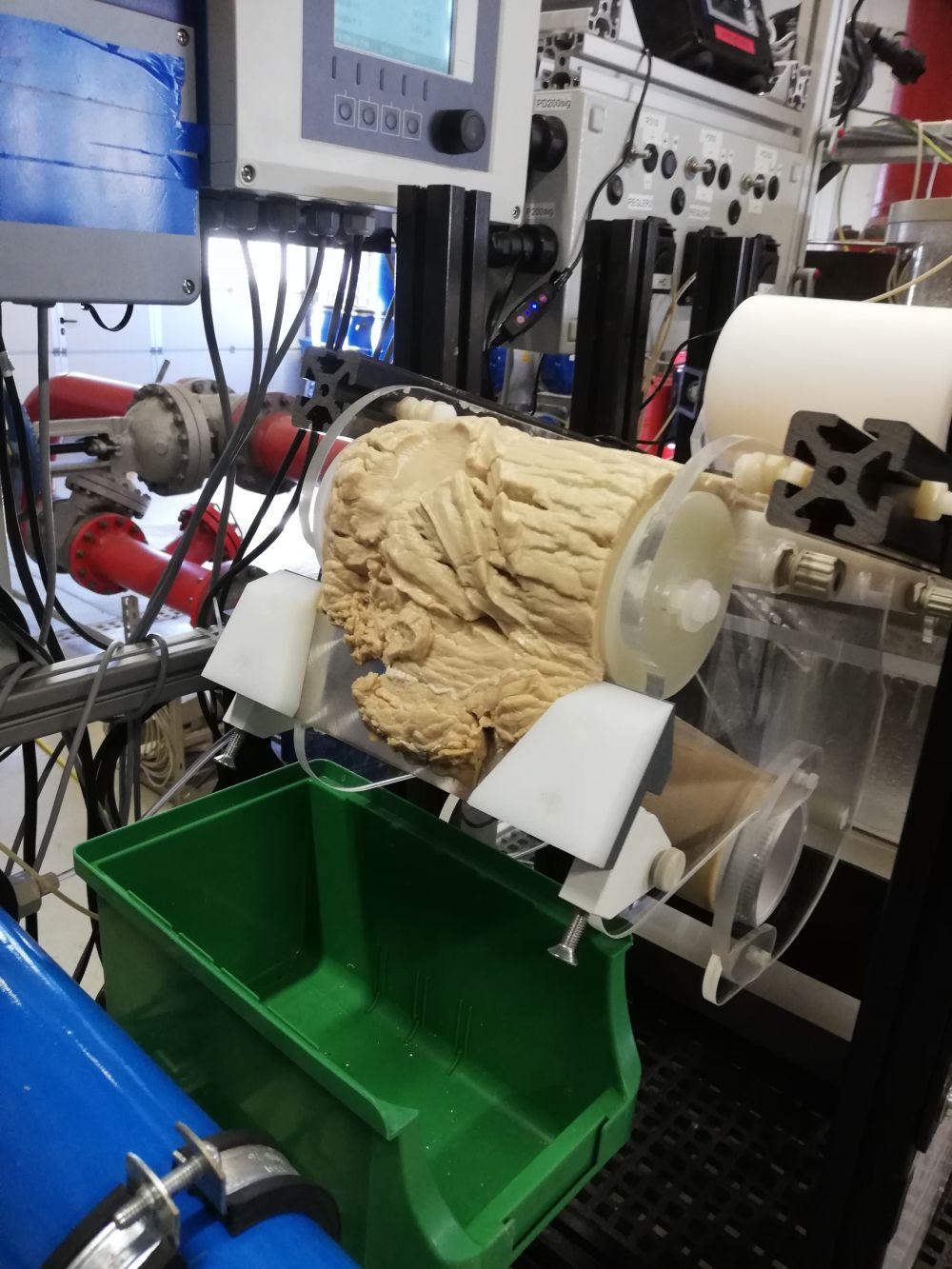

The BrineMine project is a 4-year research project between German and Chilean research and industrial partners. The aim of the project is the development and research of a technology for the extraction of valuable minerals and fresh water from geothermal brines. In Chile, numerous geothermal springs are known to have e.g. magnesium contents of > 0.5 g/l, potassium contents of > 1.7 g/l, borate contents of > 0.1 g/l or lithium contents of > 0.6 g/l. Current water analyses are incomplete and several other potentially valuable metals have not yet been analyzed. To this end, BrineMine is exploring and analyzing geothermal wells in Chile to assess the overall techno-economic recovery. In Germany, too, there is now a great deal of interest in extracting lithium from geothermal brines, e.g. in the Upper Rhine Graben, where up to 0.16 g of lithium per liter can be found. The technological approach in the project is mainly based on the use of chemical precipitation, filtration as well as innovative membrane processes. While the pre-concentration of the brine is done by pressure-driven reverse osmosis (RO), the further concentration up to saturation is done by membrane distillation (MD). Here, the geothermal heat extracted before the RO process is used as the driving energy for the MD process. The main technical challenges to be solved are to be able to carry out the crystallization of the various solutes such as silicates and calcites occurring during the flashing and cooling of the brine in a controlled manner by chemical precipitation and filtration and to avoid deposition on the RO and MD membranes. Therefore, the investigations on scaling behavior as well as the development of methods to avoid it are the main research focus of the project. Initial investigations of the entire technology were carried out first with artificial brines and then with real brines in the Fraunhofer ISE laboratory. Based on the results, two demonstration plants were developed and built, which were tested in a geothermal power plant of Pfalzwerke geofuture GmbH in Insheim 2021. A third demonstration system was subsequently installed and tested at a geothermal well in Puyehue, Chile. The results show that with the developed process chain a concentration of the brine is possible to the extent that a subsequent lithium precipitation can take place.