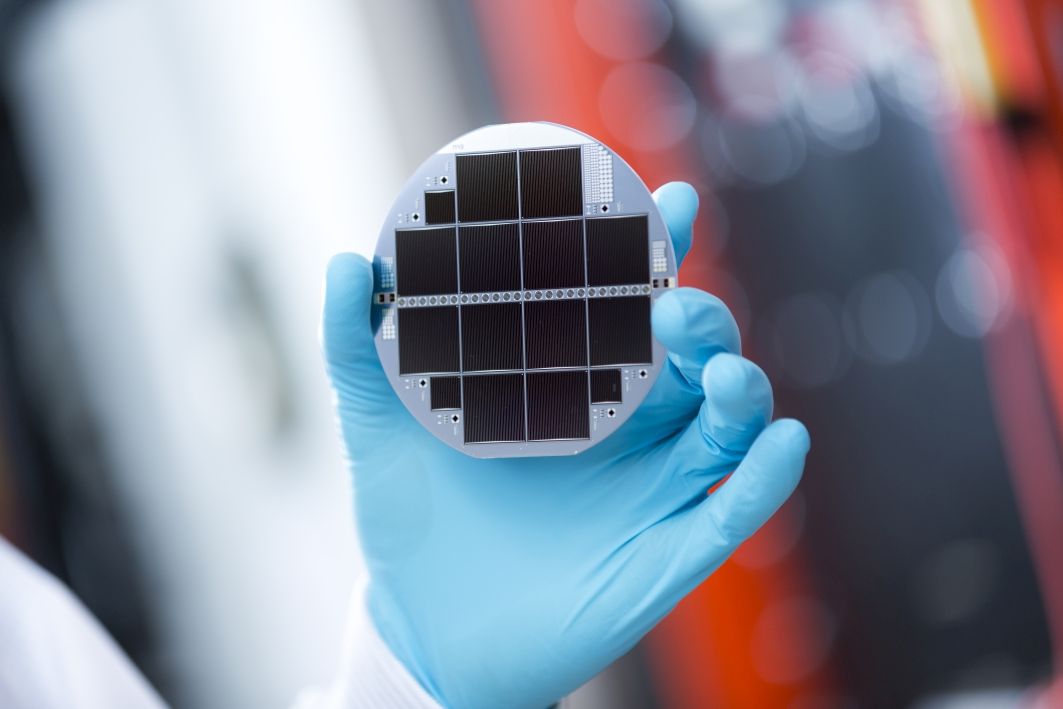

In the business area "III‑V Solar Cells, Modules and Concentrating Photovoltaics", we are working on the most efficient PV technology and looking for economically attractive solutions. The III‑V solar cells we develop are known for their high performance and long-term stability and we continue to set new benchmarks with international record values.

One focus of our research is to reduce the manufacturing costs through new production processes. In addition to requirements from space and concentrator photovoltaics (CPV), we also address solutions for mass markets, such as vehicle-integrated photovoltaics (VIPV) for electromobility.

