| Duration: | November 2016 - January 2020 |

| Contracting Authority/ Sponsors: | Federal Ministry for Economic Affairs and Energy (BMWi) via Solar-era.net |

| Project Partners: | IQE (Koordinator), FullsunPV (Unterauftrag IQE), Universidad Politecnica de Madrid UPM, Cyprus University (Assoziierter Partner) |

| Project Focus: |

ALCHEMI – A Low Cost, High Efficiency, Optoelectronic HCPV Module for 1000 Sun Operation

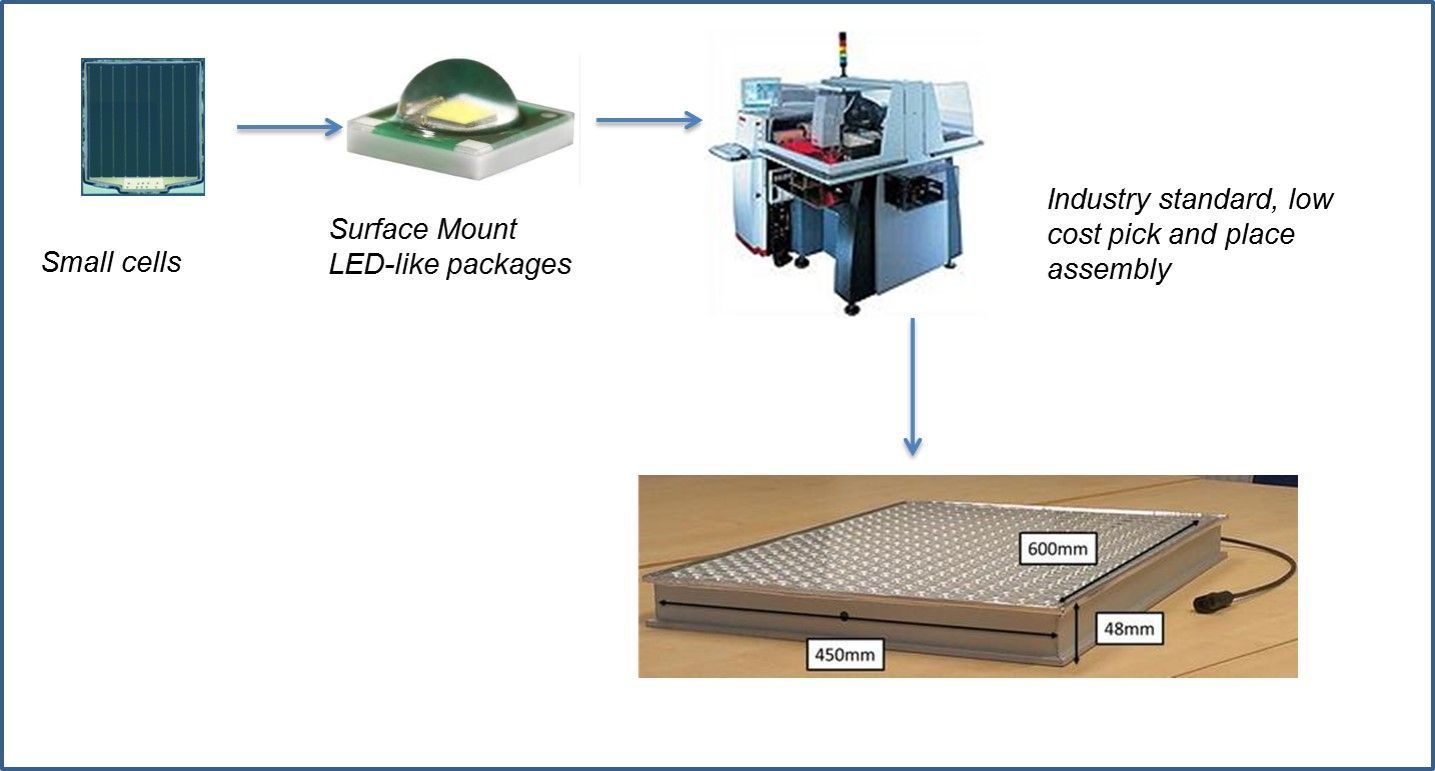

In (highly) concentrating photovoltaics ((H)CPV), solar radiation is focused on small but highly efficient solar cells, resulting in high overall efficiencies. Increased efficiency and cost-effective production technologies contribute to further costs reductions.

In the ALCHEMI project, a HCPV module is to be developed within a European consortium with central components (primary optics, cell) potentially being provided by German suppliers. The secondary optics are manufactured through procedures established in optoelectronics. Fraunhofer ISE optimizes the design of the two-stage concentrator optics and characterizes the prototypes. The thermal design is also being assessed by Fraunhofer ISE.

During the ALCHEMI project, the efficiency of this HCPV technology is to be further increased while reducing the costs through industrial manufacturing processes. The approach pursued in this project is to produce cost-efficient HCPV modules with high efficiency using established manufacturing processes from the LED industry and optoelectronics, thus achieving a reduction of the power generation costs using HCPV.

For optics design and thermal management, this means adjusting the design to the suitable materials, the dimensions and other framework conditions applicable in these manufacturing processes.

The overall optimization of the module is crucial for achieving highest efficiencies. The individual components of the solar cell, the optics and of the electrical contacting/bonding as well as the entire module design, e.g. the interconnection and heat dissipation, must be well adjusted to each other.

The goal of the (partial) project at hand at Fraunhofer ISE is the design and characterization of a two-stage concentrator optics for new HCPV modules. It is composed of refractive optics consisting of a silicone-on-glass (SOG) Fresnel lens as primary optical element (POE) and a secondary optical element (SOE) made from transparent silicone which is to be molded directly onto the cell.

The design is optimised using ray tracing with the goal of minimizing the focal length of the POE while maintaining high optical efficiency in order to achieve a low construction height with low weight and low cost of materials. Furthermore, the SOE design is intended to homogenize the radiation of the cell while ensuring a high acceptance angle of the entire optics. Overall, the design takes the framework conditions of the industrial feasibility into account (“designed for manufacture”). Fraunhofer ISE also supports module design through investigations of thermal management with the aim of optimizing heat dissipation, minimizing the operating temperatures of the cells and securing reliability.