| Duration: | November 2012 - October 2015 |

| Contracting Authority/ Sponsors: | German Federal Ministry for Transport and Digital Infrastructure (BMVI), National Organisation Hydrogen- and Fuel Cell Technolgy in the course of the National Innovation Program NIP |

| Project Partners: | E.ON Gas Storage GmbH, Hydrogenics GmbH, Solvicore GmbH & Co. KG, DLR |

Compact 1 MW PEM Water Electrolyzer System – Efficient Operation Management of Electrolysers in Power-to-Gas Systems

Hydrogen is a promising form of secondary energy, which can be used in future for a wide range of applications. As it can be generated on a large-scale and CO2-neutral basis by electrolysis of water, electrolysers are key components in the so-called power-to-gas (PtG) concept. Integration of these hydrogen generators into the energy system calls for fundamental understanding of such units. We realistically model the operating behaviour of different electrolysers and power-to-gas systems by stationary and dynamic system simulations and investigate technical and economic scenarios for operation management and system integration.

The continual expansion of renewable energy systems increases the need for options to control the electricity grids flexibly and safely and to store electricity. The power-to-gas concept combines the approaches of active load and generation management with the idea of storing electricity from renewable sources temporarily as chemical energy. When excess electricity is available, it is used in electrolysers to split water into hydrogen and oxygen. The generated hydrogen can be stored temporarily and / or injected into a gas distribution network, to be used later as required in different applications (e.g. mobility, electricity generation, chemical industry).

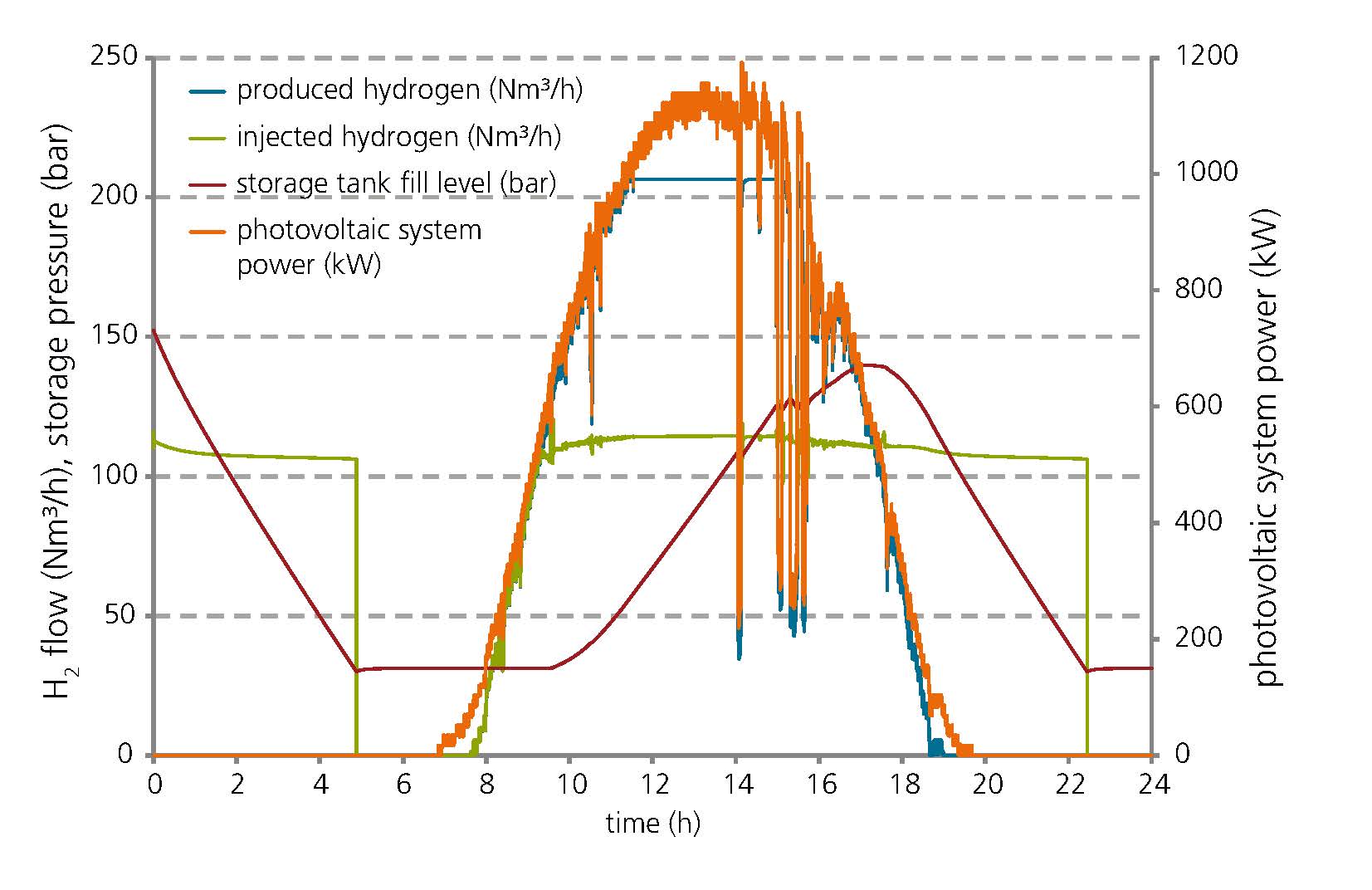

Fig. 2 shows an example for the dynamic behaviour of a PtG system (rectifier, electrolyser, gas purification and drying, compressor, storage buffer and injection valve) which follows the feed-in profile of a PV system. The PEM pressurised electrolyser simulated here is easily able to respond to the daily profile of the PV system. The storage buffer is used to adapt the hydrogen injection to the load curve of the natural gas pipeline. With the help of the simulation tool, we are able to carry out a comprehensive technological analysis and to do preliminary dimensioning of such systems. In further work, the technical simulation will be connected to market models so that various business models can be considered and evaluated.