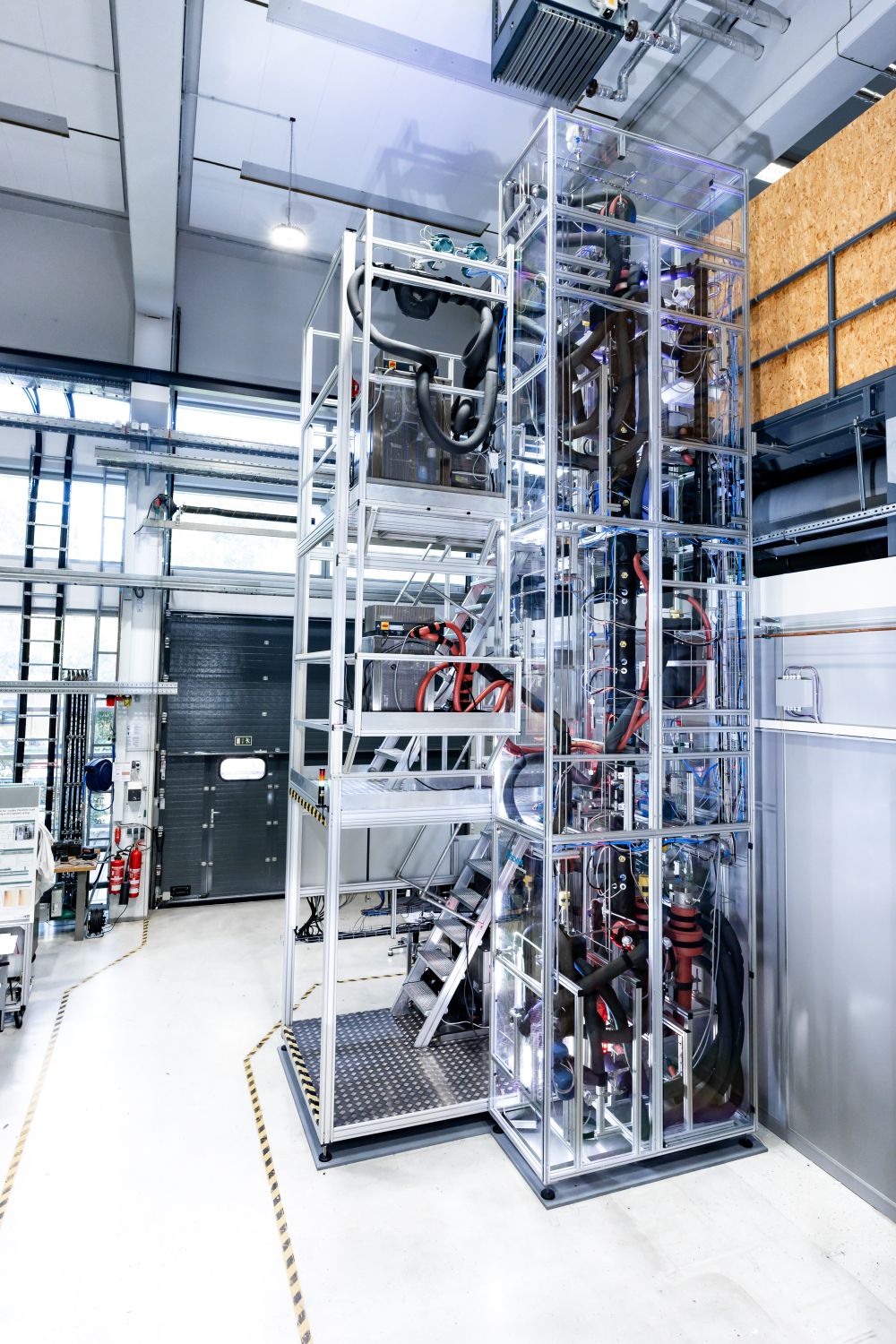

The versatile pressure and vacuum column from ILUDEST® enables detailed investigations and process development for distillation, rectification, absorption, reactive distillation, and extraction. The column can be equipped with various industry-standard structured packings or random packings to provide ideal industry-relevant conditions for your process.

Typical application areas for the column:

- reactive distillation using commercial catalyst packings (Power-to-MEDME project)

- various distillation processes for the production of sustainable jet fuels (SAFari project)

- purification of biogenic feedstocks and synthetic fuels such as methanol, DME, oxymethylene ether, gasoline, ethanol, and kerosene

- separation of valuable products (e.g., CO2) from waste gases using absorption

Operation:

Continuous evaporation of the medium in the column sump and condensation in the head of the column result in a thermal separation of the fed material mixture on the separation packings in the column.