| Duration: | June 2016 - July 2019 |

| Contracting Authority/ Sponsors:: |

Federal Ministry of Education and Research (BMBF) |

| Project Partners: | Helmholtz-Institut-Erlangen-Nürnberg HI ERN der Forschungszentrum Jülich GmbH; Hahn-Schickard-Gesellschaft für angewandte Forschung e.V.; Institut für Chemische Verfahrenstechnik ICVT der Universität Stuttgart; Institut für Energieversorgung und Hochspannungstechnik der Gottfried Wilhelm Leibniz Universität Hannover |

| Website: | http://www.powermee.de/ |

| Project Focus: |

POWER-MEE – Increase of Lifetime and Performance (POWER) of Polymer Electrolyte Membrane Electrolyzers by High Performance Membrane Electrode Assemblies (MEE)

The central goal of POWER-MEE is to research and develop high-performance membrane electrode assemblies (MEAs) with low catalyst loading and polarization in the electrodes as well as very good transport properties in the electrolyte membrane. A further goal is the investigation and reduction of aging effects in the MEAs.

Fraunhofer ISE is involved in several projects dealing with the aging analysis of commercial standard and newly developed cell components. The aim of this joint project is to reveal driving degradation effects in the newly developed components of membrane electrode assemblies at membrane and electrode level.

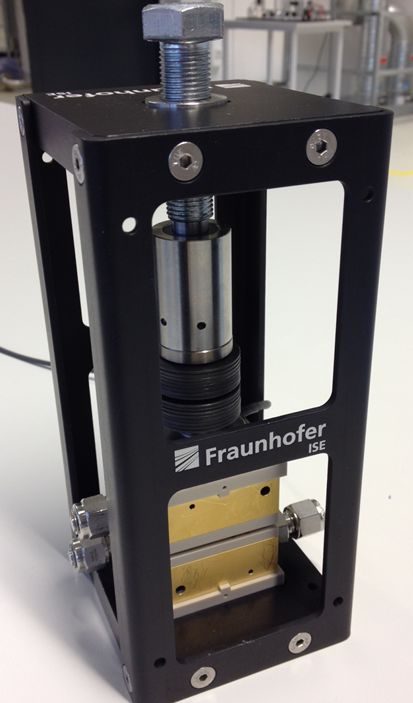

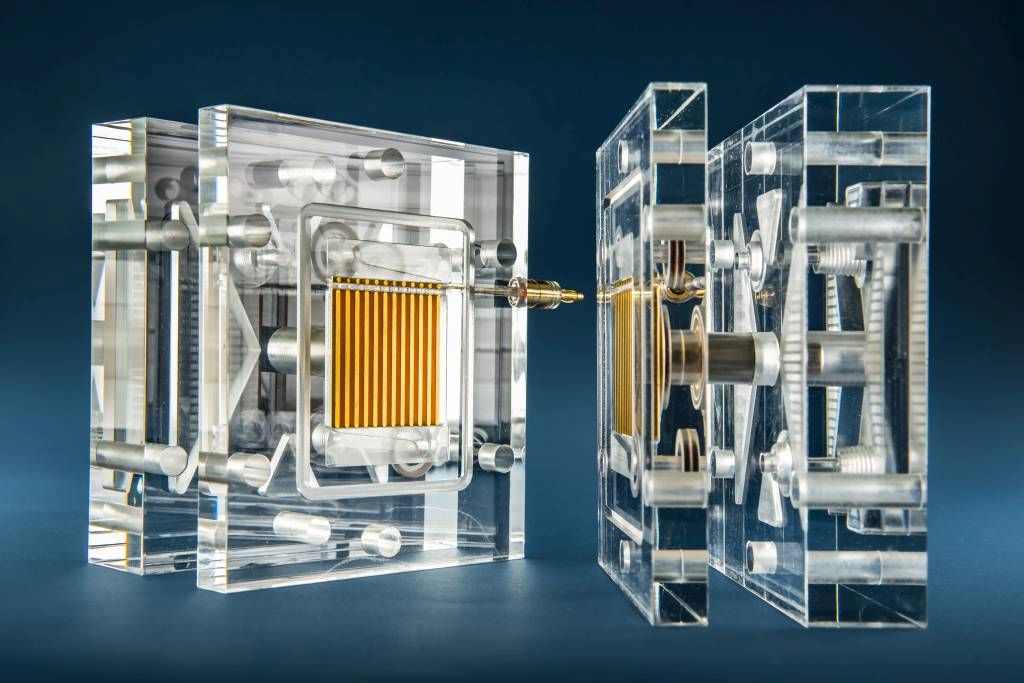

Subgoal 1: Development of new hardware to characterize the MEA. In order to exactly characterize and age the MEA it is important to develop an appropriate test cell. It is of utmost importance that the aging of the MEA is not superimposed by other aging effects of the cell. This requires, for example, the production of corrosion-resistant flow plates. An in-situ characterization of temperatures and overvoltages is desirable in order to validate later simulations of the project partners. The first subgoal within the joint project is therefore the development of an electrolysis cell to characterize the MEA. The active area of the electrolysis cell is initially limited to 4cm² for rapid tests and later extended to 25cm².

Subgoal 2: Development of rapid aging tests. The development of rapid aging tests is essential to verify the long-term stability of cell components within a reasonable period of time. In the project, the aging mechanisms on the level of the membrane electrode assembly are to be identified first. Accelerated aging protocols are to be developed from the known aging mechanisms and test procedures in the fuel cell sector. These will then be used specifically for electrochemical investigations. In combination with the 3D microstructure analysis and electrochemical modeling, a targeted elucidation and quantification of aging mechanisms and performance characteristics in electrolysis can be ensured. The aim is to develop a validated rapid aging test.