Press Release #31

24 Percent Efficient n-Type Silicon Solar Cell - Top-notch European research raises potential for cost reductions in photovoltaics

Despite difficult times for the solar industry, Europe remains at the technological forefront in the field of photovoltaics. Fraunhofer ISE demonstrates this fact with its new record: 24 percent efficiency for a silicon solar cell which uses an n-type base material and a novel concept for the rear contact. The special feature of this cell is a so-called passivated contact covering the entire rear surface.

The majority of commercial solar cells today are manufactured from boron-doped p-type silicon. However, due to its high tolerance to most metal impurities, the quality of phosphorus-doped n-type silicon material is significantly better than comparable p-type silicon. Thus, it offers the potential to reach highest efficiencies under industrial production. A decisive hurdle to reaching high efficiencies is, however, the patterning scheme of the rear contact which is used for most of the high-efficiency solar cells. “We have now developed a simple rear contact without any patterning, with which we have achieved an excellent efficiency of 24 percent for an n-type solar cell,” says a pleased Dr. Stefan Glunz, Division Director “Solar Cells – Development and Characterization” at Fraunhofer ISE.

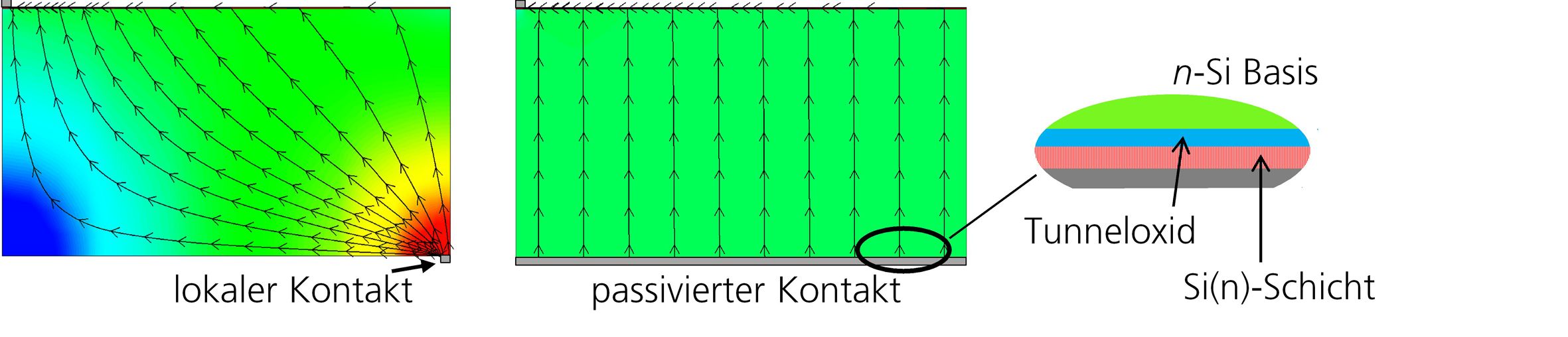

For high-efficiency solar cells, the metal contacts on the rear side are an efficiency limiting factor. Therefore, new concepts, whereby only a small fraction of the rear area is contacted, are introduced today in the industrial fabrication of silicon solar cells. One established example is the so-called PERC (Passivated Emitter and Rear Cell) structure. In this concept, the loss mechanism of charge carrier recombination is reduced by minimizing the area of the metal contact. At the same time, however, the path that the charge carriers take becomes longer, which also leads to power losses. If both these loss mechanisms can be reduced, then there is a greater potential for increased efficiency.

The scientists at Fraunhofer ISE were able to achieve these goals by developing a novel passivated rear contact. “We developed a selective passivated contact that allows the majority carriers to pass and prevents the minority carriers from recombining,” explains Dr. Martin Hermle, Head of Department “High-Efficiency Silicon Solar Cells” at Fraunhofer ISE. The Ph.D. student Frank Feldmann, who recently presented a paper on this topic at the European PVSEC in Paris 2013, adds: “Our new rear contact is called “TOPCon,” which stands for Tunnel Oxide Passivated Contact. TOPCon consists of an ultrathin tunnel-oxide and a thin silicon layer. The surface passivation is of excellent quality and the rear contact poses little resistance for the charge carrier transport.” With the TOPCon structure, we can now contact the entire rear area of the solar cell, while achieving excellent surface passivation and reducing resistance losses to a minimum at the same time.

The research work on the development of TOPCon contacts was supported by the Federal Ministry for the Environment, Nature Conservation and Nuclear Safety (BMU).

Last modified: