| Duration: | May 2013 - April 2017 |

| Contracting Authority/ Sponsors: | German Federal Ministry of Economic Affairs and Energy (BMWi) |

| Project Partners: | Stiebel Eltron, SorTech AG, Fraunhofer IFAM |

| Project Focus: |

ADOSO – Gas Adsorption Heat Pump with a Crystalline Zeolite Heat Exchanger and a Novel Evaporator-condenser Device

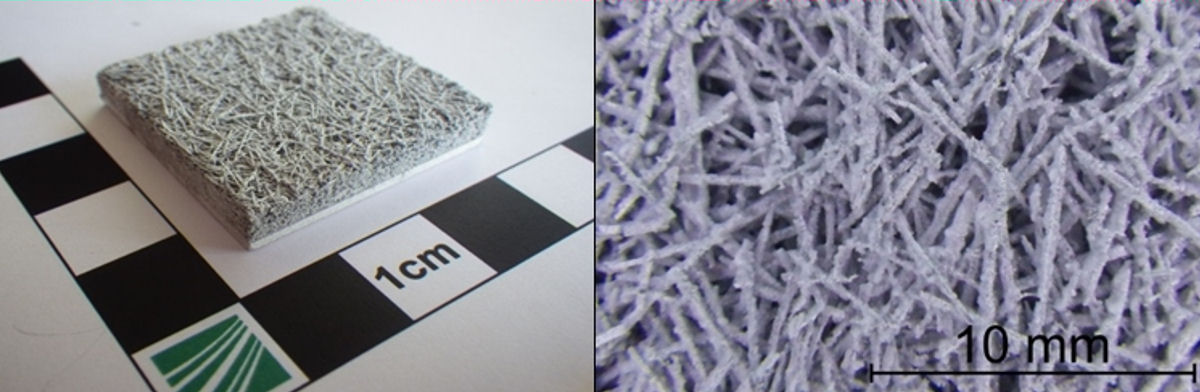

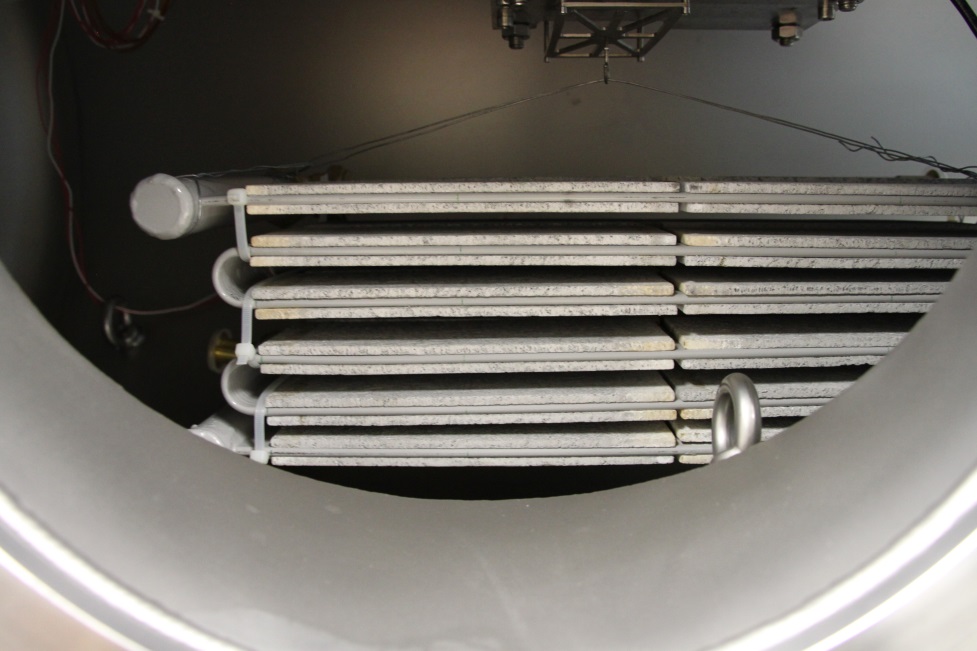

The objective is the development of a heater on zeolite basis with water as operating medium, which based on novel absorption heat exchangers and optimized functionality of evaporator and condenser is significantly more compact and cost-effective than the devices on the market with comparable outputs and an annual COP of over 1.3. Porous materials with good thermal conductivity are of central importance for the development of absorption heat exchangers. A large surface paired with thin sorbent layers (< 100 µm) accelerates the dynamics of the ad- and desorption process. It thus offers a larger potential for a higher power density of the sorption module of the gas heat pump.

Sintered aluminum fibers with a large specific surface (> 20 m2/m3) form the starting point for the development of heat exchangers with high power density. Fraunhofer IFAM developed a sintering process for this purpose that enables direct sintering of metal fibers with a metallic carrier. The metal structures are coated via consumptive growing of zeolite on the metal surface (SorTech AG). Fraunhofer ISE uses simulations with different detailed depths to compare different development variants already prior to their implementation. The coupled calculation of thermal and mass transport is considered in the design of adsorption heat exchangers. Yearly simulations at the system level provide annual COPs, which can be used for the suitability of newly developed devices for different markets and regions. The evaporator/condenser unit of the sorption module is also optimized regarding process dynamics. Porous structures are investigated for this component as well. First measurements show that by replacing the previously used fins with the newly developed fiber heat exchangers, the power density of the adsorption module can be doubled without reducing efficiency. Besides that, work for Annex 43 “Fuel driven heat pumps” of the heat pump program of the International Energy Agency (IEA) is performed, which is led by Fraunhofer ISE.

Here you can find further information about the ADOSO project:

"Doubling power density with metal fibers" (News of the BINE Information Service) [bine.info]