Press Release #27

Fraunhofer ISE Receives f-cell Award 2020

The Fraunhofer Institute for Solar Energy Systems ISE received the f-cell Award this year in the category "Research & Development". The prize distinguished their work on the development of flatbed screen printing as an industrially scalable manufacturing process for fuel cell electrodes. Minister of the Environment, Climate Protection and the Energy Sector for Baden-Wuerttemberg Franz Untersteller presented the award personally during the f-cell conference in Stuttgart on September 29.

Large-scale production research – from innovation to prototype to finished product – will be a driving force for the industrialization of fuel cells. Improved fuel cell performance as well as optimized manufacturability in terms of cost efficiency, speed and reliability will lead to better and cheaper products. In the DEKADE project funded by the German Federal Ministry of Education and Research (BMBF), Fraunhofer ISE advanced the development of screen printing to a scalable manufacturing process for fuel cell production with high throughput and high quality. Two departments at Fraunhofer ISE "Production Technology - Structuring and Metallization" and "Fuel Cell Systems" combined their expertise in photovoltaics and hydrogen technology to achieve this goal. Their submission was entitled "Through-Plane Ionomer Gradients in Fuel Cell Catalyst Layers for Enhanced Power Density."

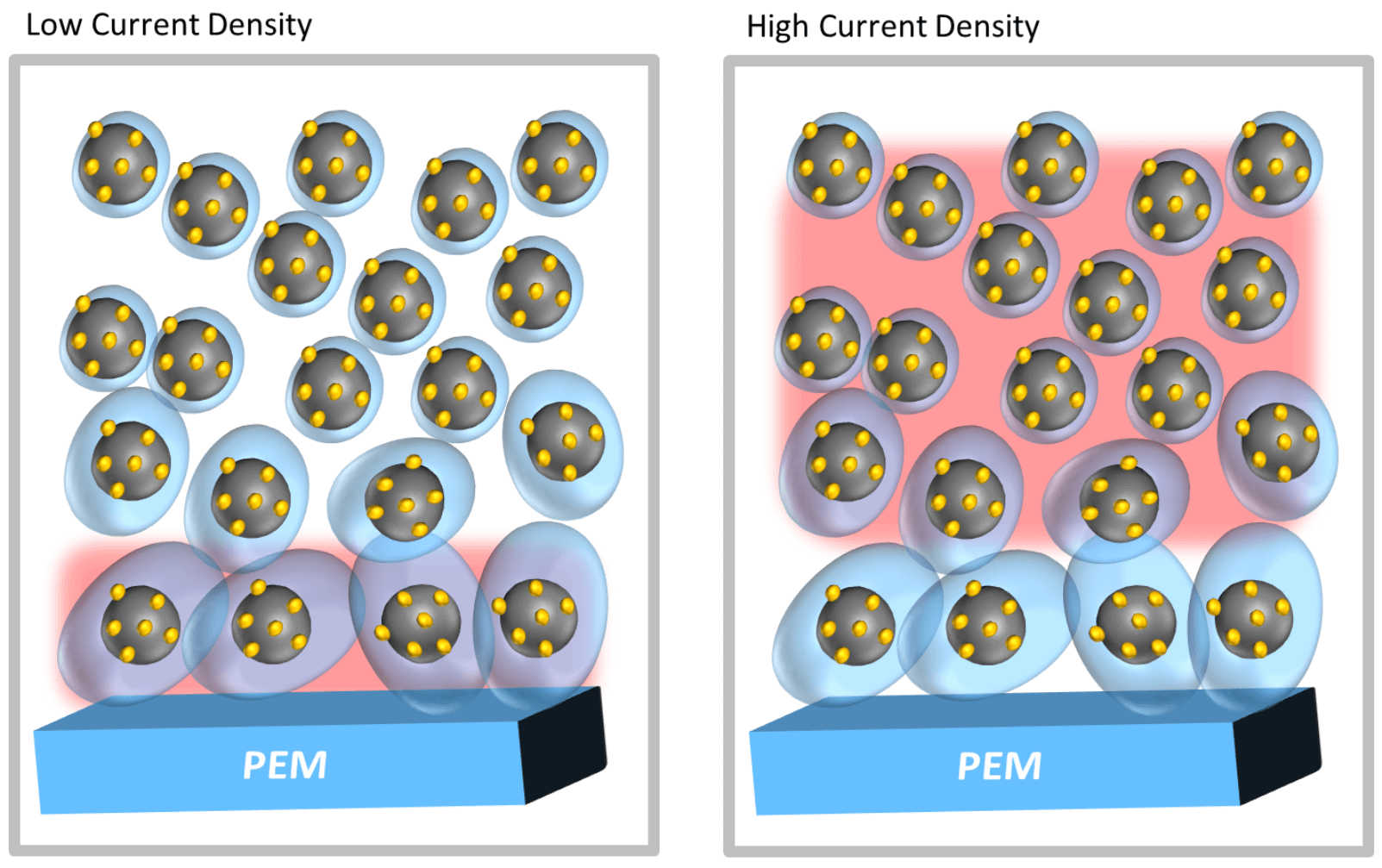

Screen printing – a technology used in the production of solar cells for decades – enables the industrial application of homogeneous layers as stacks and thus the realization of innovative, structured MEA architectures. In this context, Fraunhofer ISE has developed continuous ionomer-graduated catalyst layers, which enable a significantly improved power density during the operation of fuel cells. At low current densities, power generation takes place near the membrane and is not yet limited by insufficient oxygen. For better proton conductivity into the catalyst layer, the ionomer content can be increased here (see figure left). At high current densities, the reactive zone moves deeper into the catalyst layer and the oxygen diffusion resistance limits the power. Because of this, the researchers selectively incorporated fewer ionomers in these zones in order to minimize the oxygen diffusion resistance (right).

This approach led to optimized proton conductivity and oxygen supply. The resulting fuel cell outperformed conventional reference cells that are in the automotive sector by about 10 percent. "This success was achieved without introducing any new or extra material into the production process, which means that performance was improved without any increase in material costs," explains Dr. Matthias Klingele, head of group Cell Analysis and Materials at Fraunhofer ISE, who accepted the award together with his colleague Dr. Roman Keding.

About the F-Cell Award

The Baden-Württemberg Ministry of the Environment, Climate Protection and the Energy Sector and the Stuttgart Region Economic Development Corporation have been supporting the f-cell award since 2001 to acknowledge outstanding developments in one of the most future-oriented technologies – hydrogen and fuel cells – and to foster further innovations.

The prize is awarded in the two categories "Research & Development" and "Products & Markets.” The focus of the criteria is on the degree of innovation, market potential and the benefits for the environment and society.

Last modified: