| Duration: | 05/2023 - 04/2026 |

| Contracting Authority/ Sponsors: | German Federal Ministry of Economic Affairs and Climate Action (BMWK) – 7. Energieforschungsprogramm der Bundesregierung »Innovationen für die Energiewende« |

| Project Partners: | Photonic System Group, Autarq GmbH, Precitec GmbH Co. KG, Associated without own funding application: Speira GmbH |

| Project Focus: |

Liebesbrief

Laser-Induced Bonding and Micro-Welding Contacts for Better and More Resource-Efficient Series Connection of Flexible Solar Cell Strings

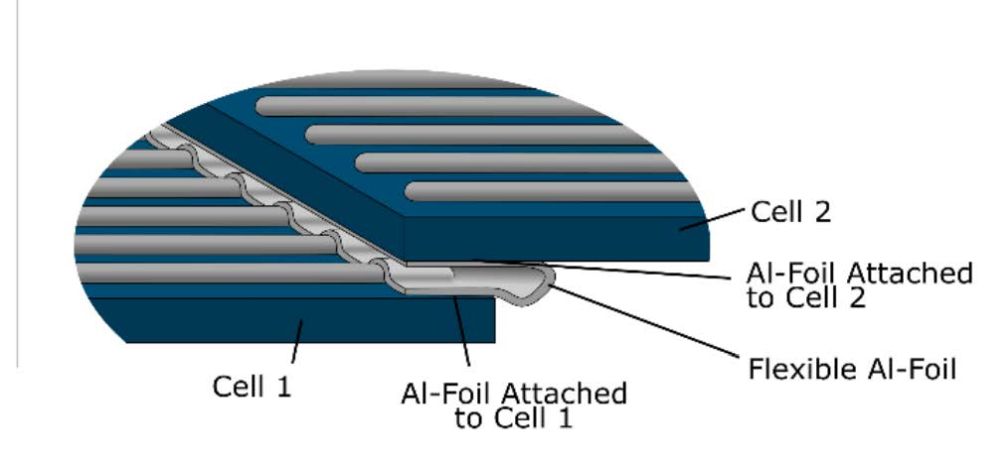

We have been developing laser-based joining processes for thin aluminium foils for the metallization and interconnection of solar cells for over 10 years. Our FoilMet-Interconnect process offers an environmentally friendly, resource-saving and cost-effective alternative to soldering copper wires. In the »Liebesbrief« project, we are working closely with industrial partners to bring this technology to market maturity. We are designing and testing an industrial pilot plant, developing a qualification system for the joints and producing 10,000 special modules that will be integrated into roof tiles in order to extensively test the interconnection technology.

As we enter the terrawatt age and photovoltaics become more widespread, it is becoming increasingly important not only to become more cost-effective, but also cleaner and more resource-efficient. The interconnection of solar cells in particular plays a decisive role here, as large quantities of copper and lead are used. Although the RoHS guidelines (»Restriction of the use of certain Hazardous Substances in electrical and electronic Equipment«) came into force years ago and prohibit the use of lead in the production of electronic components, among other things, there is still an exemption for photovoltaics due to the lack of technological alternatives.Fraunhofer ISE has developed and extensively patented an innovative interconnection technology based on laser-joined aluminum connectors in recent years. This technology makes it possible to interconnect solar cells without the use of lead (or other heavy metals), flux, adhesive and copper. It not only offers an environmentally friendly alternative to the conventional soldering of copper wires, but can also lead to higher module efficiencies compared to the current state of the art.

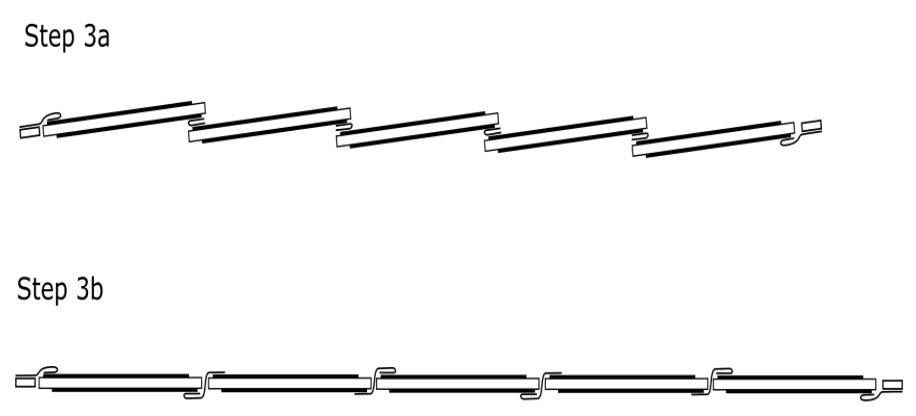

The overarching aim of the »Liebesbrief« project is to further develop this interconnection technology towards market maturity. In collaboration with the Photonics System Group, we are working on a pilot plant to produce such solar cell strings. One of the partial innovations of our approach is the laser-induced bonding of aluminum foil with 0.1 micrometer thin dielectric layers without damaging the underlying absorber. In order to further improve the quality of the joining process, an insitu welding control and joint control system is being evaluated and qualified, similar to that already used in laser-based deep welding processes with thicker joining partners and lower feed rates. As part of the project, 10,000 special modules will also be produced, tested and qualified. These modules will later be processed into roof tiles and subjected to field tests. In addition to the classic topics relating to laser-based interconnection, work is also being carried out on the continuous improvement of laser-split solar cells, which are a global trend. Here, both the cell division by laser is further optimized and a special, also patented post-treatment of the cut edge is developed, as this contributes disproportionately to the losses due to its nature, which in turn are more significant for very small solar cells such as those used in this project.

Links and Downloads

- Laser Technologies (ise.fraunhofer.de)