Press Release #15

Façade panels as heat sources for heat pumps

Heat pumps are currently seeing something of a boom in the heating technology market. However, not every property has sufficient space to accommodate the external air unit needed for an air-to-water heat pump. Where space is limited, new solar thermal façade panels could provide a noiseless and space-saving alternative, as well as an attractive architectural feature. As part of its ongoing TABSOLAR III research project, the Fraunhofer Institute for Solar Energy Systems ISE is developing and testing just such a solution in collaboration with industry partners. It will be presenting a demonstration façade showcasing its TABSOLAR® panels at the BAU trade fair, from April 17 to 22 at Messe München.

-

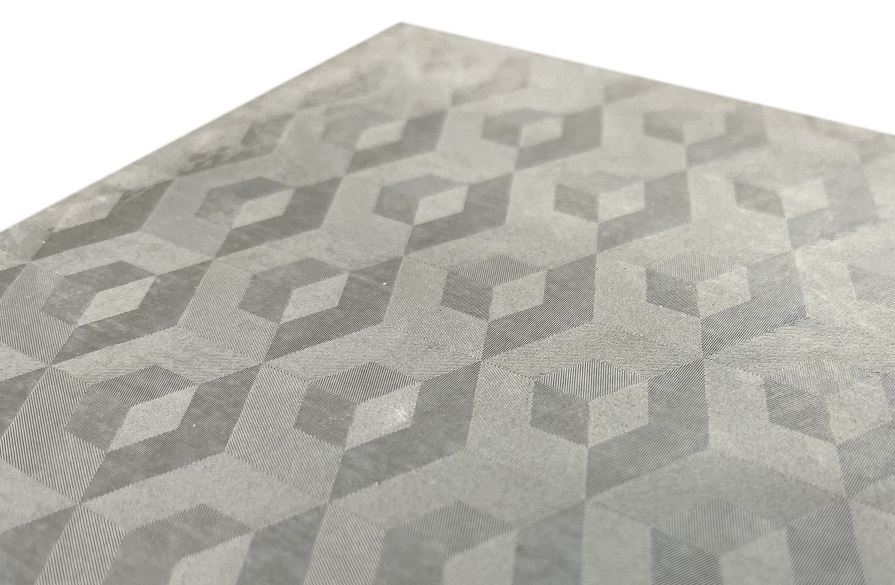

At BAU, the World's Leading Trade Fair for Architecture, Materials and Systems (April 17–22 at Messe München), Fraunhofer ISE (stand 528, hall C2) will be presenting a suspended rear-ventilated demonstration façade showcasing two hydraulically connected sample panels from its TABSOLAR®-Design range. Other samples will also be on display so that visitors can see the range of surface structures and a cross section through the channels.

The TABSOLAR® panels are brand new solar thermal components made from ultra-high performance concrete (UHPC). Available in a glazed or unglazed finish, they can be used to create an aesthetic architectural façade. Each panel is interspersed with channels containing a solar fluid, which absorbs the heat from the sun’s radiation and ambient air. This heat is then transferred via a heat exchanger into the heat pump circuit. The design of the channel structures is created using the bionic FracTherm® process developed by Fraunhofer ISE, which produces a multiple branched (or fractal) pattern similar to the veins found in leaves or the human body. Using this process, it is possible to create an evenly distributed network of channels across almost any shaped panel, which ensures uniform flow distribution and also a lower energy consumption rate for the pump. The panels themselves are made of ultra-high performance concrete using a membrane vacuum-forming process that is being further developed in cooperation with several industry and research partners as part of the TABSOLAR III project.

As low-temperature heat sources, the TABSOLAR® panels have the potential to provide a noiseless and attractive alternative to external air units for air-to-water heat pumps. “Our simulations suggest that both new builds and older retrofitted building stock would have sufficient façade space for this purpose,” explains Dr. Michael Herman, coordinator for the TABSOLAR III joint research project and project manager at Fraunhofer ISE. The unglazed variant (TABSOLAR® Design range) is intended as a heat source for heat pumps used for domestic hot water heating or swimming pools and, just like other UHPC façade panels available in the market, can be designed in different colors and with different surface structures. In contrast, the glazed panels with spectrally selective coatings (TABSOLAR® Premium range) can generate higher temperatures and are therefore designed to be used for domestic hot water heating and back-up heating in a similar way to conventional solar thermal collectors.

The prefabricated TABSOLAR® panels have been developed for suspended rear-ventilated façades (VHF), but there is potential to adapt the concept for composite exterior insulation and finish systems or sandwich wall systems in future. Moreover, the panels from the TABSOLAR® Heat & Cool range can be installed inside buildings as thermally activated building systems (TABS) for heating/cooling (including alongside conventional concrete core activation).

An interdisciplinary approach

The TABSOLAR III project has involved the relevant building trades at every stage in the development and testing of the new façade panels, from the initial preparations and planning through to manufacturing, installation and commissioning.

“Right from the outset, this has been an interdisciplinary project. We have pooled expertise from the relevant solar technology and construction sectors to develop an innovative and architecturally attractive solution which we hope will further the energy transition in the building industry,” explains Dr. Michael Herman. New software tools have also been developed for the planning phase, including an augmented reality app for visualizing the TABSOLAR® façades in-situ and an online configuration tool to aid the design process. Plus, plans are in place to ensure the technology can be integrated intoBuilding Information Modeling (BIM) processes. As the next step in the development process, the complete solution will now be prototyped in a demonstration façade and undergo practical testing and monitoring.

The TABSOLAR III research project is funded by the German Federal Ministry for Economic Affairs and Climate Action (BMWK) and builds on its predecessor projects TABSOLAR ( 03ET1117A/C/D) and TABSOLAR II ( 03ET1310A/B/C/D). The project is coordinated by Fraunhofer ISE and is supported by the following joint project partners – Firmen G.tecz Engineering GmbH, Wendt Maschinenbau GmbH & Co. KG, Priedemann Fassadenberatung GmbH, CAS Software AG, GiB-Gesellschaft für innovative Bautechnologie mbH and TruPhysics GmbH; associate partners – Lindner Group KG and Hans Berg GmbH & Co. KG; and subcontractors – Betonfertigteile Spürgin GmbH & Co. KG, MV automatic GmbH & Co. KG and the Karlsruhe Institute of Technology (KIT).

More information: tabsolar.de

Last modified: