The following tests for long-term stability are carried out in our TestLab PV Modules:

Durability

Tests for PV Module Certification

- Thermal cycling test

In this thermal load test, the temperature is alternated in two hundred cycles from -40°C to +85°C. This results in major thermal stresses in the module. - Humidity / frost test

The humidity-frost test is used to determine the extent to which a module can withstand the effects of moisture when undergoing changes in temperature from high positive temperatures to minus temperatures.

- Humidity / heat test

The test investigates the extent to which a module can withstand long-term exposure to moisture under hot conditions.

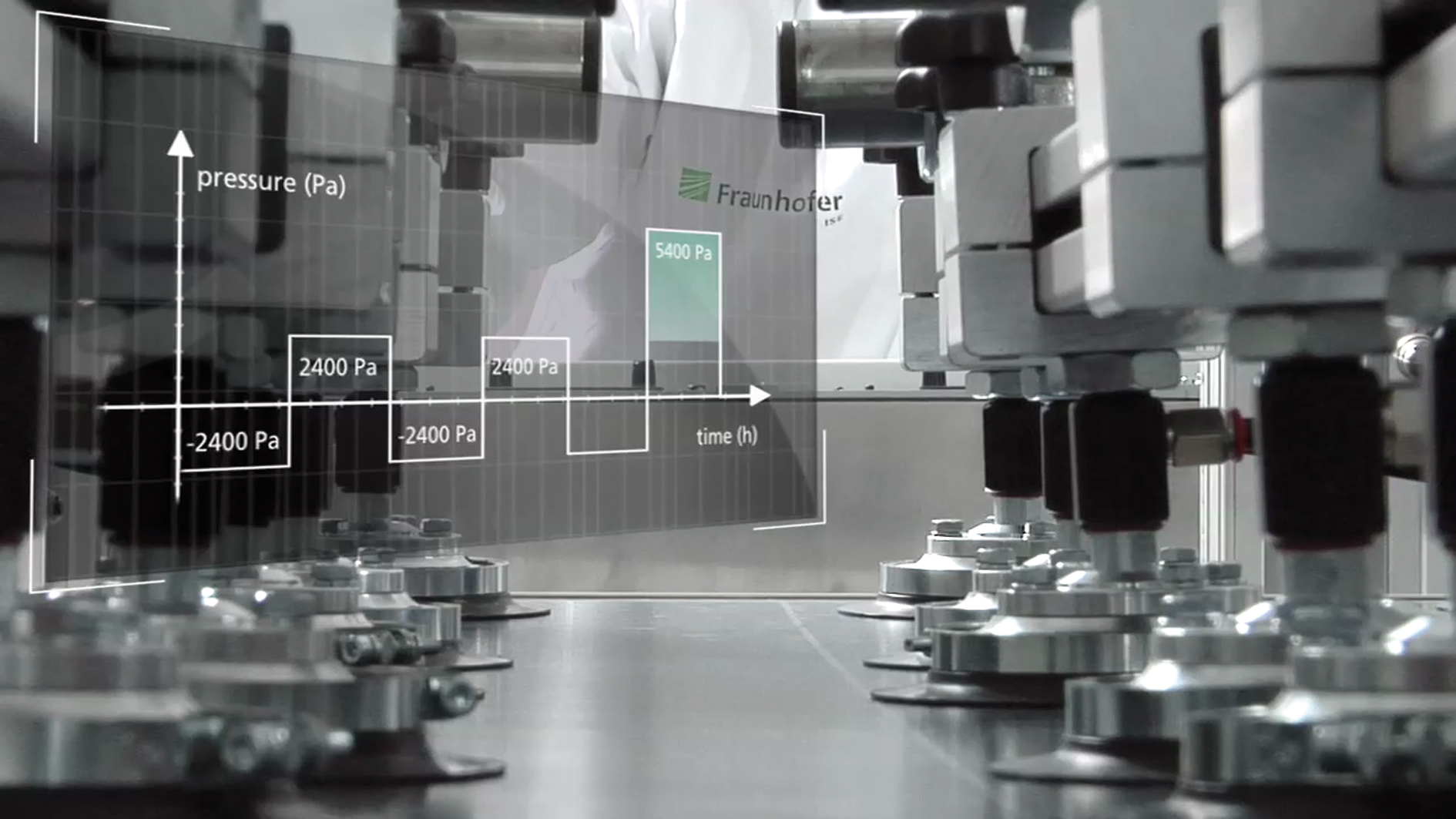

- Mechanical load test

In testing mechanical load-bearing capacity, a computer-controlled, homogenously alternating load is applied to the test specimen, and the resulting distortion is measured at the same time. This is done to simulate wind, snow and ice loads. Three cycles of two hours each are carried out, in which the front and rear are each subjected to a static load of 2400 Pascal. If the module is to be certified for increased snow and ice loads, the front is subjected to a load of 5400 Pascal during the final cycle.

- Hail test

A specially developed hailstone freezing technique is used to ensure that no air bubbles are trapped in the standard-sized spheres. The hailstones weigh exactly 7.5 g and have a diameter of 25 mm. With the aid of a special compressed air gun, the robustness of the module is determined by firing hailstones at defined, standardized target points (such as the conductor connection points).

- Hot spot testing

The hot spot endurance test is performed in a climate chamber with a solar simulator. Its purpose is to investigate whether or not a module is capable of withstanding the localized heating effects to which it might be exposed as a result of being in full or partial shade. The hot spot endurance test reveals the consequences of uneven cell properties if the module is shaded, whereby the worst-case shading scenario is identified using a specialized process. The hot spots are then identified with the aid of thermal imaging.