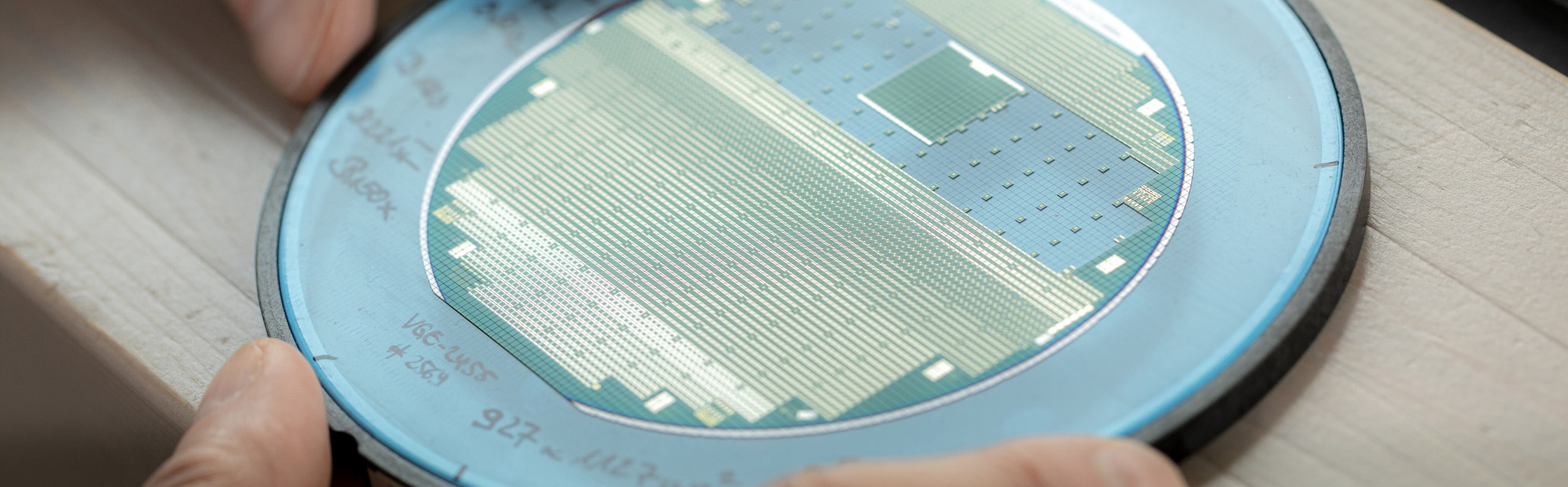

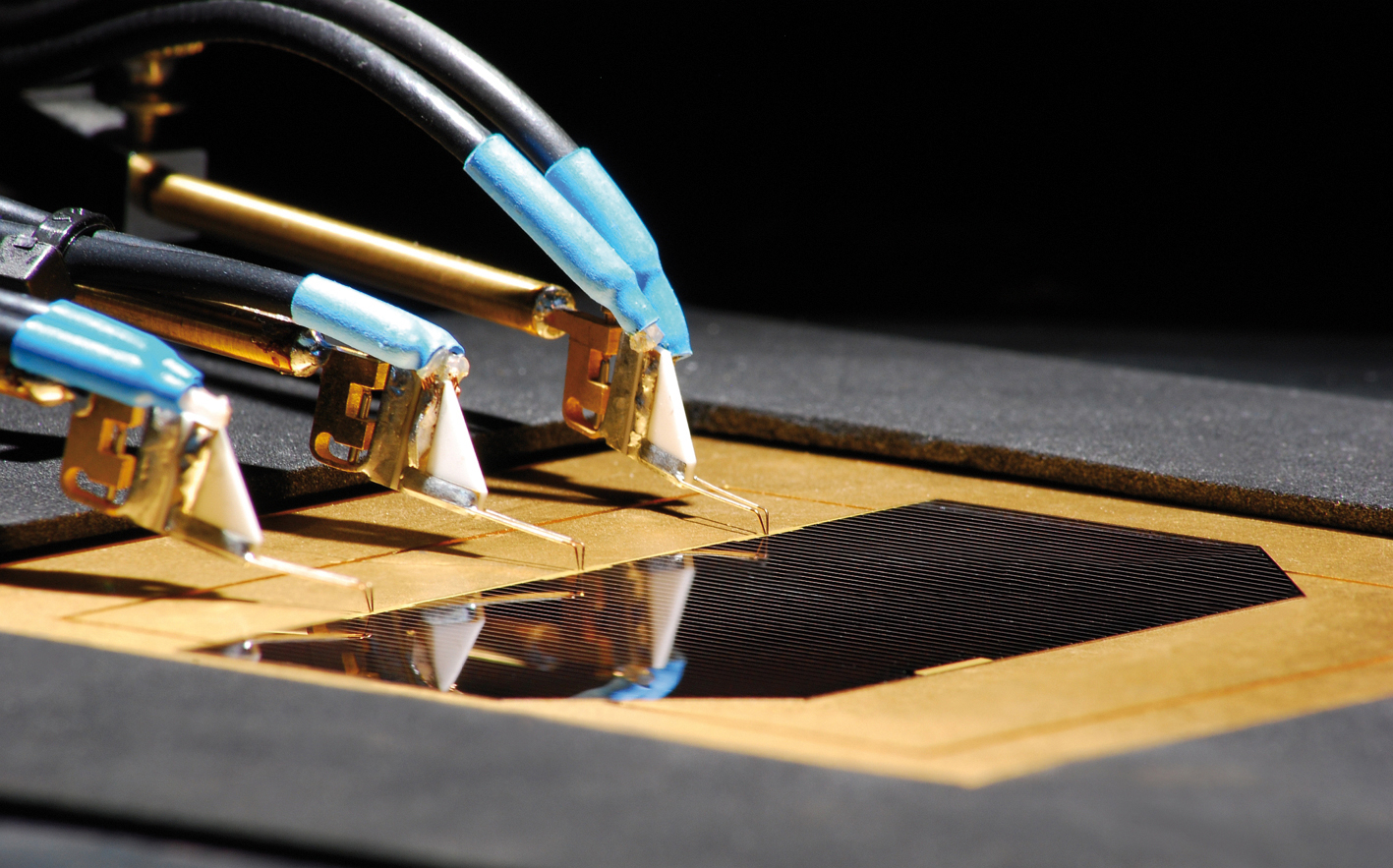

With the help of our excellent laboratory infrastructure, we work both on the development and optimization of next-generation solar cells and on adapting these devices to the specific requirements of our customers. We cover a wide range of topics, such as ultra-thin flexible cells and modules, engineered substrates with different lattice constants, innovative processes for cost-effective cell production, nanostructured mirrors, and advanced measurement technology. In concentrating photovoltaics, we cover all aspects of solar cells, optics, module technology and systems, up to, for example, the production of solar hydrogen. Finally, we use our expertise in the development of photonic and power electronic components for other applications, such as optical power transmission or thermophotovoltaics (TPV).